Best Drill Bits for Stainless Steel: Advice from Those Who Know It Best

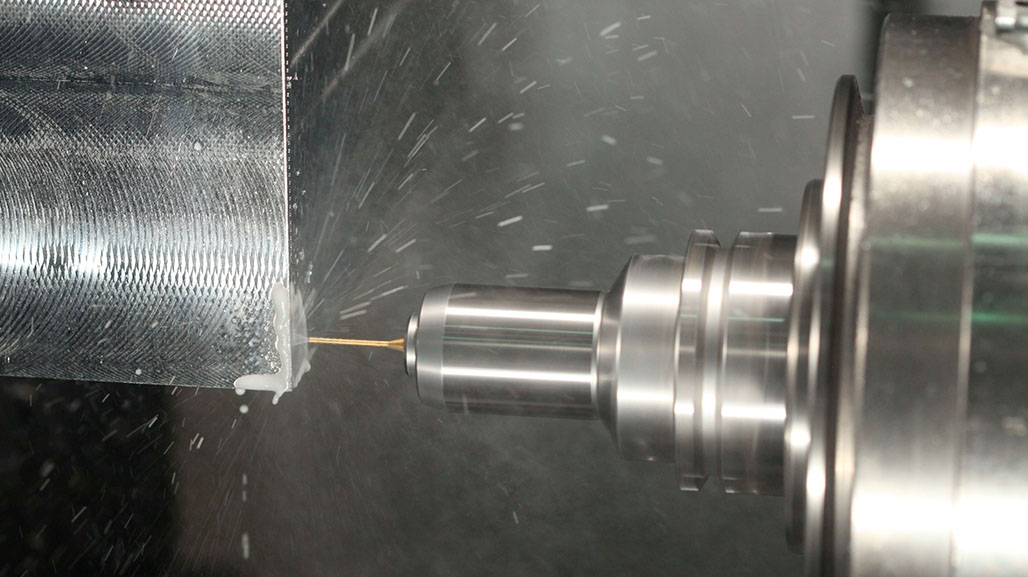

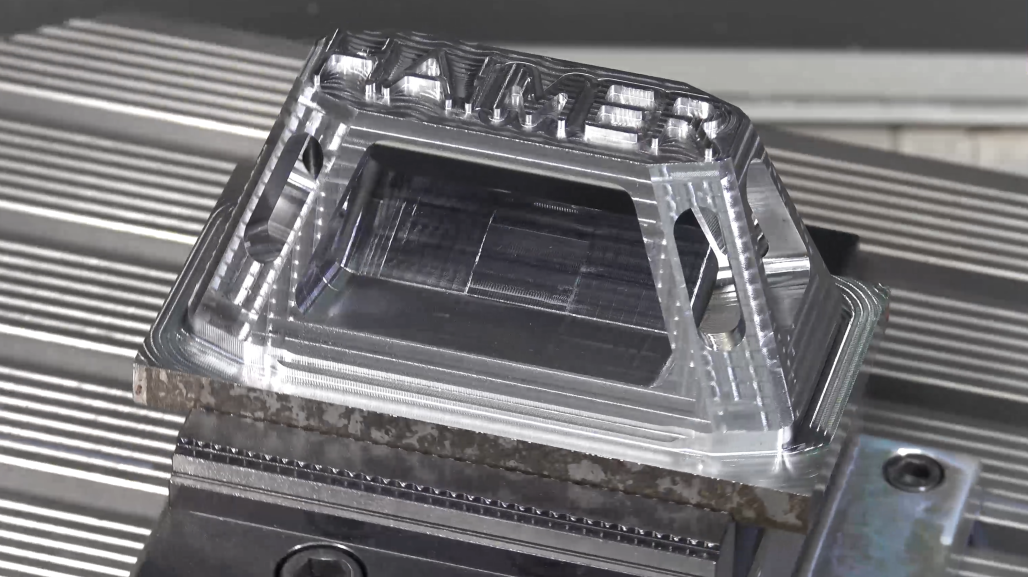

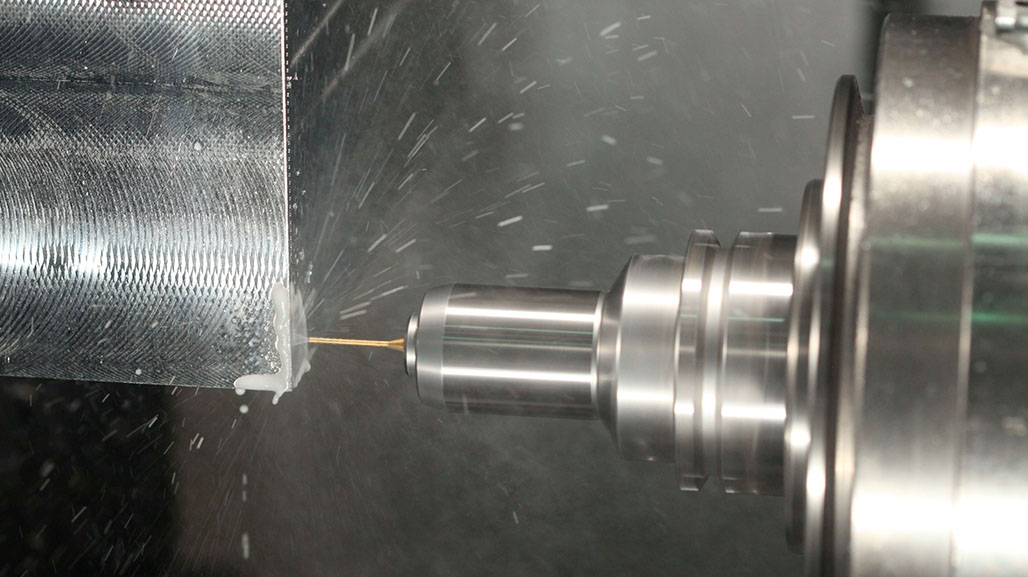

Learn what makes austenitic and PH stainless steels so difficult to drill and how you can improve tool life and productivity.

Discover expert insights, industry trends, how-tos, and product tips to boost efficiency, cut costs, and improve operations - all in one place.