What You Need To Know

Learn the elements of a fully integrated digital “smart” factory.

Cloud software can combine tooling, documentation and purchasing options in one program.

For manufacturers who work with suppliers worldwide, it’s important to capture real-time data.

A look at the opportunities and benefits this technology provides.

The fourth industrial revolution, otherwise known as Industry 4.0, embraces manufacturers that are using advanced technologies to add connectivity, exchange data and introduce communication between machines and automation throughout the shop floor. It includes the industrial internet of things (IIoT) and cloud computing, both of which have the potential to move the industry forward by keeping the internal workforce, suppliers and distributors in constant collaboration.

With nothing to install, the ability to work together worldwide and the flexibility of a surplus of digital storage space, cloud computing lends to fulfilling a vision of a fully integrated digital “smart” factory. It deserves serious consideration from any manufacturer who sees the benefits in monitoring, tracking and managing data and products as a means of improving efficiency and quality while reducing costs. Software companies that provide applications for manufacturers are steadily developing upgrades and new cloud-based apps, tools and programs. Here’s a look at one company that recognizes the potential this service provides and a software leader helping to bring about change.

Transforming the Way You Work

Tooling manufacturer Kennametal Inc. offers a suite of cloud-based apps, called NOVO, to help customers improve their manufacturing production and workflow. “For NOVO, we wanted to allow as many as possible to access our data and expertise in a way which was easy and convenient,” says Mitch Benko, director of virtual machining at Kennametal. “We wanted something that was rather intuitive, so whether they’re an expert or a novice they can get into NOVO, find anything they need within the Kennametal portfolio and make use of it in their own systems.”

NOVO contains a digitized version of catalog data for its thousands of products, along with speeds and feeds and recommendations for improvements and optimized machining strategies based on rules, “tribal knowledge” and catalog footnotes, all collected in a cloud database.

To start planning a new manufacturing process with NOVO, customers select the material to be used or the specification to be met, along with the type, dimensions and other variables of the feature they want to machine. With its built-in intelligence, a “tool advisor” then presents strategies for creating that feature.

After selecting a strategy, NOVO searches the Kennametal catalog and provides ranked suggestions for a tooling sequence, along with the most productive tools to perform the sequence on that material. Individual jobs or tool lists can be saved for future use in cloud-based accounts and shared with both internal members and external partners of a team.

Building Virtual Models

The NOVO tool selector suggests only the tools that should be used together for any given machine. It can create a digital model of the tool assembly that can be printed out or downloaded, for example, to a computer-aided manufacturing (CAM) system or a Zoller tool presetter. This way, you can perform a simulation or program the tool paths needed to create the work piece before running it live.

“Not only can you make sure creating the work piece won’t crash the machine, but you’ll be able to test and ensure you’re creating a productive model,” says Benko.

All of NOVO’s capabilities are free, and if a customer wants to purchase tooling, the software includes an e-commerce section, which interfaces with purchasing departments and sales representatives.

“We want to make it easy for customers to execute business requirements in a self-sufficient environment,” says Benko. “NOVO supports this way of doing business by connecting those dots between tooling, software solutions, documentation and purchasing.”

Using Real-Time Data to Stay Competitive

Another cloud-based software system helping manufacturing companies improve their bottom lines is SynergySPC (statistical process control) by Zontec. Manufacturers can discover, analyze and minimize variations by using statistical methods that monitor and control a process. For example, metalworkers who use SPC software can eliminate manual data processes, reduce scrap and rework, minimize time-consuming tasks and gain access to real-time data.

SynergySPC integrates with production systems like gages, optical comparators, CMMs, PLCs, OPC servers, ERP software, LIMs, and SCADA, MES and CRM systems, and provides real-time reports to each level of user. The reports can be archived and emailed. Clients such as Trident Precision Manufacturing, which selected Zontec’s SynergySPC line because, according to Trident Director of Quality April Lusk, “they were one step ahead of where our customers were going,” have seen the advantages Synergy’s cloud-based apps bring to their businesses, including the ability to:

Instantly inform an operator when a machine or product is out of control or out of specification.

Report to customers when products are within the agreed-upon specifications.

Use precontrol limits during production to maximize tool wear while maintaining a good product.

Take on more business without losing efficiency in data collection.

While there are different versions of SynergySPC for the cloud for different needs, the Synergy 3000 software was designed specifically for global manufacturers that work with suppliers’ SPC data, want to use Windows networks, and use secure web connections and mobile devices in a cloud computing environment. The company’s Synergy 100 Cloud and Synergy 1000 Cloud can help smaller firms make the initial investment, allowing organizations with limited resources to use the muscle of SPC to revolutionize their businesses.

Enabling Industry 4.0

Cloud-based software programs like NOVO and Synergy are at the cutting edge of a rapid global advance toward Industry 4.0. By leveraging cloud software and infrastructure, Kennametal’s Benko has seen firsthand the advantage of machines sharing information among their shop floor systems and gaining a better understanding of how to improve productivity.

“Once you’ve digitized the product data, it leads to development of virtual tools and automation, which eventually evolves the future state of manufacturing,” says Benko. “You’re able to streamline reporting, improve efficiency or analyze customer behaviors, all of which will inevitably drive future investments.”

Key Takeaways

Develop a plan to achieve a fully integrated digital “smart” factory.

Kennametal’s cloud-based NOVO digital tools easily conform with inventory, e-commerce and other platforms to optimize productivity.

SynergySPC software in the cloud attracts customers by being accessible, adaptable and easy to use.

What cloud computing vendors and applications do you use in your shop?

Featured Manufacturing Abbreviations and Definitions of Terms

Cloud: Remote computing services such as software applications, data storage or website hosting. Widely known examples are Dropbox, Google Drive and Apple iCloud.

CMM: Coordinate measuring machine is used to measure physical geometrical characteristics of an object.

CRM: A customer relationship management system is a set of software applications that helps an organization determine the needs and preferences of its customers by managing, organizing, tracking and storing customer interactions.

ERP: Enterprise resource planning software helps companies integrate and manage many back-office functions such as finances, the supply chain, manufacturing operations and human resources.

Internet of things: The connection and networking of objects and data through the internet.

Industrial internet of things: The internet of things applied to manufacturing.

LIMs: Liquid injection molding is a complex production process employed when making rubber components or parts that must tolerate extreme conditions.

MES: A manufacturing execution system manages and monitors work on a factory floor.

OPC servers: Open-platform communication is an interface that allows Windows programs to communicate with industrial hardware.

PLC: Programmable logic controller is an industrial digital computer adapted for manufacturing, such as assembly lines or robotic devices.

SCADA: A supervisory control and data acquisition system collects data in real time from various locations to control equipment and conditions.

Related Articles

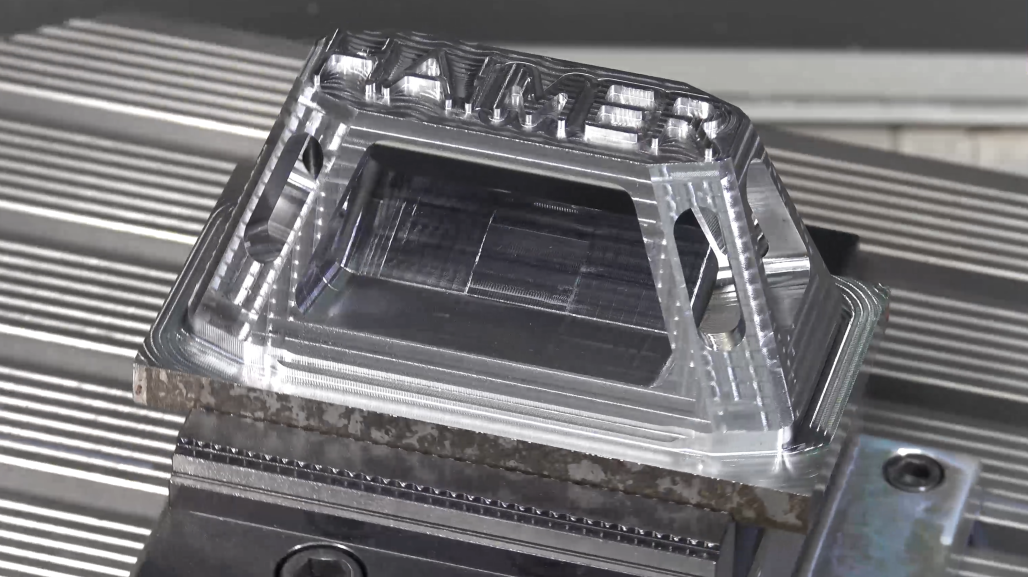

TOOLING UP: From Holder to Cutter: Inside HAIMER’s Full Tooling Assembly

Your Go-To End Mill for Price and Performance: GOmill™ PRO

Not Your Grandpa’s Welding PPE and Gear

Selecting the Best Welding and Cutting Equipment: What You Need to Know