What You Need to Know

Safety is a top priority for shop owners.

There are several tooling solutions and best practices for dealing with problematic chips.

The important thing to remember when choosing chipbreakers is to match the chipbreaker to the application.

Safety is a top priority for shop owners, and we’ve seen significant improvements by Seco customers in development of workplace safety procedures and better training. As an example, when Seco sales reps visit your facilities, they are often required to watch a safety video before even going onto the shop floor.

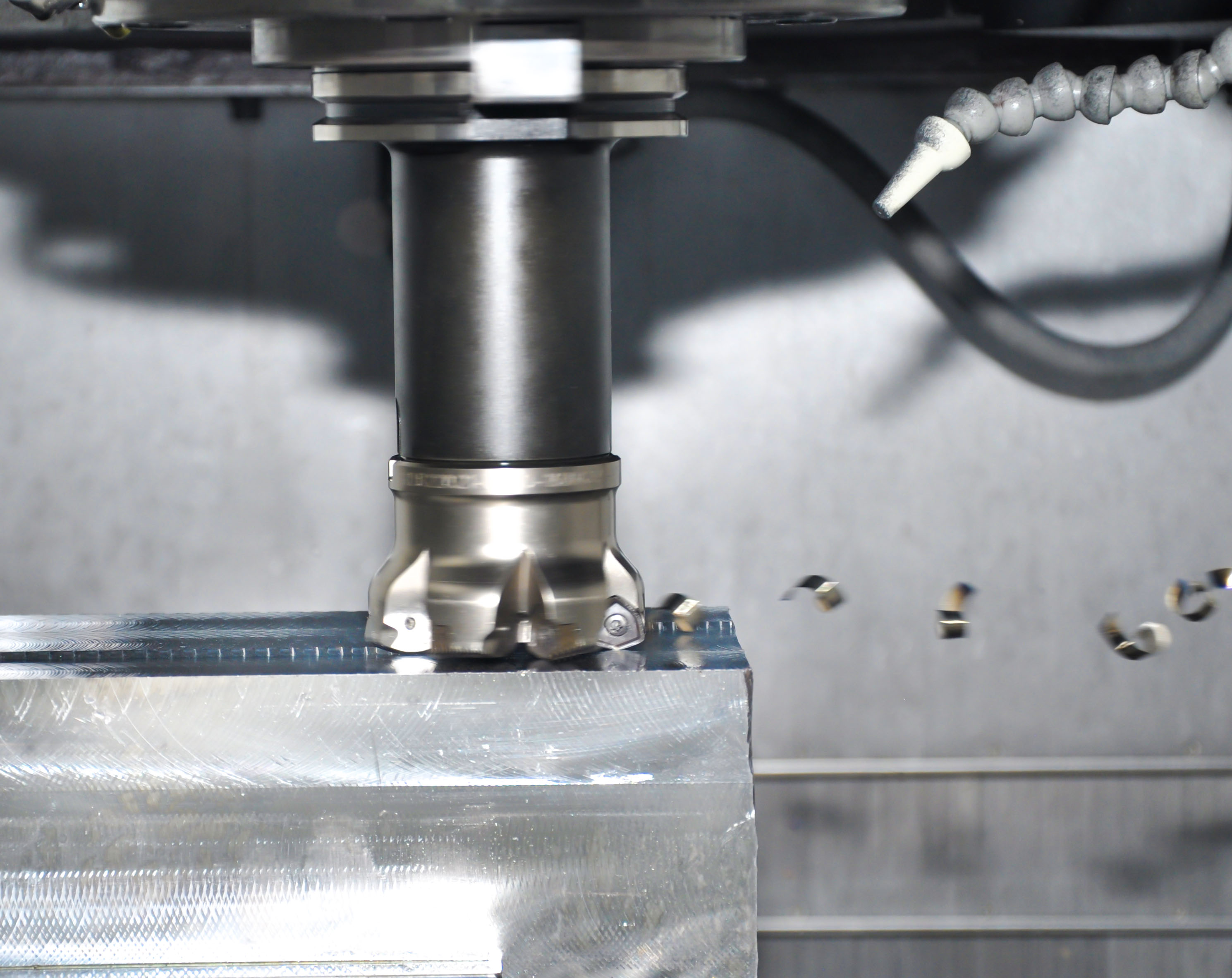

One area of focus in many shops is better chip control. Usually when we think of chips and the problems they cause, surface quality and productivity issues are first to come to mind. But more shop owners are becoming keenly aware of the safety hazards chips cause and understand that the best form of precaution is to control chip formation.

When machining materials with low amounts of carbon, such as mild-steel and austenitic stainless steel, it’s common for long, stringy chips to form and tangle around the tool and workpiece forming “bird nests.” Operators must stop the machine to untangle the chips from around the tooling, which can be dangerously sharp. They also must frequently empty chip hoppers. Anytime a machine operator reaches into a machine, there is potential for an injury to occur. Alleviating the need to clear chips reduces this risk.

There are several tooling solutions and best practices for dealing with problematic chips. First, let’s look at chip-breaking technology. There is a good selection of chipbreaker insert geometries available today. These effectively control the formation of chips so they break off and move out of the cutting zone. For example, there are finishing chipbreakers that are specially designed for smaller depths of cut less than 0.060" and low feed rates of 0.003"-0.012" in/rev. These chipbreakers are narrow in the front and have a pit or dimple and a very large rake angle at the nose. There are also chipbreakers designed specifically for roughing which typically have negative T-lands for edge strength and for breaking chips at heavier depths of cut.

The important thing to remember when choosing chipbreakers is to match the chipbreaker to the application. To be effective, you must create the right combination of tool geometry, cutting speed, feed rate and depth of cut for the workpiece material.

It’s best to follow the general rule of running cutting tools at their maximum allowable depths of cut to create the more desired comma-shaped chips that break off and quickly evacuate. Smaller depths tend to produce spiral-shaped chips, which don’t behave as nicely.

Likewise, chip breaking can be improved by optimizing the feed rate. In most cases, to ensure ideally shaped chips, the minimum feed rate in turning applications should not be less than the chipbreaker’s recommended feed rate, and the maximum feed rate should not exceed the tool’s nose radius.

Another way to control chips is by using a direct coolant system, which can effectively increase chip removal. Seco Jetstream Tooling™ channels coolant directly to the insert through small-diameter apertures to produce an acute high velocity “jet stream” that penetrates the precise friction zone between the cutting edge and the workpiece. The result is superior lubrication, cooling and chip removal.

As you search for ways to improve safety on your shop floor, be sure not to overlook your chip control strategies. Contact Seco to learn more about the assortment of chip control solutions.

Key Takeaways

Safety has become an increased priority for shop owners.

Chip control has become a focus area where improvements can be made to increase safety.

There are many simple solutions to deal with problematic chips.

Brought to you by Seco Tools

Seco Tools is your complete metalworking solutions provider offering cutting-edge, precision tools for indexable milling, solid milling, hole making, turning, threading, grooving and more. We’re proud to make for makers, invent for inventors, and partner with pioneers. In short - if the right tool for the job exists, we’ll deliver it. If it doesn’t, we’ll create it.