Zero Scrap and Performance Upgrade

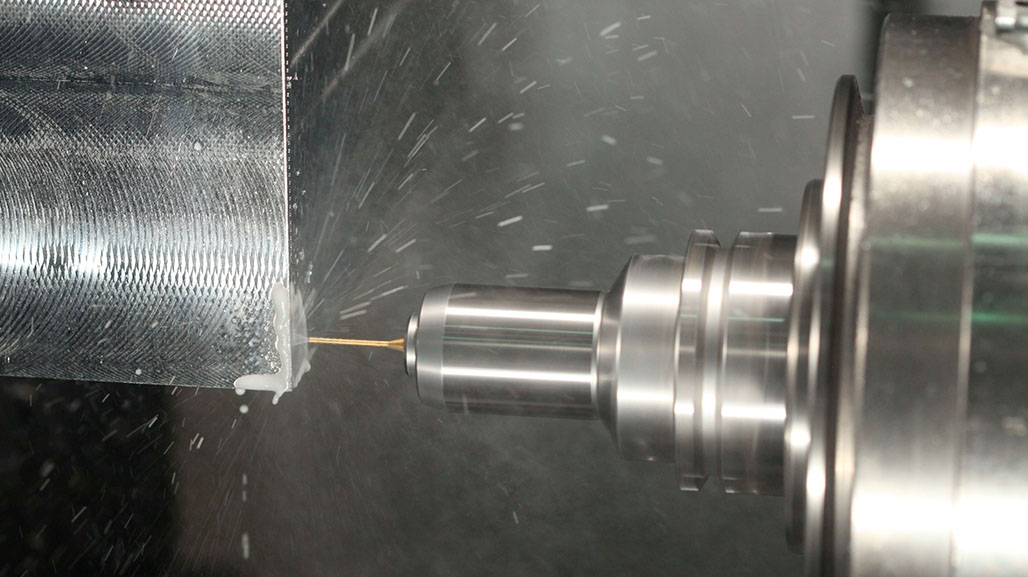

Gulfco Manufacturing eliminated tap breakage and improved tool life by switching to OSG’s AT‑2 thread mill, achieving more consistent machining performance in 17‑4PH stainless steel components.

Discover expert insights, industry trends, how-tos, and product tips to boost efficiency, cut costs, and improve operations - all in one place.