Five Tips for Preventing Accidents with Flammable Safety Cans

It is important to follow safe practices when using a safety can. Here, Justrite brings you five tips to avoid potential accidents.

It is important to follow safe practices when using a safety can. Here, Justrite brings you five tips to avoid potential accidents.

Justrite flammable safety cans include many features to prevent fires or injuries when working with flammable liquids. Automatic positive pressure relief vents between 3 and 5 psi to relieve pressure and avoid an explosion. Flame arresters dissipate heat to stop flashback ignition. Type II safety cans include hoses to make it easy to pour into narrow openings, reducing the chance of spillage.

But even with all these features, it is still important to follow safe practices when using a safety can. Here are five tips to avoid accidents when using safety cans:

1. Never overfill your safety cans above their rated capacity, which is up to the seam where the can top meets the body of a metal safety can or at the fill level mark on plastic safety cans. In fact, most experts in the fuel industry agree that 90 percent capacity is the safe fill level. This amount allows room for expansion due to temperature changes. This practice will also help thwart spills and overflow, and prevent warping or distortion to the container.

RELATED ARTICLE: Flammable Liquid Storage Requirements for Safety Cans

2. Burp your safety can before use, especially in hot climates. High external temperatures cause a rise in pressure inside your flammable safety can. Even if the pressure isn’t high enough to activate the pressure relief vent, it may still cause a liquid splash when pouring gasoline. With the can in an upright position, open the fill cap briefly to relieve the buildup in pressure.

3. Use a bonding wire when pouring into or out of a flammable safety can. Bonding creates an electrical connection between the dispensing and receiving container, thus preventing a static charge buildup and possible spark.

RELATED ARTICLE: Never Do These Things When Pouring Gas

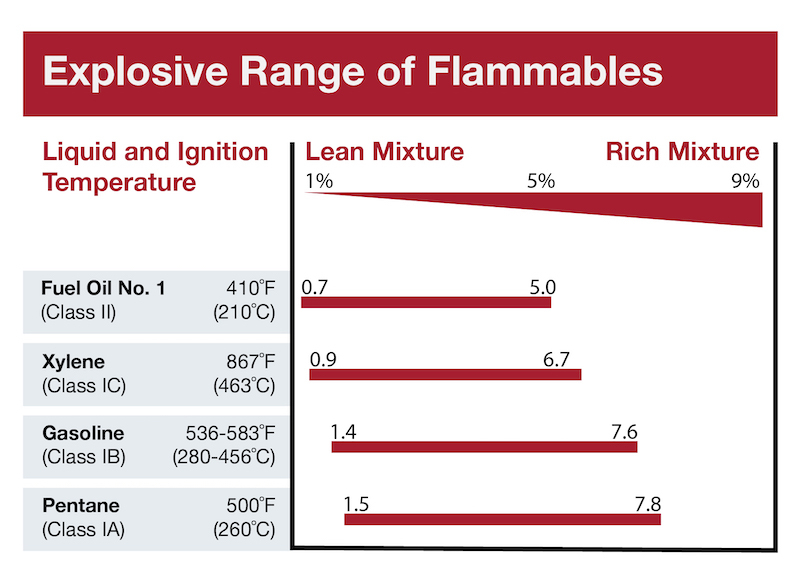

4. Never pour gasoline while working around a hot engine. The flammable/explosive range (the concentration ratio of a vapor that will burn or explode if an ignition source is introduced – see chart below) for gasoline is between 1.4 and 7.6 percent. Normal operating engine temperatures range from 195 to 220°F (91 to 104°C), though some internal combustion engines can get much hotter. Spilling even a few drops of gas onto a hot surface like a motor could cause an explosion.

5. Check the flame arrester on your safety can for damages. A puncture or tear in the flame arrester affects how it dissipates heat from a flame. It could result in ignition of the vapors inside the container. Replace a damaged flame arrester before using the safety can to prevent a fire or explosion.

As the safety industry’s leading manufacturer, Justrite helps their customers protect what matters most. Their high-quality Type I, Type II and DOT-approved flammable safety cans are made to work hard and built to last. Justrite safety cans meet OSHA and NFPA requirements. Most are approved by FM Global (FM) and/or Underwriters Laboratories (UL/ULC). Browse Justrite's range of safety cans here.

Previously Featured on Justrite's blog. Browse Justrite's solutions to protect workers and the environment on MSCDirect.com.

Since 1906 customers have relied on Justrite for solutions to protect workers and the environment, reduce fire risks, and improve productivity. Hazardous material storage and handling products comply with applicable OSHA, NFPA, and EPA requirements, and most have been tested and approved by FM Approvals.