The catalog of TRIM® cutting fluids excels at extending sump life, improving efficiency, and reducing consumption. This creates sizable cost savings, even in shop environments that have already maximized efficiency.

One customer, a mid-size manufacturer specializing in precision aerospace parts, had created a cost-effective production system and was satisfied with their existing fluids. However, a short-term test of TRIM uncovered a massive reduction in overall costs.

THE CHALLENGE

After a thorough plant survey, Master Fluid Solutions®, working alongside the customer, identified several production issues and areas of improvement. Many machines created excessive foam, causing coolant to spill on the floor and requiring frequent maintenance. This wasted valuable fluid and created hazardous working conditions.

The customer purchased expensive defoaming additives to curtail the problem, but they were not always effective and drove up operating costs. Another issue required additional spending on hazardous biocides to keep bacteria and fungal growth in check.

THE SOLUTION

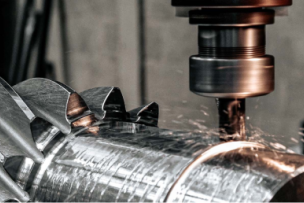

Master Fluid Solutions recommended TRIM® MicroSol® 585XT, a semisynthetic microemulsion that offers superior foam control and excellent sump life properties. The fluid performs exceptionally well with titanium alloys and mixed metal environments, making it an ideal solution for aerospace manufacturers. The product lasts substantially longer than most other fluids on the market, without additional biocides or defoaming agents.

THE RESULTS

MicroSol 585XT eliminated the foam and coolant spill issues without extra defoaming additives. With fungal and bacterial growth under control, it drastically reduced odors in the shop environment. The greatest change, however, came from the new solution's cost savings.

The metalworking fluid spend for the previous coolant was $140,250 per year, with $11,250 in taxes and $11,060 in freight costs, drastically exceeding the customer's budget. What's more, the defoaming additives cost $4,080 per year, bringing the grand total of fluid costs to $166,640 per year.

By purchasing MicroSol through a local stocking distributor with less lead times and delivery costs, improving their process, and using a more efficient coolant, the customer reduced coolant spend nearly $40,000, or 24%.

Master Fluid Solutions continues to provide superior coolant monitoring services to find more opportunities for cost savings and improved efficiency.

THE NUMBERS

- Eliminated the need and cost of defoaming additives

- Reduced logistic and tax costs by $22,310

- Reduced total cutting fluid costs by almost $40,000, equivalent to 24%

Previously Featured on Master Fluid Solutions' Case Studies.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *