What You Need to Know

We live in a world where our lives seem to revolve around the Internet.

The IoT is revolutionizing the way we live and do business.

Having the IoT connectivity on the shop floor can decrease downtime in 2 ways.

We live in a world where our lives seem to revolve around the internet. We can connect from nearly anywhere, depending on our device and internet availability.

And so many things are connected to the internet, from health insurance systems, to academic records, to home security systems. Connecting things – objects (like automobile sensors), people (like those with heart monitor implants), and animals (like microchips in house pets) – through sensors is how the Internet of Things (IoT) was created

The IoT is revolutionizing the way we live and do business.

These things each have a unique identifier and are able to transfer data via the internet without human interaction. When the low tire pressure indicator lights up on your car’s dashboard, it’s part of the IoT. The same is true when a lost dog’s owner is located via the microchip in the pet’s shoulder. When the grandfather with a pacemaker sends his heart monitor reading to the doctor’s office via his home device, it’s done through the IoT.

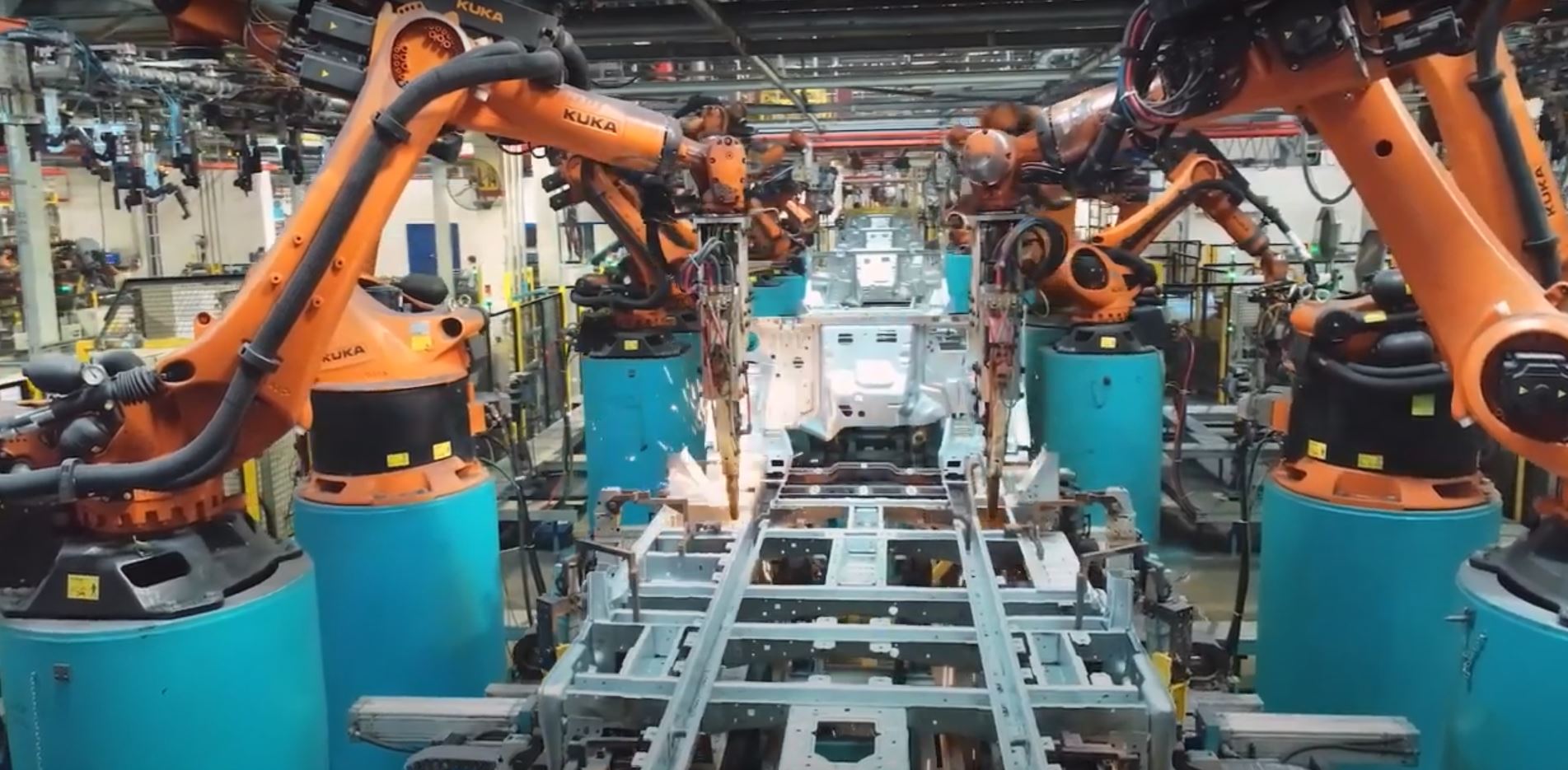

The IoT keeps things connected with very little human intervention needed. This type of interconnectivity is especially popular – and necessary — between machines in a manufacturing facility.

Streamlining Manufacturing

In a typical factory, employees are often the first line of defense to equipment problems. They spot potential equipment problems and alert a manager, who assesses the problem and assigns an owner to correct it. The process can take hours, days, or longer. It’s a very manual process that relies on human intervention.

Having the IoT connectivity on the shop floor can decrease downtime in 2 ways:

Sensors can alert employees to an equipment change that may not be visible. This early intervention can eliminate the potential problem before equipment fails.

Rules can be created to notify the appropriate person when a problem is detected. This eliminates the need for management to assess the problem and identify an owner. Imagine having a technician show up with the right tools and parts necessary for a service order, based solely on data streamed directly from the equipment itself, with no human intervention. This can drastically cut downtime and increase production. This type of efficiency is a big benefit to manufacturers.

Sharing Information in Real Time

In the past, data collection, analysis, synthesis, and reporting was done for days or weeks to obtain production information. In manufacturing, this often meant missing opportunities for process improvement while waiting for relevant data. The IoT enables real-time access to both data and information.

Every factory has manufacturing data challenges. The IoT is helping to bridge the gap between those challenges and efficient solutions.

Key Takeaways

The Internet of Things has a heavy influence on the world we live it today.

It has reshaped the way data is shared and transferred which revolutionizes the way we do business.

Manufacturers are now able to use the new found connectivity to help maximize productivity.

Previous featured on the Kennametal Chronicle.

Brought to you by Kennametal

Kennametal brings together materials science, technical expertise, innovation and superior customer service to help the world fly, drive, power and build. Our tools, materials and wear-resistant solutions enable customers to run longer, cut faster and machine with greater precision across various industries from aerospace and defense, general engineering and transportation, to earthworks and energy. We don’t just make products, we deliver solutions.

Related Articles

Smart Restrooms: Companies See Value in IoT Connected Dispensers

How the Manufacturing Rebound Will Change Employee Recruitment and Retention

VIDEO: Automated Manufacturing in CNC Machining Environments

Getting a Better Grip: How Workholding Tools Are Adapting to 21st Century Demands