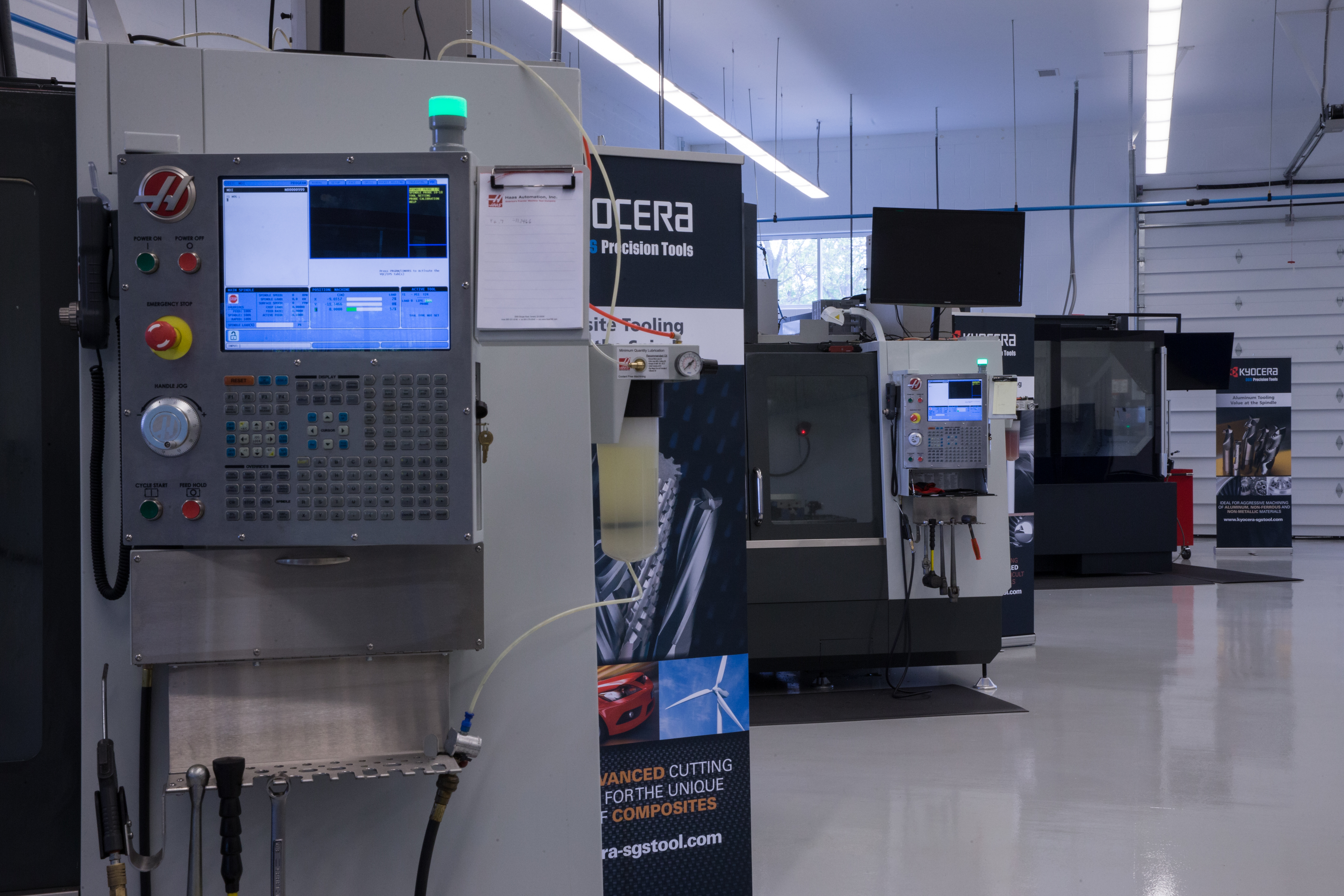

KYOCERA SGS Precision Tools, Inc., formerly known as the SGS Tool Company and a wholly-owned subsidiary of KYOCERA Corporation, was originally founded in 1951 and is an ISO-certified leader of round solid carbide cutting tool technology for the aerospace, metalworking, and automotive industries. Today, it is best known for its solid carbide high performance end mills and drills. However, it is also well known for its stainless steel medical tools and technically advanced, proprietary PVD coatings. KYOCERA SGS Precision Tools, with manufacturing sites in the United States and United Kingdom, aggressively services its customers through a global network of Sales Representatives, Industrial Distributors, and Agents that sell into more than 60 countries.

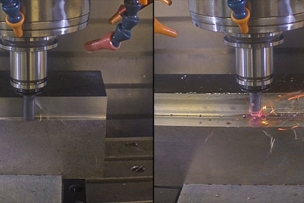

When using conventional end mills on stainless steel, the cutting teeth entering and exiting the material create a natural rhythm that results in one of the most damaging forms of cutter wear known as chatter. With its patented, one of a kind geometry, the Z-Carb AP offers three stages of chatter suppression, resulting in the quietest, most stable milling experience available.

Stainless steels, like 17-4Ph are one of the most commonly used materials in all the manufacturing industry. Its applications include aerospace, automotive and even the nuclear industry. In an annealed state, 17-4 stainless steel can be one of the nastiest materials to work with. It can get gummy and warp or twist if it has not been heat treated.

With conventional end mills, the cutting teeth entering and exiting the material creates a natural rhythm that results in damaging harmonics. Harmonics produce a frequency that resonates through the entire tool, resulting in one of the most damaging forms of cutter wear known as chatter. Chatter degrades the quality of your finish. Until now, your only choice was to adjust your operating parameters to account for the limitations of your conventional end mill. With its patented, one of a kind geometry, the Z-Carb AP offers three stages of chatter suppression, resulting in the quietest, most stable milling experience available. Watch the short video above to see it in action.

KYOCERA SGS Precision Tools (KSPT) actively maintains a serious commitment to research and development. Our reputation for quality and ever increasing Value at the Spindle® pushes us to continually innovate and discover the next best thing in cutting tool technology. The Z-Carb AP is a product of this passionate pursuit. Field testing demonstrates the KSPT design achieved higher material removal rates while meeting or exceeding expected tool life.

Brought To You By

More from KYOCERA SGS Precision Tools

More on Innovate

It’s been said that necessity is the mother of invention, but sometimes a more proactive and collaborative approach is required, especially when it comes to manufacturing innovation.

In this episode of MSC's Tooling Up, Toni Neary is joined by Brendt Holden, President of Haimer for a discussion on their innovations in shrink fit technology.

In this episode of MSC's Tooling Up, Toni Neary is joined by Jergens Vice President Matt Schron and Product Manager Mike Antos for a discussion on the 5CV Self-Centering Vise.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *