ISCAR is the largest of the 15 companies comprising IMC (International Metalworking Companies). Together, they supply a dynamic comprehensive line of precision carbide metalworking tools. These companies produce a wide range of carbide inserts, carbide endmills, and cutting tools, covering most metal cutting applications. IMC also provides engineering and manufacturing solutions to major industries throughout the world. Many innovative products, designed especially for customer requirements, have made IMC a world leader in major manufacturing industries such as automotive, aerospace, and die & mold production.

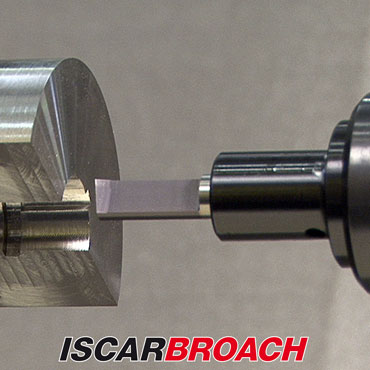

Broaching is an application used for precision machining of many industrial part types. The most common applications of broaching are keyways and splines. ISCAR engineers have developed a range of unique high precision tools for broaching applications of workpieces in small batches.

Keyway grooves

Machining keyway grooves is becoming more prevalent in general engineering and applications associated with industries such as automotive, heavy duty, gear, weapon and more. Keyway tool designs, when used with dedicated broaching machines, are designed for long production runs. The ISCARBROACH tools enable finishing a complete part which improves machining cycles and provides high quality solutions for small batches of parts.

ISCAR's broaching tools can broach blind or through holes applications. The traditional production of blind keyholes involves expensive die sink (EDM) operations. With relief grooves or cross holes, blind keyways can be broached on a CNC machining center with ISCAR’s broaching tools.

Beside solutions for machining the standard material groups, ISCAR’s broaching tool designs provide high accuracy and repeatability characteristics and allow keyway applications on difficult to machine materials such as titanium, Inconel and stainless steel.

Talk to Us!

We have a HAAS TM-2P, and want to broach a 1/4" key way in an aluminum part that is 1.0625"deep. We would like to know what tooling is recommended and parameters for programming.

115I’m looking to broach on CNC Okuma Crown Big Bore lathe . Width .189 +.003 / -.000 x 1.5 deep . It’s a thru hole

46I am looking for you catologe for you carbide inserted style holder and broaching tool. I do not see it on your website.

204we are presently using a Haas 90 degree broaching insert EDP#: 02-0885 MFR#:HIN-SQ-27/37

in Haas EDP#: 04-0821 MFR#:HSK63A-EM-1.25-4.33 holder.

My female part is 1.2839 major dia. x 1.193 minor dia. x 31 teeth

which yields an 88.3871 degrees.

My spline length is 2in long.

I would like to use the same type of indexable broaching system.

but with a 88.3871 degree angle on the insert.

can you please quote - holder, inserts & lead time

If you need drawings & cad models I would be happy to forward them.

Thanks

3Leave a reply

Your email address will not be published. Required fields are marked *