As a brand of Saint-Gobain, a world leader in sustainable habitat, Norton offers the widest portfolio of grinding, cutting, blending, finishing and polishing solutions for all markets, materials and applications with the most advanced and affordable technology. So, as your needs evolve, our access to the global expertise of Saint-Gobain becomes even more valuable to making a difference in your day-to-day needs. And, we don’t have to look far for more localized expertise with our largest research center located right nearby in Northboro, MA.

Because of its importance to the final finish, most abrasive manufacturers offer some type of anti-loading (or anti-clogging) solution. Norton | Saint-Gobain has engineered a design that uniquely marries grain structure and backing options with an environmentally friendly, proprietary stearate coating called No-Fil. This technology repels debris from the grain and is especially effective in diverse finishing tasks where material tends to stick to the abrasive (like paint removal or deburring metal).

The No-Fil stearate is manufactured in-house to a carefully regulated formula. Controlling the entire production process ensures the highest quality standards are met with every run. So, no matter where in the world you purchase or use your Norton abrasive, you will get the same high level of performance you need. Plus, our custom-formulated stearate is environmentally friendly in both how it is produced and how it can be disposed of after use. All the components are biodegradable, assuring the highest level of sustainability available in the market.

There are multiple advantages Norton’s No-Fil coating brings:

- Longer life – multiple studies over the years prove that a stearate-coated abrasive performs up to 50% longer. The result for you is fewer disc changes, less disruption to workflow, and better inventory efficiency.

- Consistency of finish – No-Fil abrasives are contaminant-free, helping you achieve the finish you want without causing damage to the surface of your workpiece. This is accomplished by keeping the abrasive viable longer without particulate interference.

- Less friction – the No-Fil coating provides a lubricating layer to reduce friction between the grain and the workpiece surface. For you, that means smoother operation, less heat generation, and a finer finish.

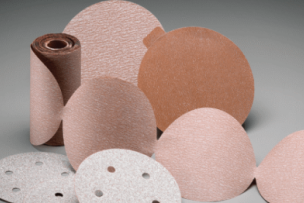

- Flexible options – No-Fil abrasives are available on paper, mesh, and film backings. And Norton's portfolio offers good-better-best alternatives to help you find the right product at the right price for the projects on your docket.

Performance to the Highest Standard

Norton’s No-Fil anti-loading technology is specifically designed to help you achieve the best results, no matter your application. But don’t take our word for it. The Norton brand has grown into a global leader in the abrasives market because customers just like you in markets from automotive and aerospace to manufacturing and do-it-yourself believe in the reliability and quality of their abrasive products.

“I have many customers that finish gelcoat and paint,” noted Austin Drake, Territory Manager, Marine Program Manager, Saint-Gobain. "Typically, I see a lot of waste when sanding on these materials due to other products loading up too quickly. The No-Fil line of products fixes this issue. My customers love that No-Fil lasts longer before loading and is easier to clean and reuse. It also provides them with a superior finish which makes the scratches much easier to buff out.”

Previously Featured on Norton Abrasives' Resources page.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *