KYOCERA SGS Precision Tools (KSPT), working alongside a distribution partner and this end user, helped realize a cost savings in excess of $100,000. However, the confidence from the end user in this particular case was not easily obtained. Building on application engineering support from the KSPT Global Innovation Center, field sales professionals from their supplier and KSPT was able to greatly improve the customer’s process without sacrificing finish results.

GOALS

To produce 550 large dimension ring of 6AL4V titanium for an engine turbine of a commercial aircraft company. A reduction in cycle time and boost in tool life was desired in order to meet production capacity.

STRATEGY

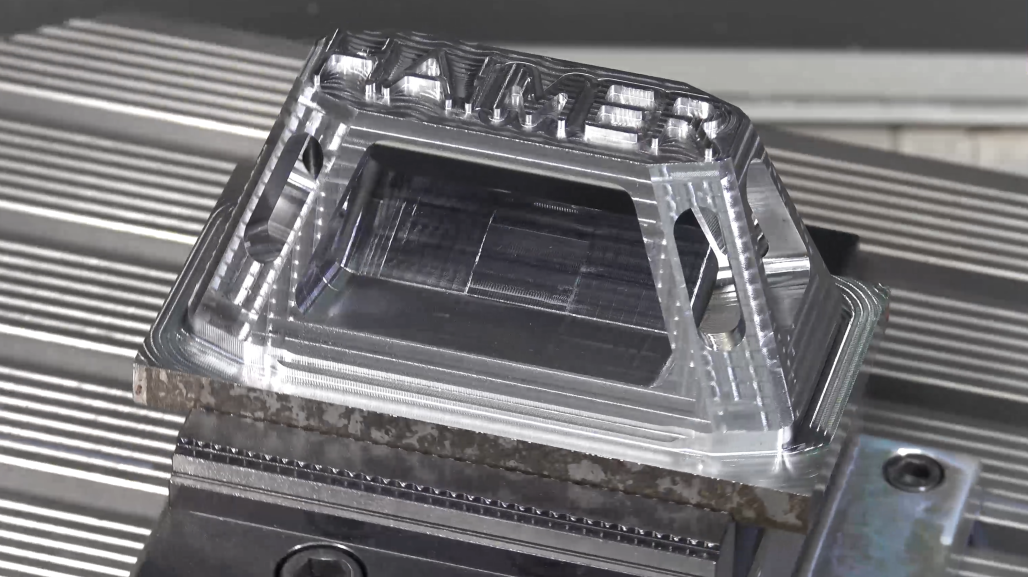

Identical cut parameters were given to both KSPT’s Series 55 V-Carb® and the competitor’s tool: a finish operation with a radial pass of .025” and an axial cut of 4.0”. These high performance five-flute end mills, with their unequal helix, unequal indexing and optimal rake and relief combination offer unmatched finishing capability. The application of the V-Carb® (1.0x4.00x7.00 CR.197) was ultimately the deciding factor in this case. An improvement in speed and feed, material removal rate and over tool life were anticipated, and ultimately realized.

RESULTS

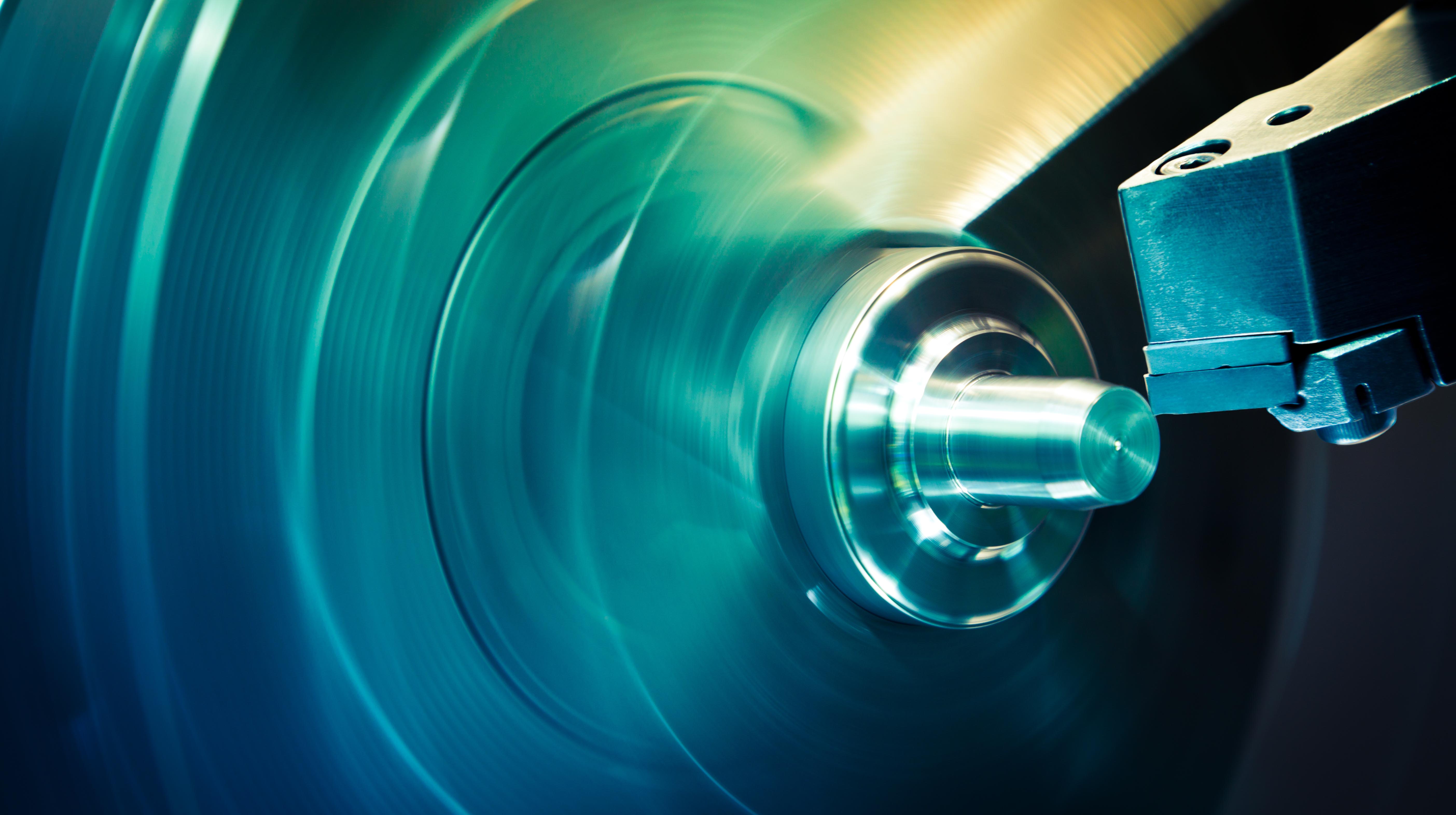

The results utilizing the Series 55 V-Carb® were statistically heavily in its favor. The customer was able to run the V-Carb® at a 30% increased speed as well as a 27% increased feed rate. With these increased efficiencies, the customer experienced a major increase in tool life with the V-Carb®. So much so that the new tools required to complete the customers desired 550 parts were half of the amount needed by the competitor. The total machining cost was lessened by over $3,000. The total new tool cost was lessened by over $100,000. This all led to a total cost per part reduction of almost $200. When all was said and done, the total cost savings equaled $109,765.56!!

SOLUTION

An adjustment of the cutting parameters with a vastly superior tool ultimately provided the customer with a solution to their challenge of a reduction in overall cost without sacrificing quality. With the help of KSPT’s highly trained technical team at their Global Innovation Center, a substantial partnership with this end user was forged.

To learn more about the potential benefits of the Series 55 V-Carb® for your operations, click here to view a PDF of the complete Case Study.