Better MRO's Top 10 Stories of 2022

Take a look back as we round up Better MRO’s top manufacturing, metalworking and safety content in 2022.

Take a look back as we round up Better MRO’s top manufacturing, metalworking and safety content in 2022.

In 2022, manufacturers had to grapple with ongoing supply chain issues, labor shortages, and an uncertain economic environment. In addition, inflation pressures impacted purchasing decisions for some shops – whether to upgrade equipment or buy less expensive tools.

The adoption of digital manufacturing techniques continues to gain traction and there has never been a more opportune time to embrace the smart factory. With the Great Resignation following a global pandemic adding to the labor shortage, automation can fill in the gaps.

In compiling this year's top 10 most viewed articles on Better MRO, we see an interest in attracting and retaining skilled workers, seeking out tips to machine difficult materials, cutting tools that offer versatility and increased tool life, and the rationale behind not buying cheap cutting tools. Readers were also interested in government compliance under the Trade Agreements Act (TAA) and safety topics such as OSHA reporting on high-risk workplace injuries.

We hope you like our list. Let us know what other topics you enjoyed or if there are any other themes you’d like us to cover in the comments below.

Now, here is our list of the year’s most popular content.

No. 10: Why You Need to Stop Buying Cheap Cutting Tools

Everyone wants a good deal. That’s just as true when shopping for cars and groceries as it is when buying cutting tools. But just like cheap imported sedans and generic hot dogs, you don’t always get what you bargain for with low-cost drills, end mills and carbide inserts.

Many cheaper tools don’t use the finest materials available or the best hard coating technology, leaving them prone to wear and damage.

If your shop cares about maximizing productivity and achieving consistently high part quality, hear from the experts on why spending a bit more for your cutting tools typically yields a significant return on investment.

Read more: Why You Need to Stop Buying Cheap Cutting Tools

No. 9: 7 Strategies of Great Safety Managers

The effectiveness of workplace safety programs can be measured in dollars and cents as well as employee injuries and, in some cases, lives. The federal Bureau of Labor Statistics recorded 2.7 million workplace injuries along with 4,764 deaths in 2020, the most recent year for which data was available.

So what management tactics support a successful workplace safety program? They range from listening to workers on the front line to learning the hazards inherent in the company’s operations, setting a clear vision for organizational safety and visibly following its guidelines.

This article elaborates on 7 key recommendations from safety professionals you can put into place at your facility to drive a successful safety culture, along with sources of additional information.

Read more: 7 Strategies of Great Safety Managers

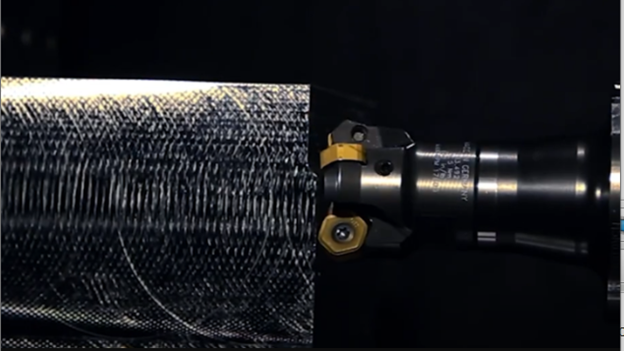

No. 8: VIDEO – New Accupro VS Plunge Mill

There was certainly no shortage of new product innovations in 2022. Traditionally, plunge milling has been done with indexable tooling on CNC machines, but the Accupro plunge mill offers a cost-effective solution to the user. The unique design solves for the traditional weakness of plunging with an end mill.

The Accupro VS Plunge Mill offers the unique combination of a variable helix end mill with the added capability of drilling. The special end gashing and face design permit drilling and aggressive ramping angles.

Click on the link below to see it in action.

Watch now: VIDEO – New Accupro VS Plunge Mill

No. 7: Machining Superalloys: Experts Offer Tips for Hard-to-Cut Materials

Superalloys are metals that are notoriously hard to machine but common in the aerospace, energy and medical industries. Inconel ranks among the least machinable of all metal alloys. All are challenging to machine, requiring rigid equipment and cutting tools designed for these demanding materials.

Good news, though – there are plenty of cutting tools to choose from.

Hear from three cutting tool manufacturers who offer end mills, drills and turning inserts designed specifically for these challenging materials.

Read more: Machining Superalloys: Experts Offer Tips for Hard-to-Cut Materials

No. 6: Managing the Supply Chain Crisis: How Manufacturers Can Navigate the Shortages

As supply chain woes continue to plague many companies, compounded by a backlog at the nation’s ports, a lack of shipping containers and recent severe weather events, manufacturers are looking to boost their supply chains to guard against future disruptions.

Considering the total cost of ownership is one way. “Don’t sweat the small stuff,” says Rebecca Jasper, director of global supply chain at Minnesota Rubber and Plastics. Look at the total cost of ownership and determine if a price increase is a fight worth having, she adds.

Click on the link below for more helpful tips.

Read more: Managing the Supply Chain Crisis: How Manufacturers Can Navigate the Shortages

No. 5: VIDEO: TOOLING UP – Extreme Versatility with the Kennametal Dodeka Mini Milling Cutter

In this MSC Tooling Up video, Kennametal introduces the newest addition to its Dodeka line, the small but mighty Dodeka Mini. It can run in many materials with the same cutter body…just swap out the insert!

12 cutting edges per insert offer ample flexibility. You can run your tool longer without stopping to change inserts and 25% lower cutting forces mean longer tool life.

Watch the video now to see how you can turn your spindle into a one-stop shop with the Dodeka Mini from Kennametal.

Watch now: VIDEO: TOOLING UP – Extreme Versatility with the Kennametal Dodeka Mini Milling Cutter

No. 4: OSHA Seeks More Details on High-Risk Workplace Injuries

The U.S. Occupational Safety and Health Administration (OSHA) is proposing a rule that would require U.S. employers in higher-risk industries including metalworking and machining to submit more detailed digital records on workplace injuries and illness, some of which it would post online.

“These narratives could be used by workers, along with injury rate statistics, to better understand how to spot hazards at work,” an official at the National Institute for Occupational Safety and Health said. “They could also be used by managers or worker organizations to help teach workers how injuries occur and how they can be prevented.”

While the ultimate goal is to focus resources on those workplaces where workers are at high risk, there are some potential drawbacks. Requiring covered employers to submit case-specific data can put a strain on small and independent businesses that cannot afford the experts, accountants, and lawyers needed to comply.

Learn more about the pros and cons of this proposed rule by visiting the link below.

Read more: OSHA Seeks More Details on High-Risk Workplace Injuries

No. 3: VIDEO – How to Drill Stainless Steel: 6 Tips

Due to machinability variations from one alloy to the next, it can be challenging to determine the optimal feeds and speeds during holemaking operations. This is true for any material group, but even more so for stainless steels.

Click on the link below and watch the short video to get some great tips and guidance for drilling stainless steel, one of the more challenging metal groups used widely in medical, aerospace and general engineering applications.

Watch now: VIDEO – How to Drill Stainless Steel: 6 Tips

No. 2: 3 Keys to Attracting and Retaining Skilled Workers

According to a 2021 report from the National Association of Manufacturers (NAM), 77 percent of manufacturers say they will have ongoing difficulties in attracting and retaining workers for the foreseeable future.

In this article you’ll find out the steps three very different manufacturing companies have taken that have proven lucrative from their inception. You may also be surprised by the common theme that all three share.

Read more: 3 Keys to Attracting and Retaining Skilled Workers

No. 1: What is TAA Compliance? 5 Things You Should Know

Our most popular article of 2022 likely resonated with suppliers to the aerospace or aviation industries, who are probably familiar with the Trade Agreements Act (TAA). The legislation approves and implements the trade agreements negotiated between the United States and other countries under the Trade Act of 1974. Staying compliant and understanding all the rules and regulations can be challenging.

We’ll break down some key points you need to know to learn all the ins and outs of becoming TAA compliant.

Read more: What is TAA Compliance? 5 Things You Should Know

Editor’s note: To produce our list of top 10 articles, we analyzed the visits and engagement on all the content we published on the Better MRO site in 2022 to identify the most-visited items, excluding any content that was published in prior years (but updated for 2022).

Let us know your views on the stories and topics you found most useful in 2022—whether it’s related to one of our stories above or didn’t make this year’s list.