How Machinists Will Adapt to Automation: Programming Skills

Machine programming skills have never been more important to the future of precision and advanced manufacturing. Read why.

Machine programming skills have never been more important to the future of precision and advanced manufacturing. Read why.

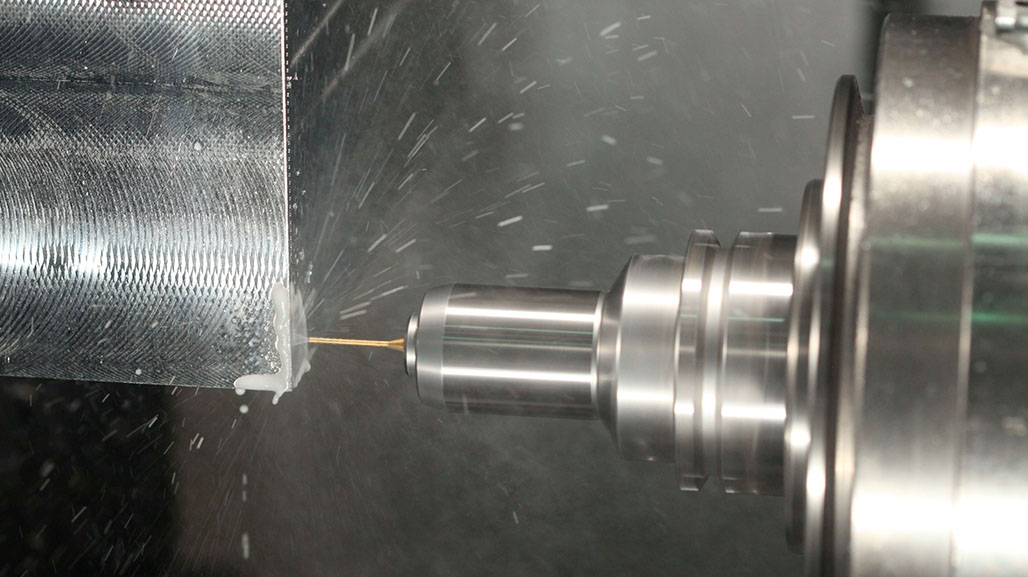

Programming is at the heart of much of today’s machining. Keeping up to date and committing to lifelong learning are essential regardless of where the industry is headed. Is the machine programmer of the future a code developer, a systems integrator or an enabler of artificial intelligence?

How automated will machining become in the future? How canned, or “feature-based,” will machining functions become?

Some argue it will have to go more in the feature-based direction to account for the expected scarcity of skills. Automation is happening—but it requires human intervention to maintain, troubleshoot and program. Will the industry become completely run by automation? Not likely.

“There’s a great dishwasher analogy someone brought up to me: In my lifetime, I don’t believe you’ll ever see your dishwasher unload automatically because there’s expertise and complexity that goes into loading and unloading,” says Dr. Thomas Kurfess, a professor and the HUSCO/Ramirez distinguished chair in fluid power and motion control at the Georgia Institute of Technology, in a Q&A with Better MRO.

“The same thing goes for machines––we need to make the machines easier to use by helping the programmer make choices such as which tool to use and what orientations to program in full 5-axis continuous modes,” Dr. Kurfess explains.

Programming languages themselves may evolve to take more advantage of the computing power in graphics processing units, or GPUs, like you see in high-end gaming systems. Some machining might become easier—but to stay on top of skills and earn higher take-home pay, programming and a deep understanding of technology have never been more important to machinists.

Better MRO talks to industry and academic insiders about programming—and other skills and technologies affecting the industry.

Cutting strategies, cooling, CAM software, machine tools and many other areas of machining are consistently evolving. And so is the integration of all these things to allow them to work together.

Technology is not always on the same timeline: CAM software may not be ready for the latest machine or cutting tool innovation, so it’s up to the programmer to understand how to best manipulate and refine the geometries needed, explains Ronnie Brittain, a CNC instructor at NASCAR Technical Institute, which is part of Universal Technical Institute.

“I think one of the biggest challenges that CNC technicians face today is trying to integrate automation into the process,” Brittain says. “So maybe you have a robot or a gantry loader that’s loading or unloading a machine moving a part from here to there. It has to also be able to communicate with a CNC machine tool. Those two programming languages are quite a bit different.”

Brittain has also worked for a highly automated automotive maker and witnessed firsthand how robotic technicians and CNC programmers would have to work together to troubleshoot issues in integrating the systems.

“It seems like more and more companies are trying to work toward having that be a one-person job … So they are asking machinists to understand more and to up their skills and understand how to make things work together, between robots, CNCs and all the different machines that are out there,” Brittain says.

Robotics are making their way into the smaller job shops too—mainly to help keep up with production demands and to keep machines running 24/7 in a “lights-out” capacity, Brittain says. It requires a different programmer’s skill set to create that kind of automation.

“The challenge that we face in manufacturing, specifically in programming today, is variability … When I look at the number of tools-to-geometry ratio, there are infinite number of ways to cut parts,” says Jason Ray, CEO of Paperless Parts. “A lot of people think that there are so many unique geometries of parts and so many different variables of geometry. I would say there are a lot, but typically job shops specialize.”

Ray thinks the industry will start to see more and more data and machine learning applied to standardized data sets, such as toolpaths and geometries, which will make things easier.

Do you need a technical question answered? Ask the MSC Metalworking Tech Team in the forum.

In the near future, data is expected to help drive the business decisions that make life for job shops easier and more efficient. Not that data itself is anything new for manufacturing.

“[M]anufacturers have long been confronted with huge amounts of data flowing throughout their organizations,” writes Eric Fogg, co-founder of MachineMetrics, in a blog post. “The challenge, however, has been to identify a practical way to leverage that data so it can be transformed into a competitive advantage—instead of just having it sit on servers taking up space.”

Experience, rather than data, drives decision-making and competitive advantages for most job shops today, Ray says.

“That’s because data has not really been accessible before, because it’s been very siloed. But as we move more towards cloud solutions, we’re going to be able to look across data and look across machining strategies to know that a specific cutting tool performs a specific way and a specific machine is at a specific spindle speed,” Ray says.

It’s beginning to happen. Ray points to another example: BlueSwarf performs machine vibration analysis—which can help pinpoint harmonic signatures and help manufacturers better understand specific and unique machine capabilities on the shop floor.

“I do believe you will start to see these Lego building blocks similar to the way you saw human interaction with code and Python code snippets. These Lego building blocks will start to be more prolific. You’re going to have people using them more and more when the same cutting strategies are applicable,” Ray says.

Go deeper. See how the demand is up. Read “CNC Machine Programming: Advanced Skills Are in Demand.”

Technology skills and technical skills can really help today’s job shop machinists earn more. Push-button machining has come and gone. What does it take to earn more today and in the future? The continued pursuit of technical knowledge.

“A highly skilled employee with a great amount of technological knowledge becomes a huge asset to most shops, not because the owner is itching to dump money in your pocket; far from it,” writes Colin Gilchrist, a Mastercam consultant and CNC programming expert, in a post on LinkedIn’s Pulse. “You become an asset to them by making them more money. And you make a shop more money by producing parts better and faster than the shop next door. I make the high salary I do because I have many skills that others do not; my knowledge makes me valuable.”

Gilchrist has written a number of articles on LinkedIn sharing his experience and knowledge—with a flair for explaining what it takes to separate your skills from the pack.

He often talks about the value of lifelong learning and the importance of teamwork on machining teams. He also does not shy away from talking about technology skills needed, including learning G-code, M-code and Macro B, which is programming language for machine controls.

Macro B allows machinists to “store and retrieve variables” including tool lengths, cutter radius compensation values, work offsets and parameter settings.

“Using Macro B and writing logic into your program will allow you to do things like ‘loop until a condition is met’ or ‘jump to another location when a condition is met,’” Gilchrist notes. “In many cases, you can set up a test to check for issues on the machine and sound an alarm to alert you to a problem or potential crash.”

How is your job changing? Do you need to be more of a code developer or interpreter? Talk about it in the forum. [registration required]

The technologies around today’s machining languages are getting more complex, but the language mostly being used: G-code.

“[I]n all honesty, we haven’t necessarily improved our programming capabilities from the 1980s on the machine, and we still have a very complex task requiring a highly trained programmer with a significant amount of experience,” says Dr. Thomas Kurfess, a machining expert at the Georgia Institute of Technology. How will it change?

In that Q&A with Dr. Kurfess, he says he’s been experimenting with automating toolpaths using 3D pixilation technology, also called “voxels,” that performs digital volumetric processing, which is a natural format for a computer graphics processing unit, or GPU. This approach lends itself well to machining parts and to hybrid machines, which combine additive on machine tools.

But there are other advances too.

“Making it easier for a human to communicate intention to a machine, that’s going to evolve,” says Jason Ray, CEO of Paperless Parts. “I think we are also going to see parametric toolpathing come to life more too.”

The industry is beginning to see voice-activated, human-to-machine intelligence make its way to the shop floor with the Athena platform. Ray also points to SolidWorks’ recent advances in its parametric product that forecasts metal cutting for machinists.

“We still view machinists as tradesmen today, and not robotics programmers,” Ray says. “The machine programmer of the future is a code developer. You’re writing code to tell a robot to manufacture a component of another robot. That is a pivotal change in the way we think about a position inside a shop.”