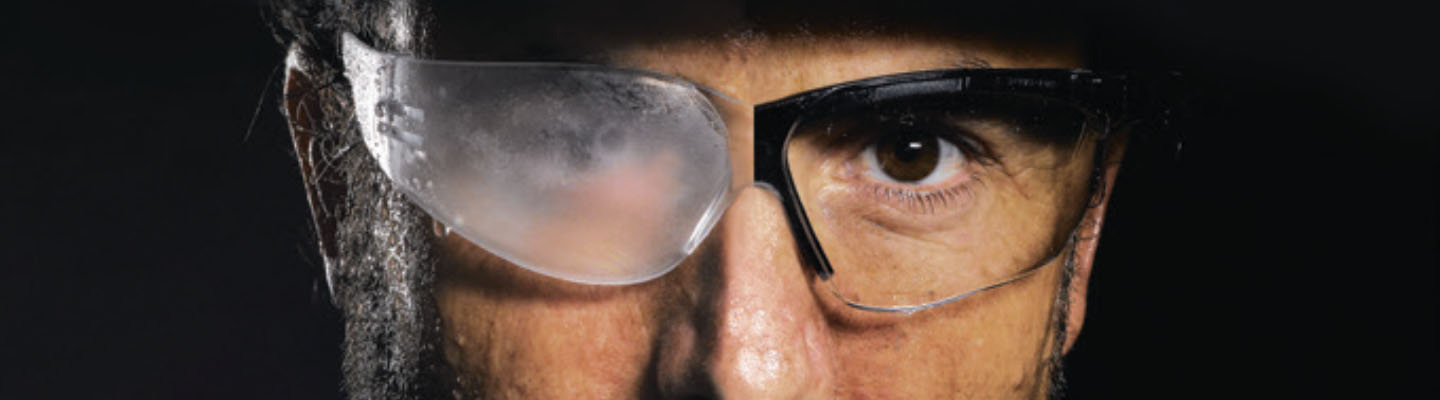

Fogging Eyewear Solutions

Eyewear manufacturers typically use one of two types of lens surfaces for getting rid of fogging:

- Hydrophilic surfaces work by absorbing moisture on the lens and distributing it evenly, essentially clearing the vision.

- Hydrophobic surfaces work by repelling moisture so it runs off and doesn’t cling to the lens.

Uvex by PIP’s patented innovation leverages both hydrophilic and hydrophobic anti-fog methods in its Uvex HydroShield® safety eyewear.

“We’re absorbing that moisture, and then the moisture is being pulled away from your vision and down to the outside of the lenses,” Perales says. “So, you will see moisture, but you’ll see it dripping from the outside of the lenses as it clears from your vision.”

Video: How to Fit and Wear Safety Glasses

HydroShield delivers at least 180 seconds of fog-free time, far surpassing the federal anti-fog standard of eight seconds.

The American National Standards Institute and the International Safety Equipment Association first included criteria for anti-fog PPE in their 2020 update of the eye and face protection standard (ANSI/ISEA Z87.1). Compliant products are marked with “Z87” along with “X” for anti-fog.

Benefits of Permanent Bonding During Manufacturing

The power of HydroShield’s anti-fog properties is in the manufacturing.

“Our anti-fog technology is permanently bonded to the lens and lasts the lifetime of the lens, so there is no need to reapply,” Perales says.

Permanent bonding helps HydroShield withstand harsh conditions and repetitive cleaning, leading to long-term fog protection. Plus, because workers aren’t having to frequently stop what they’re doing to readjust their glasses or reapply a coating, they are more comfortable and productive during their shifts. Employers also avoid extra costs for anti-fog supplies, such as application wipes.

Testing shows that HydroShield’s fog-free protection lasts 90 times longer than most other anti-fog products, dependent on the environment and application.

Anti-Scratch Coating with Anti-Fog Eyewear

Besides fogging, lens scratching is another challenge that employers must overcome. “Scratching is also a concern,” Perales says, “because once a glass becomes scratched, customers would tend to replace it.”

To address the issue, some eyewear manufacturers include anti-scratch coatings. With Uvex’s products, she says, “our anti-scratch coating is two times more effective.”

A Family of Anti-Fog Eyewear

It’s one thing to provide protective eyewear, and it’s another to ensure that people are actually wearing it. Employers would do well to have a variety of options to suit worker preferences for comfort and style while also ensuring compliance.

Fortunately, HydroShield’s anti-fog properties are available in Uvex Avatar™ Plus, a comprehensive family of safety eyewear that includes three styles.

Read more: See the Difference: Introducing Uvex Avatar™ Plus Protective Eyewear

“We call it a one-stop shop, because we offer safety spectacles, goggles and an over-the-glasses option—that pretty much covers most of what you need within your facility,” Perales explains.

The safety spectacles add versatility and comfort with a floating nose pad and flexible temple design, plus a variety of lenses available in different tints and coatings.

“If you choose a family like this, you give your employees options,” Perales says. “This allows them to select what works best for them, and it also allows the safety manager to know that everyone is in compliance.”

Another smart way the Avatar Plus line supports compliance is plain to see: All products have a subtle but unmistakable frame color.

“Citrus green is easy to spot,” Perales says. “The Avatar Plus family lets the safety manager look out through the facility and make sure that everyone’s wearing a safety glass that complies with the ANSI standards. That’s most important.”

What kind of eyewear fogging issues are you dealing with at your facility? Let us know in the comments.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *