As a brand of Saint-Gobain, a world leader in sustainable habitat, Norton offers the widest portfolio of grinding, cutting, blending, finishing and polishing solutions for all markets, materials and applications with the most advanced and affordable technology. So, as your needs evolve, our access to the global expertise of Saint-Gobain becomes even more valuable to making a difference in your day-to-day needs. And, we don’t have to look far for more localized expertise with our largest research center located right nearby in Northboro, MA.

Unique Three-Pointed Curved Grain Approach Offers Advantages for Tough Grinding Applications

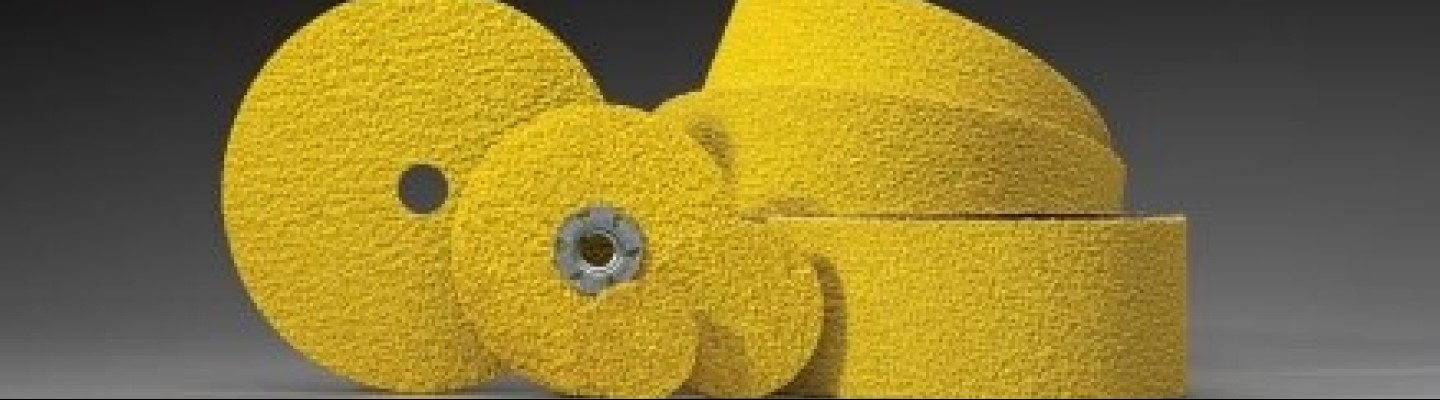

While creating a shaped grain may be nothing new in the world of abrasives, the optimum shape for that grain has been elusive until recently. A new three-pointed curved grain approach has shown impressive advantages including in tough grinding applications. This grain technology was unveiled by Norton | Saint-Gobain Abrasives as part of its RazorStar coated abrasive line that includes belts, fiber discs and quick-change discs.

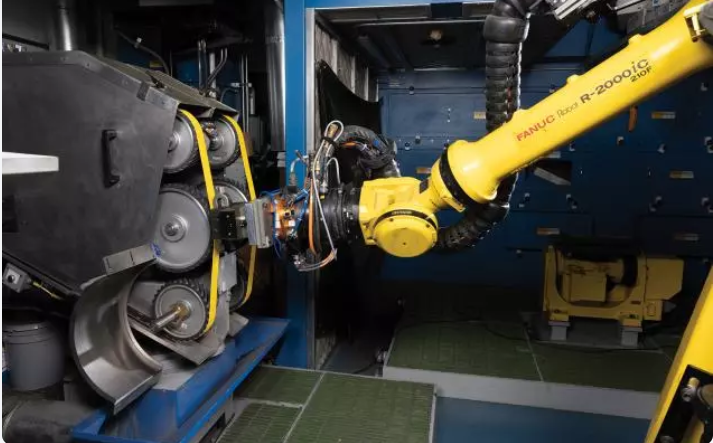

Combining razor-sharp grains along with a supersized grinding aid can help significantly reduce heat generation for cooler cuts and longer life on a range of materials such as carbon steel, aluminum, stainless steel, nickel alloys and other hard-to-grind metals.

Enabling exceptionally high cut rates and material removal, the engineered shaped grain in Norton RazorStar belts and discs features a consistent shape from grain-to-grain along with razor-sharp cutting points. For long, abrasives life, the patented geometry and tough micro-structure enable the grain to stay sharp, as new cutting points are exposed when the grain fractures. These abrasive products also feature a high concentration of grains that are oriented in an upright position, so the abrasives are ready to cut and aggressively perform at their sharpest point.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *