Gold Isn’t Just for Looks

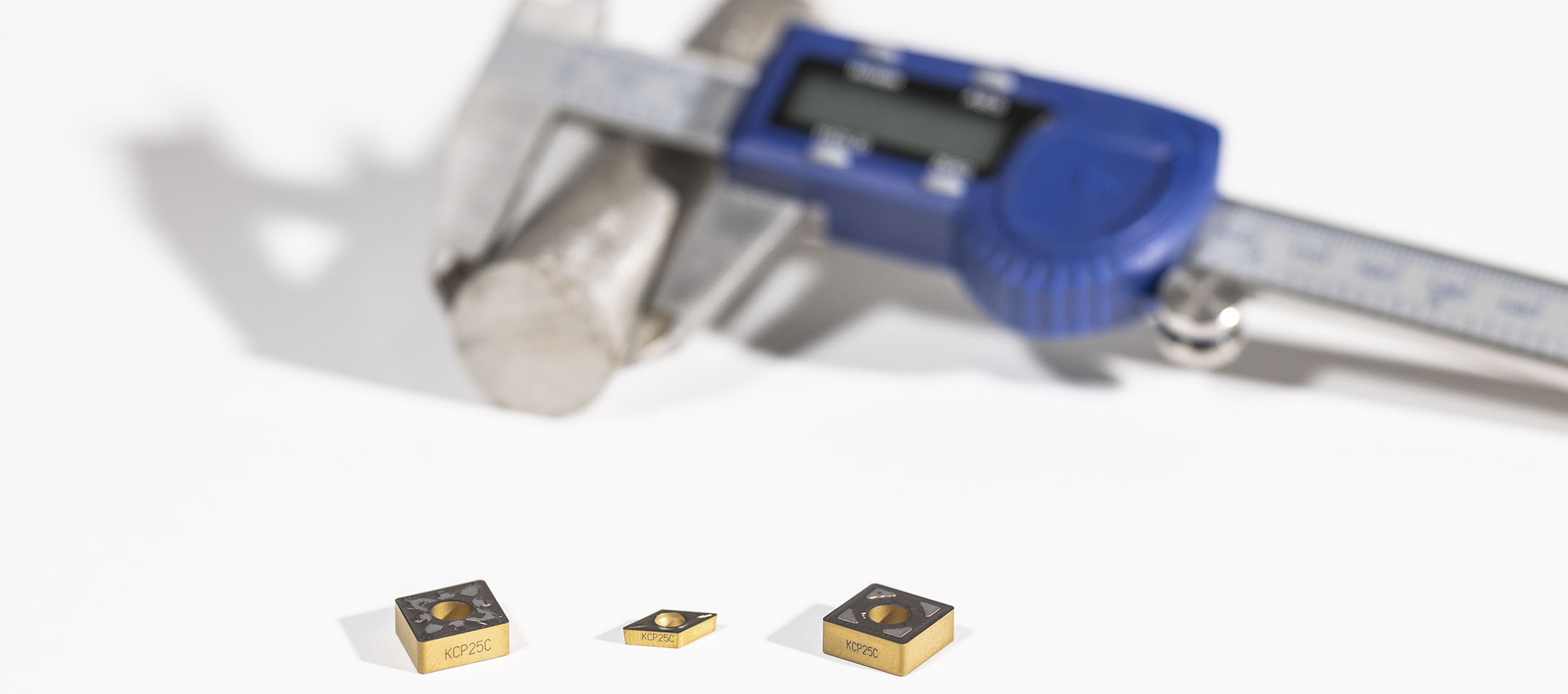

One of the standout features of Kennametal’s inserts is their distinctive gold coloring. While the gold hue might seem like a branding choice, it serves a much more practical purpose on the shop floor, according to Sage.

“With the two KCU grades, the entire insert is gold-colored, while with the KCP grade, just the sides of the insert are gold,” Sage says. The lighter gold coating makes it easier for operators to quickly see which edges of the insert still have wear life on them, helping to prevent premature disposal and maximize tool life.

Says Sage: “You can look at it, and you can say, ‘Oh, yeah, we haven’t run that edge yet. OK, let’s make sure and use that one.’ You’d be surprised how often you can go through a bucket of used inserts and find two or three corners that haven’t been used.”

Coming Soon: New Top Notch Grades

Sage says beginning in late 2025, the new grades will be launched in Kennametal’s Top NotchTM platform, which is used for shallow grooving operations such as cutting O-ring and snap ring grooves.

“Top Notch is a rectangular-shaped insert, and it has a notch that runs diagonally across the top of it, which is where the name comes from,” Sage says. “And what it provides is an extremely rigid style of insert. The way that it gets clamped into the pocket means that it’s held extremely tightly and is very rigid.”

Adds Sage: “Top Notch is an industry standard that is celebrating its 60th anniversary in 2025, and so it’s kind of cool to marry the legacy of that platform and how well it has worked for the last 60 years with these newest generations of grades. It’s really bringing this new technology to a proven legacy platform that has performed extremely well.”

The two KCU Top Notch grades are expected to launch in fall 2025, with the KCP Top Notch grade launch scheduled for spring 2026.

Global Giveaway

To celebrate the launch of these next-generation inserts, Kennametal is running a global giveaway featuring custom toolboxes filled with select Kennametal brand merchandise and bestselling turning products, including the new grades. The promotion is open for entries until the end of December, with winners to be announced by Jan. 15, 2026.

It’s all part of the company’s efforts to shine a brighter light on its turning products, Sage says. “We really want to focus on getting back to the core of our business and making sure that customers and suppliers know that Kennametal is still the turning company of choice to go with.”

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *