For more than 50 years, DuPont Personal Protection (DPP) has been creating groundbreaking solutions that protect industrial professionals around the globe. DPP brings together some of the most trusted names in personal protective equipment (PPE)—Tyvek®, Tychem®, Nomex® and Kevlar®—to provide unparalleled solutions that protect workers against chemical, thermal, electric arc, mechanical and other workplace hazards.

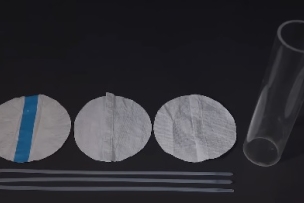

The bubbler kit puts microporous film (MPF) and DuPont's Tyvek® through a breathability and abrasion test.

DuPont™ Tyvek® demonstrates superior breathability and abrasion resistance when compared to MPF using a bubbler kit test. The bubbler kit test shows that Tyvek® allows air to flow through the fabric, and even maintains protective performance after abrasion. Comparatively, the MPF fabric is demonstrably less breathable than Tyvek®, and less durable than Tyvek® after abrasion. In the short video above, Dan Bowen, Technical Specialist at DuPont Personal Protection, breaks down the breathability and abrasion resistance difference between MPF and Tyvek®.

Previously Featured on DuPont's YouTube channel.

Brought To You By

More from DuPont

More on Personal Protective Equipment

The wide variety of choices in leather work gloves means that there is almost always “the perfect” one for any given application. Finding that glove, however, may not always seem so easy.

MSA V-Gard H2™ Safety Helmets feature ANSI Type II certification with the option of the Mips® brain protection system for industrial safety helmets.

Learn the differences between evaporative and moisture-wicking fabrics to help curb the dangers of heat stress.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *