It takes a lot to get it right. To be a company that lasts more than 100 years by continually evolving and growing to meet the needs of our markets and customers. Our first-to-the-market and best-in-the-market approach led us to receive hundreds of patents over the years and truly shape an industry. We do what others don't in ways they can't. We offer innovative products backed by years of research and development. Beyond our quality products and reliable solutions, we add value for our customers through strong partnerships and a commitment to solving important problems. Brady offers solutions to help increase safety, security, productivity and performance throughout your facility—everything from printing systems, software and high-performance labels to facility signs, safety devices, expert safety services and more.

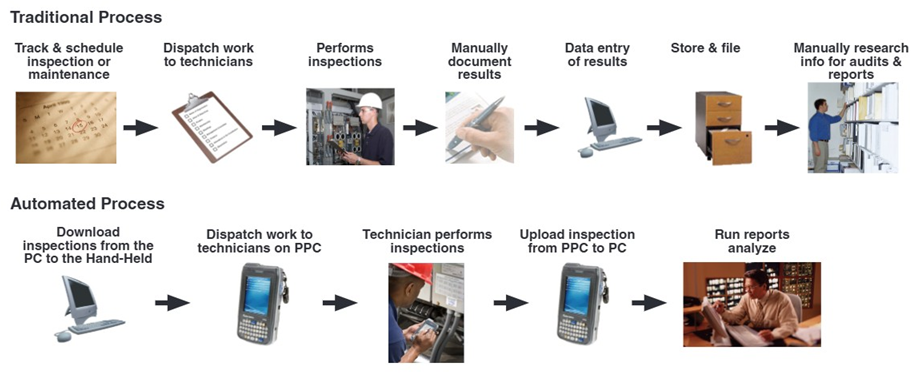

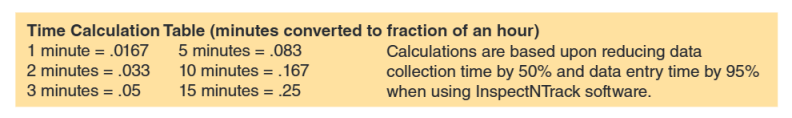

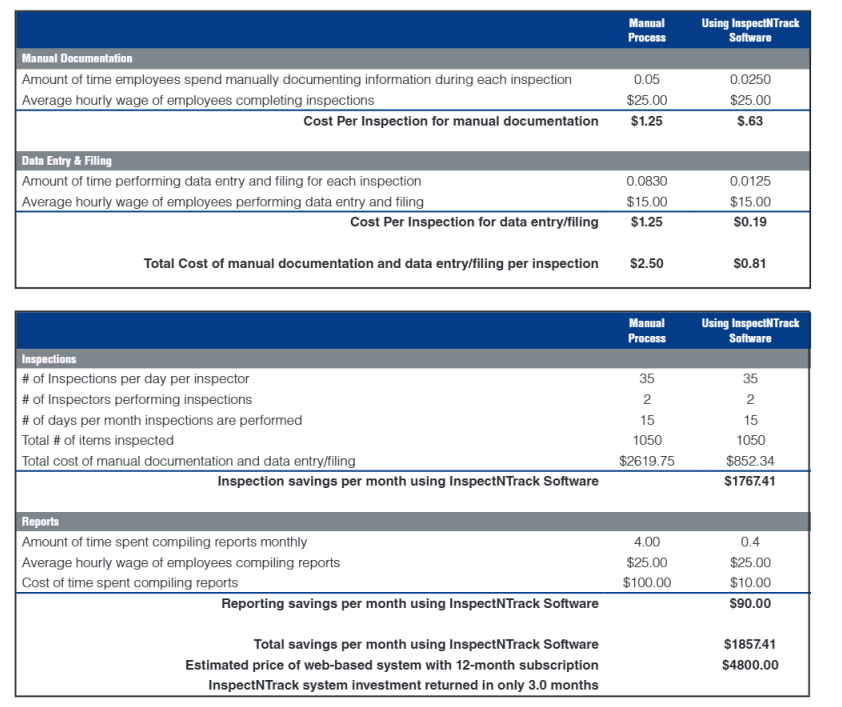

This article focuses on web-based software that is used to schedule, track, and document equipment, location, and safety inspections. The software replaces manual, paper-based procedures with automated data collection solutions. This type of solution is most commonly used to assist companies in reducing expenses by establishing a regular routine for preventive maintenance checks. It also assists in complying with mandatory workplace safety regulations that ensure a secure physical environment.

Initiating a successful facility inspection process can be a daunting task. Based on the amount of equipment requiring inspection, the upfront effort in gathering data can be a time consuming undertaking.

A thorough process involves:

• Compiling a list of all equipment requiring inspection and documenting the inspection intervals for each.

• Verifying the location of equipment.

• Planning a logical inspection route that incorporates all equipment locations.

• Setting up a method for tracking inspection dates to ensure that inspections are not missed.

• Setting up a method for tracking discrepancies to ensure corrective action is taken.

Although initially time consuming, it is well worth the time invested to emerge with a process that is consistent, repeatable, and straightforward.

SCHEDULING,TRACKING, AND DOCUMENTING INSPECTIONS

Traditional facility and safety inspection processes are heavily paper-based. Automating the process can save time and money while increasing productivity, efficiency, and equipment life.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *