An increase in production orders for new breeds of high-volume and high-value automotive components required OMG to consider alternative approaches to part inspection. Investments in off-machine gauging and on-machine probing enabled the company to increase manufacturing throughput, avoid rejects and reduce scrap.

Background

Established in 1949, OMG s.r.l Officine Meccaniche (OMG) manufactures high-tech mechanical parts and sub-assemblies for cars, vans, trucks and tractors. A third-generation business, the company has evolved rapidly, from simple sheet metal forming and tube bending to complex aluminum and cast-iron machining.

Its extensive manufacturing capabilities span a complete range of automotive component requirements, including engine blocks, cylinder heads and suspension assemblies. OMG's customers are worldwide, and it operates technology-leading factories in Turin (Italy), Valladolid (Spain) and Kaniow (Poland).

Central to OMG's success is maintaining close partnerships with its customers. The company is quick to adapt existing production lines to meet specific requirements, from adding new machinery, to setting up new systems and working closely with customers in product design and prototyping to develop an effective manufacturing solution.

Quality, of course, is an essential cornerstone of the OMG business. Long before the advent of global quality standards, the company had created its own methods, checks and documentation to ensure tolerance compliance and manufacturing consistency. Today the company is certified to the required ISO automotive and environmental standards.

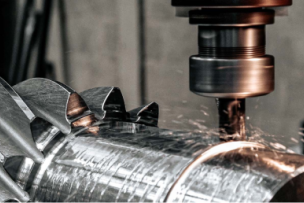

The company offers latest generation 4- and 5-axis CNC machining, state-of-the-art robotic handling, extensive automation and is already geared up to meet the demands of Industry 4.0.

For many years Renishaw has played an important role as a technology partner to OMG, as Guido Mautino, Chief Operating Officer of OMG explains. "Our partnership with Renishaw began in the mid-1990s when we started machining our first engine heads. We needed to take precision measurements directly on the machining centres, so we turned to Renishaw for advice."

"Today we have 23 machining centres fitted with a range of Renishaw machine tool probes. Over the years, this has put us in a position to engage with a variety of global product markets where high-precision measurement during production is a pre-requisite. All our CMMs are fitted with Renishaw PH10 motorized indexing heads."

Challenges

With forward-thinking new clients and next generation automotive product developments come new demands for process control solutions. Here, Renishaw considers two technical challenges where OMG had to find a completely new approach to part measurement.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *