Whether you’re creating an aerospace blade, an automotive cylinder head or a valve on a ventilator, precision in manufacturing is crucial. Here’s what you need to know about precision measurements in manufacturing.

The need for precision measurement has existed for as long as humans have been going places and building things. Without it, there would be no way to brag about the distance your army marched, the height of the pyramid you built, or the expanse of your arable fields.

It wasn’t until humans began mass-producing interchangeable components, however—firearms and parts for machinery, primarily—that accuracy became equally important to manufacturers and those who use their products.

Accuracy? Precision? What’s the difference? To borrow from a popular illustration, a precision archer can repeatedly strike the same area on a target, even if that spot is nowhere near the bull’s-eye. An accurate shot, on the other hand, is one that hits the bull’s-eye, regardless of whether the next shot goes astray. The person who takes home the prize is the one who can achieve both—precision and accuracy—a qualifier that’s as true for the archery range as it is the production floor.

Read more: When to Upgrade Your Drills: Solid Carbide Has Come a Long Way

The International Language of Measurements

Discussions such as these fall under the purview of metrology, the science of measuring. Metrologists will tell you that determination of any object’s accuracy (how close it came to the target) and the precision of the process used to manufacture it (how often it can repeat that performance) requires a system of universally accepted standards.

It also requires units of measure traceable to immutable—but well-understood—physical phenomena. For example, the International System of Units (SI) defines 1 meter as the distance that light travels in a vacuum in 1/299,792,458 of a second, with similar standards for time, temperature, mass and more.

A broad assortment of such quality standards and organizations exists. The American Society of Mechanical Engineers (ASME), for example, promotes the American National Standards in dimensional metrology, also known as B89. Similarly, there are various standards from the American National Standards Institute (ANSI), ASTM International, and the International Organization for Standardization (ISO). Add to these the whole imperial vs. metric discussion (aka the United States vs. everyone else), and you quickly see why metrology and part measurement can be somewhat confusing, even to the experts.

Read more: Managing Downtime: A Guide to Improving Shop Productivity During Manufacturing Slowdowns

Meeting these standards takes effort. Manufacturers of all sizes and specialties work hard each year to achieve their ISO 9001:2015 quality certification. If you’re in the aerospace industry, you must also comply with AS9100, a document published by the Society of Automotive Engineers (SAE) and the European Association of Aerospace Industries (AECMA). Medical device manufacturers are required to meet the quality standards described in ISO 13485, while automakers have long followed ISO/TS 16949 (but must now transition to the International Automotive Task Force’s IATF 16949 standard). No certification or adherence to these standards, no work.

Measuring Technology’s Dramatic Shift

As with most manufacturing activities, metrology is a complex field. And while shops might welcome a little harmonization and simplification, none will argue with the importance of adhering to robust quality standards. Without it, parts don’t fit, products fail, company growth (and occasionally, human lives) are in jeopardy. That’s why manufacturers should work diligently to understand and comply with whatever standards apply to the types of parts they make and industries they serve. Doing so means reading the relevant documentation, taking classes or seminars when available, meeting one’s self-imposed quality guidelines, and leaning on experts as needed.

One of these is Dan Skulan. The general manager of industrial metrology at Renishaw Inc., he says that measuring technology is undergoing a dramatic shift as manufacturers everywhere try to do more with less.

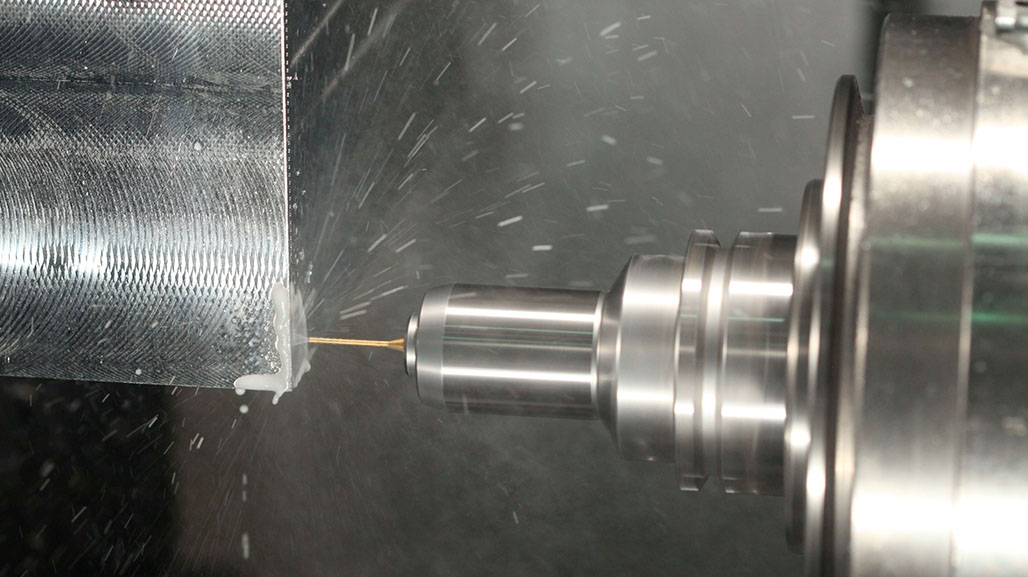

“The days of having someone standing at the machine, micrometer in hand, are going away,” Skulan says. “More and more shops are putting CMMs (coordinate measuring machines) and multipurpose gaging systems like our Equator on the floor, or using touch probes in CNC machine tools as an integral part of the machining process.”

These types of automated inspection technologies increase flexibility while reducing costs, he adds. Because a single device can perform multiple measurements, there’s less need for the dedicated hard gaging long used throughout the industry. And since these systems don’t make human mistakes like forgetting to check a part feature or record a dimension, the quality control process is more consistent and reliable. Further, dimensional feedback is automatic and immediate. Humans can also be alerted to take action when values stray from nominal, or the device can even shut the machine tool down if necessary.

Patrick Sullivan, strategic distribution sales specialist at Mitutoyo America Corp., sees things a little differently.

“Automation has been an ongoing trend for years, but that type of manufacturing is not right for everyone or every part,” he says. “There is very much a place for skilled machinists who can operate a machine tool and take accurate readings with manual measuring tools, giving them the ability to make the right decisions on the fly that no robot can. Not only can today’s machinist work to improve processes on the shop floor, with the help of data collection transmitters the quality department can also receive good, reliable data and work to be more proactive on addressing manufacturing challenges.”

Read more: Thinking About Getting Into Live Tooling? Here’s What You Need to Know

Metrology Tech: The Latest Digital Developments

More automated inspection devices aren’t the only dramatic shift; parts are changing as well.

“Automotive is shifting to electric vehicles, with batteries and motors and sensors that we’ve never had to measure before,” says Mitutoyo’s vice president of sales, Michael Creney.

“At the same time, several key industries are tightening their requirements. Medical manufacturers, for instance, need electronic signatures, audit trails and specific login credentials to meet FDA guidelines,” Creney continues. “And the aerospace industry is pushing hard on digital twins and model-based engineering. Because of this, an increasing number of CAD models now contain product manufacturing information (PMI), which we can leverage in our MeasurLink, MiCAT Planner and other types of quality software.”

Here comes yet another acronym: QIF, short for quality information framework. Creney suggests that QIF can be thought of as the successor to DMIS (Dimensional Measuring Interface Standard), the quasi standard under which CMMs and other automated measuring equipment have long operated. Yet this decades-old language is beginning to evolve as a) measuring systems become more automated, and b) a greater wealth of digital information becomes available.

“DMIS is a specification that everyone interprets differently, and that lacks the robustness needed in a digital manufacturing environment,” he says. “But QIF is a whole different world. The ability to import a CAD file and have your quality software extract relevant dimensional and tolerancing data, then use it to create an automated measuring routine—it’s a huge development, and is something that we fully support. QIF is going to change everything.”

Common Types of Workshop Measuring Tools

From plumbers to aircraft mechanics, all tradespeople need various hand tools to do their jobs.

This is especially true for machinists, tool and die makers, and sheet metal fabricators, all of whom must measure the parts they produce.

Here’s a quick rundown of the tools you might spot while touring a typical shop’s inspection room:

Micrometers are tools that generally fit in a person’s hand and are used to measure inside and outside diameters, hole depths, thread and groove dimensions, and so on. Together with 6-inch dial (or more likely digital) calipers, these are among the most common of all inspection tools.

Hard gages, such as pins and rings, are often employed for Go/No-Go checking of parts. A pair of gage pins, for example—one at the upper tolerance band, the other at the lower—is a quick way to verify whether a hole meets dimensional requirements.

Gage blocks are another type of hard gage: one that’s typically used to set or “calibrate” other inspection devices like bore gages and micrometers.

Dial, test and travel indicators measure the distance traveled by a movable tip when placed on a workpiece. They are also used to transfer readings from a workpiece to a height master or “Cadillac” gage.

Surface plates are large, super-flat, square or rectangular hunks of granite or sometimes iron that serve as an inspection datum. The height gages and dial indicators just mentioned are often found sitting here.

There are plenty more. Bore gages play an important role in most holemaking operations. Optical comparators, or “shadowgraphs,” provide a magnified view of a workpiece’s exterior, allowing for quick, easy measurements. You’ll use a profilometer for measuring surface roughness, roundness devices for checking shafts and holes, CMOS-equipped vision machines for measuring visible part features, and the king of any shop's inspection room, the CMM, or coordinate measuring machine.

Related Articles

Tech Tip: A Hydraulic Chuck Quick Guide

Microfiber Tech: MFT PRO Gloves Pair Comfort and Performance

Reliable Secondary FR Gear for Chemical Protection

Best Drill Bits for Stainless Steel: Advice from Those Who Know It Best