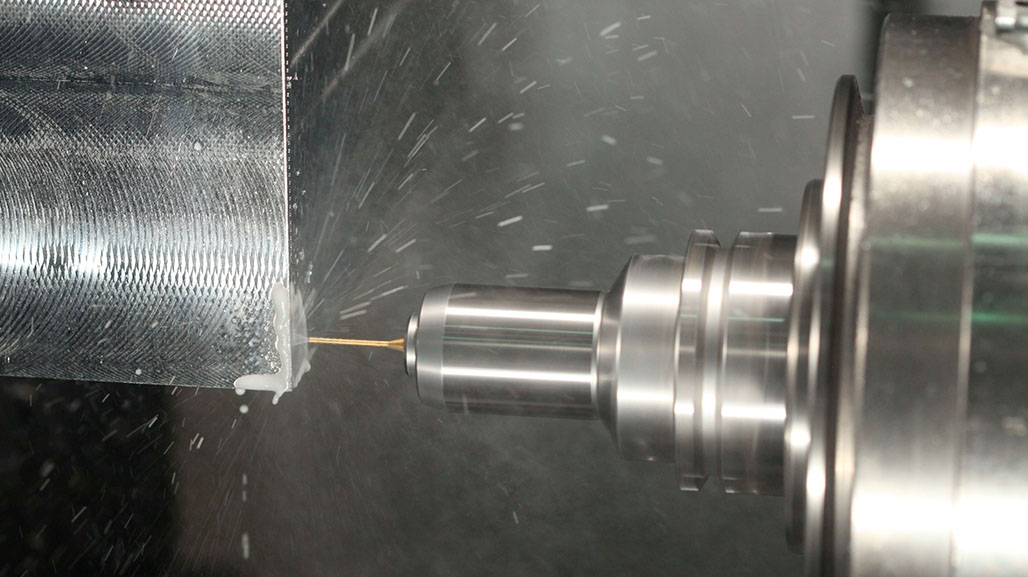

HOW TO Finish the Job with Automation

What does it take to deliver a flawless finish every single time? In this episode of MSC Industrial Supply’s How To series, host Jacob Sanchez visits Norton’s Abrasive Process Solutions (APS) Lab to see how automation is transforming the final step in manufacturing: surface finishing.