Which HAIMER Balancing Machine is Right for Your Production?

HAIMER details the key characteristics of each of their balancing machines to help operators select the right one.

HAIMER details the key characteristics of each of their balancing machines to help operators select the right one.

As you might have read in a previous blog article called, “Unbalance: The Hidden Problem Machine Shops Need to Solve”, running an unbalanced tool assembly in the machine tool can greatly impact a machinist’s efficiency and work piece surface quality. After recognizing the importance of implementing balancing in a machine shop’s production, some may become overwhelmed with how many model variations of machines HAIMER offers.

To help operators select the right HAIMER balancing machine, below are the key characteristics between each of the models.

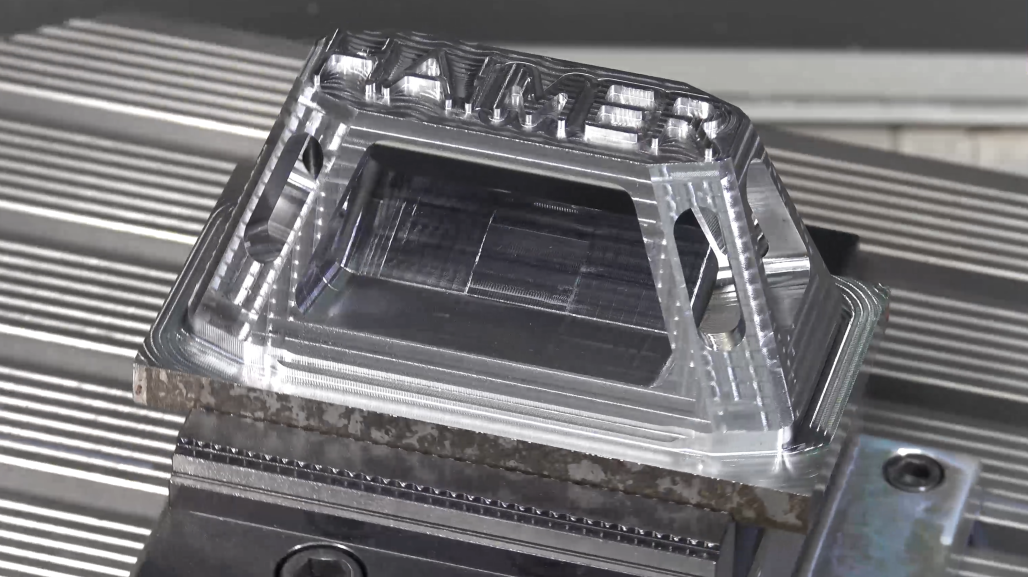

Tool Dynamic TD 1002 – For minimalists

The Tool Dynamic TD 1002 balancing machine is a solid, cost-effective, accurate way to start balancing complete tool assemblies in your shop. Designed to come standard with a proven table, this machine is the ideal solution for mold makers, small batch lots, single applications, grinding wheel arbors, and standard chucks. The Tool Dynamic TD 1002 measures and compensates the unbalance in one plane (static and standard) or two planes (optional). Therefore, it is perfect for balancing short tool holders and tools since in those cases, the couple unbalance is very low. The device operates via the integrated keyboard and screen.

Tool Dynamic TD Economic – For beginners

The Tool Dynamic Economic balancing machine is your introduction into the modular balancing system of the Tool Dynamic series. The one-piece design, with the solid 1,200 lbs. cast base, serves as a perfect foundation for accurate measurements. With the couple unbalance being very low on short tool holders, the TD Economic measures and compensates the unbalance in one plane (static), making it perfect for balancing short tool holders and tools. Of course, two plane balancing is an option for this machine and can be added at any time. Easy handling with an integrated keyboard and screen. Conveniently, there is also an option to connect a monitor, mouse and keyboard to this model.

Tool Dynamic TD Economic Plus – For the advanced

The TD Economic Plus is perfect to measure the unbalance in two planes (dynamic), again starting with the 1,200 lbs. case base. Long tools requires balancing in two planes to correct dynamic unbalance. With the laser indication, the optical indexing help and the automatic indexing of the spindle, balancing is very easy, quick and error free. The “fixed components” also allow balancing with screws for tools with threaded bores. The drawer allows easy storage for accessories. Easy handling with an integrated keyboard and screen. Conveniently, there is also an option to connect a monitor, mouse and keyboard to this model.

Tool Dynamic TD Comfort – For the ambitious

The most popular and recommended machine HAIMER USA sells is the Tool Dynamic TD Comfort because of its ease of use and most importantly, its accuracy. If you want to balance frequently and keep the balancing time as short as possible, you should decide on the Tool Dynamic TD Comfort machine. It is equipped with a PC, keyboard, mouse and monitor. The big screen enables you a fast input of tool data and all the comfort of a graphical user interface. This machine comes standard with the ability to balance in one or two planes. In addition, the software of the machine offers the possibility to correct the unbalance with the help of a milling program what is very common in practice to correct the unbalance.

Tool Dynamic TD Comfort Plus – For perfectionists

The Tool Dynamic TD Comfort Plus offers a maximum level of usability and comfort. Using the TD Comfort Plus you will never lose sight of your goal during the balancing progress. Would you like to balance your tools efficiently, fast and without being an expert? The Tool Dynamic TD Comfort Plus is a great option because it has optimized touchscreen usage, integrated PC, comfortable storage for your balancing accessories, all within the machine's “Tool Control” making balancing fast, convenient and very easy.

Tool Dynamic TD Preset Microset – For individualists

The Tool Dynamic Preset Microset is a perfect combination of HAIMER´s balancing and HAIMER´s Microset presetting technology. The high-precision balancing spindle fitted with HAIMER´s proven adapter system clamps the tool. This saves time and increases accuracy because the tool does not have to be re-clamped.

Tool Dynamic TD 800 – For specialists

Based on the proven Tool Dynamic balancing technology, the Tool Dynamic TD 800 allows balancing big rotors of all kinds (up to 800 mm). Bearing rings, grinding wheels and turbine wheels. With hand-tailored clamping adapters you can balance your rotors as easy and quick as usual. The segmented safety hood of the TD 800 allows it to open on the sides. Thus, the part to be balanced is accessible from above, which allows a crane to lift heavy parts into the machine.

Tool Dynamic TD Automatic – For individualists

The Tool Dynamic TD Automatic is a truly universal CNC-based balancing machine with automated correction of the unbalance. It automatically compensates the unbalance in one or two planes by drilling or milling. The machine can make the correction vertically and horizontally. The balancing machine has an integrated 19’’ touchscreen and the numerical control is a Siemens 840DSL, which is accessible simultaneously with the balancing software.

Previously Featured on HAIMER's blog.

Haimer is a globally recognized leader in premium tooling technology, specializing in solutions, mainly for the metalworking industry. As a German manufacturer, Haimer is dedicated to delivering exceptional quality across its product range, which includes shrink fit tool holders, collet chucks, shrink fit machines, carbide end mills, balancing machines, tool presetters, and 3D sensors. At Haimer, quality is the cornerstone of success: QualityWins.