How long does your shop take to set up a typical job on a CNC lathe or machining center? A few hours? How about half a shift or more? Here are three ways to achieve the not-so-magic number of 15 minutes, a goal that all shops should strive to attain.

One-quarter hour. Some would argue that’s all it should take to set up a repeat job, and they would suggest that some shops achieve this even on virgin parts.

Unfortunately, not enough manufacturers are getting the message.

Do a quick Google search for “reducing setup time CNC” and you’ll see articles dating back 20 years or more, most of which promote the same tooling we’re about to discuss here.

And while technology has improved mightily since that seemingly ancient age, and while the costs for quick-change tooling and offline presetting systems have come down, far too many machine shops are still relying on their old-school setup procedures: tramming in their 6-inch machinists’ vises with a test indicator, performing manual tool touch-offs with the same edge finder they used in trade school, and standing in front of the CNC stepping through programs one line at a time, one hand on the feed rate override and the other hovering over the feed hold and E-stop buttons.

Read more: Career Spotlight: How Do I Become a CNC Programmer?

Make a Pit Stop

That’s assuming those shops are still in business, of course. The painful truth is that production quantities continue to fall, part geometries are growing more complex, and skilled machinists are in even shorter supply than when those now legacy articles were first published. Machine shops that haven’t yet engaged in a setup time reduction program will continue to see their margins fall and their setup times consume more of their available machine time.

So what’s to be done about it? Steve Vice, PIP Lean service engineer for Sandvik Coromant, in Mebane, North Carolina, has several suggestions.

“The best way to start is by assembling a small team of people from your shop floor and the front office,” he says.

“It’s amazing what an office person can see that a shop person might not, but one person cannot do this alone because you need to get buy-in from all involved,” he adds.

“Next, video-record a complete machine setup. Some define this as ‘last completed part to first completed part,’ but others also include the inspection time after the setup. Once taped, have the team review the process and break down all the things they see that waste time. Make changes, videotape another setup, and repeat until you’ve achieved the desired results.”

Read more: Small Parts and Precision Machining: Advice from the Experts on Tools and Techniques

Back to Zero

Vice ticked off several common problem areas, including material availability, machine tool readiness, organization of hand tools and tooling, and whether the workholding has been prepared.

Brad Evans, team lead for stationary workholding at Schunk Inc., in Morrisville, North Carolina, agrees on this last point but adds that achieving maximum setup time reduction in this area requires a shop floor reboot, especially for shops wishing to pursue an automated, lights-out strategy.

The reboot he’s talking about is zero-point workholding, which in Schunk’s case is called VERO-S. With fixed clamping modules and retention knobs resembling those used in steep taper toolholders, zero-point systems eliminate the tramming and edge-finding just described. Work coordinates are predetermined, and changing from a fixture to a vise, pallet or individual part quite literally takes seconds. What’s more, these systems are both modular and stackable, reducing the need for custom fixtures while assuring positioning accuracy to 0.005 millimeters (0.0002 inches) or better.

Schunk has taken this concept one step further by making many of its VERO-S modules automation-ready.

“We’re seeing a lot more cobot [collaborative robots] use and robots out there so have added ports for pneumatic and hydraulic activation, as well as clamping sensors and automatic blow-off capabilities,” Evans says. “We’ve recognized for some time that manufacturing is going automated, and aside from addressing the push for faster changeovers, we wanted to help our customers make that switch.”

Read more: Video: How Has Manufacturing Changed Your Life?

Set It, Don’t Forget It

Dietmar Moll also has a great deal to say about setup time reduction. The director of business development for Ann Arbor, Michigan-based Zoller Inc., Moll offers the following riddle:

“When does a plane make money for the airlines? When it’s not sitting on the ground,” he quips. “Now equate that example with a machine tool. Here again, CNC lathes and machining centers only make money for the company when the spindle is turning and the machine is making chips, not when it’s sitting idle. So if you’re using your expensive machinery to touch off cutting tools and find work offsets, you’re losing money. It’s very simple.”

Yes, but offline tool presetters are expensive, many shops argue, particularly those with only a few pieces of CNC equipment. Moll submits that this argument is flawed.

“In reality, it’s the smaller shops that need a presetter the most,” he says. “That’s because the fewer machines you have, the greater the need to maximize their efficiency. Worse, these shops are most often the ones with the greatest changeover.”

Zoller and other presetter manufacturers provide ROI calculators on their websites. Plug in your shop’s hourly rate and related operating information and you’ll quickly find the investment is in all likelihood a no-brainer. And for those that say, “OK, but we have probing on our machine, so there’s no need for offline presetting,” there’s plenty more to consider.

Read more: Automotive Industry Trends: 3 Things to Watch for in Electric Car Manufacturing

Probing Has Its Place

First off, in-process machine probing is a must-have for part measurement and tool breakage detection during unattended or lightly attended manufacturing. It also serves to determine work coordinates, at least for those who haven’t yet received the zero-point workholding message just given. But for everyone else, it’s merely a way to mistake-proof manual touch-off methods, which does very little to actually reduce setup time.

Read more: Why You Need to Stop Buying Cheap Cutting Tools

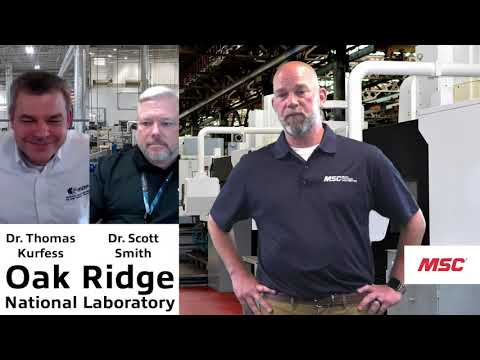

This is why Zoller has partnered with MSC Industrial to offer two low-cost presetting units, the Smile Basic and the Smile 420 Pilot,” Moll says. “The first of these is quite suitable for shops without a centralized tool crib, while the latter will help take them on the road toward one.”

Despite the excellent advice provided thus far, it’s only the tip of the setup time reduction iceberg.

Sandvik Coromant and others offer quick-change toolholding systems, a prerequisite to offline tool presetting on a CNC lathe. There’s toolpath simulation software, which avoids the sometimes heart-stopping program prove-outs described at the start of this article. There are standardized cutting tool libraries, and automated shop-floor CMMs (thus eliminating the QC room bottleneck), and well-organized tool cribs with software-driven dispensing units.

The list goes on and on, and as pointed out earlier, most of it has been around for decades. So what are you waiting for? Get counting.

Making a Pit Stop

Steve Vice, Sandvik Coromant’s PIP Lean service engineer, thinks shops can learn a lot from Indy and NASCAR race teams.

“A typical pit stop might take 6-10 seconds to lift the vehicle, change four tires, fill the fuel tank, clean the window, and give the car a quick check for loose or broken parts,” he says.

“They didn’t achieve that efficiency on their first try, or even their hundredth,” he continues. “It took many years to perfect what they do, and even though they’ll never get it to zero, they keep improving on what they have. That’s how you win the race.”

Related Articles

The Latest Tools and Techniques in Metal 3D Printing

HOW TO Put Innovation to Work for You

VIDEO: HOW TO Implement Grinding Solutions with Automation

Smart Restrooms: Companies See Value in IoT Connected Dispensers