With businesses spending more time cleaning and disinfecting their facilities amid the ongoing COVID-19 crisis, selecting the right personal protective equipment (PPE) to sufficiently reduce exposure to chemical and biological hazards is essential. Here’s how DuPont™ SafeSPEC™ helps you select the best protection for your workers.

Imagine you are a manufacturing facility manager wondering how to safely clean and disinfect your workplace to prevent the spread of the coronavirus.

You’ve likely consulted the latest guidance for cleaning and disinfecting facilities from the Centers for Disease Control and Prevention (CDC), and you’ve probably established a routine for disinfecting frequently touched objects and surfaces such as bathroom doors, desks or computer keyboards with an Environmental Protection Agency (EPA)-registered disinfectant that kills human coronaviruses.

But what level of personal protective equipment (PPE) is required for these chemicals, and how should the PPE be used safely?

It’s a pressing question for workplaces in the manufacturing sector, which will be vastly different places for the foreseeable future as the COVID-19 pandemic lingers and companies adjust to a new normal.

Job one for employers is, of course, keeping workers safe. This involves revising office layouts, ensuring safe employee distancing and the frequent cleaning and disinfecting of everything that may harbor the coronavirus, from CNC machines to door handles.

Read more: First Aid: The Training and Supplies Your Company Needs

PPE is the last line of defense for those disinfecting a facility. But it’s not enough to simply purchase protective gowns, gloves and face masks. Employees should know the appropriate PPE to wear for each task and know how to don, doff and appropriately discard it.

Selecting the Appropriate PPE

DuPont SafeSPEC is an interactive tool that helps companies make informed decisions about PPE and other protective garments to use when cleaning a facility and handling various chemicals.

The site provides information about the company’s complete range of protective garments and accessories that address a broad range of PPE needs, including the Tyvek®, Tychem®, Kevlar® and Nomex® protection product brands.

Users can search for the appropriate protective garments by inputting various hazard scenarios to yield the best match for their task, from protective coveralls to glove and sleeve protection, helping to reduce contamination of workers’ skin and clothing by potentially infectious pathogens.

A user can enter from one to five chemicals or other hazards that may be present in a working environment, and the tool will find products that provide protection against the combined hazards.

The site allows users to search by hazard, industry or pre-saved scenarios or use a guide to find their particular chemical mixture or scenario. SafeSPEC even auto-fills complex chemical names to help users locate results quickly and easily.

For example, if a user were to submit disinfecting a room with a possible “bloodborne pathogen” as a hazard, that user may receive as a PPE suggestion a DuPont Tychem 4000 coverall, which features a standard fit hood, elastic wrists and attached socks. A “double-check” feature allows the user to tell if the product is suitable for a particular hazard (a chemical used for cleaning, for example), or a link to a “technical data sheet” that gives more detailed information about the product.

A user may also receive other PPE suggestions. DuPont Tychem nitrile gloves NT430, NT470and NT480 meet the EN ISO 374 standard for viral protection. They also provide over eight hours of protection against many common EPA-registered disinfectants, including bleach solutions, hydrogen peroxide and citric acid.

Assessing Your Workplace Risks

Before using the DuPont SafeSPEC tool, you’ll want to first identify the hazards you will face at your worksite and do a full risk assessment, which will include considerations such as workplace layout. Some workplace hazards may require more than one piece of PPE, such as working with a chemical like chlorine that irritates both the respiratory system and the eyes, requiring respiratory, skin and eye protection.

Next, look at the protective qualities of the PPE you’ll use, in particular, three elements: the fabric, seam and design. What are the best fabric options available to you? From DuPont, you’ll choose from Tyvek, Tychem and ProShield®—each with varying degrees of protection.

In making your determination, you should consider how long the chemical you’ll use could be sitting on the garment and the level of liquid penetration you may need. You’ll also want to look at the design of the garment and consider how long you’ll be exposed to a particular hazard. Do you need an attached hood or integrated socks?

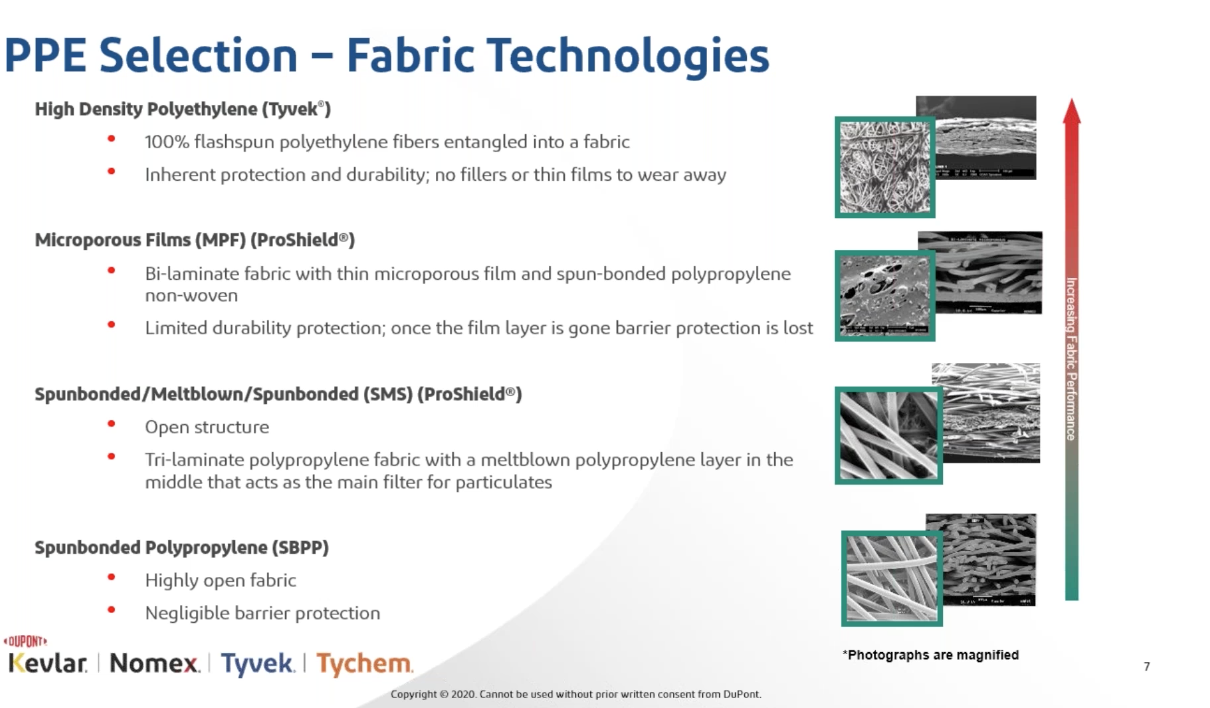

There are various fabric technologies for PPE on the market. The main ones are shown below:

Source: DuPont

These fabrics vary in their resistance to liquids and durability. Tyvek, for example, is made of 100 percent high-density polyethylene fibers, which provides inherent protection and durability. Spun-bonded polypropylene, by contrast, is a highly permeable fabric with negligible barrier protection.

Hand protection is another very important component of PPE. No one glove will provide protection for every type of hazard, so it’s important to know the hazard you will be facing in order to find the best protection.

Most gloves are designed for a specific hazard or task. Gloves used for protection against chemicals are not always good for protection against cuts, and vice versa. And matching your gloves with the appropriate garments is also important.

The DuPont Tychem glove portfolio includes offerings that protect a user’s hands against a wide range of highly concentrated chemicals, both organic and inorganic, as well as the biological risks posed by industrial products such as those found in the oil and gas, chemistry and environmental cleaning sectors.

Read more: Flammability Limits: How to Reduce Fire Hazard Risks in Your Facility

The New Role of PPE in Workplaces

One of the most common hazards facing workers is in their company’s cleaning supplies. Many commercial-grade cleaners contain carcinogens and substances that can damage the skin. Now that companies are cleaning and disinfecting more regularly, employees are at a greater risk of injury or illness.

The selection and use of PPE for cleaning therefore require careful consideration. There are many different kinds available that reduce the risk of injury when a worker is in contact with a hazard. Incorrect use of PPE, or buying inappropriate PPE, can lead to serious workplace incidents. And using PPE that is uncomfortable or restrictive can lead to secondary hazards.

Federal and state safety guidelines in response to the COVID-19 pandemic require more employees than ever to use PPE in the workplace, and so employers should ensure that workers fully understand the best practices for “donning and doffing” (putting on and taking off) protective equipment (see sidebar for more on this).

Those workers who regularly wore PPE and other safety equipment are now wearing additional equipment, and workers who never wore safety equipment at all are now wearing it, sometimes daily.

PPE is critical to maintaining protection in workplaces. Wearing it is important when handling chemicals, but also important given the contagious nature of COVID-19.

How to Correctly Don and Doff PPE

Protective clothing is designed to shield workers from physical, chemical or biological hazards. But the protection is not guaranteed by simply wearing the PPE. The correct selection, donning and doffing (putting on and taking off) of the clothing is a vital element of maintaining protection.

DuPont recently held a webinar where it described the correct steps for using PPE (in this case using a Tyvek coverall). Here are the most important steps to remember when donning and doffing your PPE:

Donning procedures for a Tyvek coverall:

Start the process by sitting down on a chair.

First, put on the protective foot covers.

Next, pull on the Tyvek coverall, starting with the legs.

Put on your first layer of protective gloves.

Pull the top half of the coverall.

If needed, use tape to close up the storm flap on the front of the garment.

Put on the outer gloves.

Put on any respiratory or eye protection needed (a respirator, face mask, goggles or safety glasses).

Doffing procedures:

When doffing PPE, it’s important to do so in a way that ensures your skin or clothing does not come into contact with the potentially contaminated outside part of the coverall.

First, remove the outer gloves.

Unzip the front of the garment, carefully rolling down so the outer side surfaces do not touch skin or clothing. Use gloved hands to pull down the sleeves and remove the arm portions, and continue to roll the garment down so the outside of the garment does not touch clothing or skin.

Next, sit on a chair and remove the rest of the coverall over the boot covers.

Remove the foot protectors, rolling them down so they do not contact clothing or skin.

Remove the gloves, turning them inside out as you remove them.

Related Articles

![Why the Cheapest Safety Gloves Aren’t Always the Smartest [Infographic]](https://images.ctfassets.net/5j4ln2up7bt7/2gVEyRZylkBIlvTDtTRRc7/dde0c00e4846d6a88d56a7a68f09332a/mcr-PD5931_action4571-thumb.jpg)

Why the Cheapest Safety Gloves Aren’t Always the Smartest [Infographic]

NFPA 30 and Safe Storage of Flammable Liquids

Why Mental Health Belongs in Every Safety Conversation

A Practical Guide to Using Folding Utility Trays in Maintenance Work