Advances in smart technology are changing all aspects of manufacturing, including safety processes such as machine guarding.

OSHA’s annual list of most-cited violations can help companies in general industry avoid becoming a costly citation statistic.

There’s a lot more to fall protection than falls from great heights—especially in general industry.

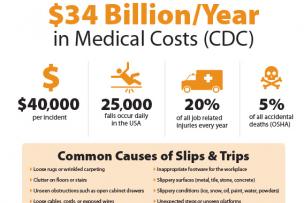

Work-related falls account for $34 billion a year in medical costs according to the CDC. Use this infographic to learn more about the common causes of slips and trips, and how to reduce the risk of them.

When more than one employee is involved in a lockout or tagout process, a special energy isolation plan is needed.

Fatigue can have a big impact on safety at manufacturing facilities. Learn how aviation FRMS practices can help reduce employee accidents.

Microlearning breaks topics down into bite-sized pieces, allowing workers to learn safety tips or refresh their knowledge without taking big chunks out of the day.

Dropped objects can cause injuries and damage equipment. The use of tool tethers is now being recognized as a best practice in a variety of industries.

Brady offers a variety of signs, tapes, labels and lockout products to help you operate more efficiently while at the same time creating a safer workplace. They have compiled a handy checklist to help you find out if your facility is properly identified.

Stay compliant and keep people safe both inside and outside your facility by promoting a safe workplace environment with safety signs.