VIDEO: How to Drill Stainless Steel: 6 Tips

Watch this video for some great tips and guidance on drilling stainless steel, one of the more challenging metal groups used widely in medical, aerospace and general engineering applications.

Watch this video for some great tips and guidance on drilling stainless steel, one of the more challenging metal groups used widely in medical, aerospace and general engineering applications.

Due to machinability variations from one alloy to the next, it can be challenging to determine the optimal feeds and speeds during holemaking operations. This is true for any material group, but even more so for stainless steels.

Watch the video above for some great tips and guidance for drilling stainless steel, one of the more challenging metal groups used widely in medical, aerospace and general engineering applications.

For more information on drilling stainless steel, read: Machining Metals: 6 Tips for Drilling Stainless Steel.

Eddie: Hey everybody, this is Eddie with MSC and today we're going to give you six tips on how to more effectively and efficiently drill into one of the industry's toughest materials, stainless steel. I'm joined here by MSC expert machinist Aaron who's going to give us a couple industry leading tips. Aaron, what do you have for us?

Aaron: Yeah, so stainless steel is widely used in a lot of different industries, you know, such as aerospace, medical, general engineering, so it's very important that we understand the different applications that we're going to see throughout these industries and understand how to tackle these applications in the best way possible. So let's get started.

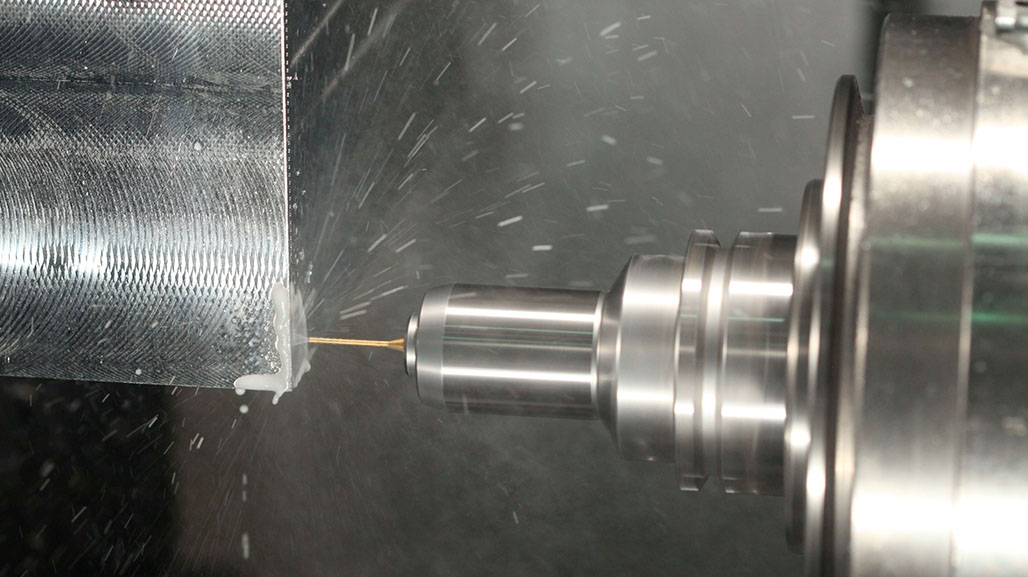

So the first tip we're going to talk about is going for solid carbide drills. Stainless steel generates a lot of heat so it's important to have a tool that can handle this type of temperature. Luckily, solid carbide drills are not only heat resistant, but they are also harder and stronger than your high speed or cobalt style drills. This, in combination with running coolant through the tool, will also allow you to push the tool much faster and more aggressively. In turn, this will facilitate a more efficient process for you. Don't forget that it's also important to consider your setup parameters. Rigidity of your workholding is vital for optimal output and increased tool life.

The second tip that we're going to talk about is pushing harder. When most machinists would typically dial back, we would suggest the opposite in most circumstances. So stainless steels typically have a high tensile and a high yield strength so if you aren't able to reach the minimum threshold feed per revolution, you won't have the desired penetration rate needed to achieve the desired cut that you're looking for. Even in the event that you have good coolant flow through the tool, you may unintentionally create a work hardened surface which only makes your job more difficult and as a general recommendation we advise starting slightly lower than the recommended cutting speed in combination with a fairly aggressive feed rate.

Tip number three is being specific. Stainless steel can often be gummy or sticky. When this happens it can lead to a buildup edge on the drill. This buildup edge will eventually break away but when it does, it's going to take some of the carbide away with it. In tandem with proper coolant supply and pressure, choosing the right drill for your work piece is nothing short of critical. You'll want to look for a sharper cutting edge and a light hone. Combining the right flute profile, point geometry, and heat-reducing coating will facilitate chip evacuation for a better overall end product.

Tip number four is gripping right. In a world of work holding, your choices range from mechanical to shrink fit or even ER collets. Though hydraulic holders are widely popular, ER collets also work just fine for smaller diameter drills but when you're using ER collets, it's very important to not overtighten them as they can create issues with concentricity. A torque wrench is typically suggested to help avoiding this mistake. Also make sure to follow the manufacturer's recommendations since they do vary from one to the other.

Tip number five is controlling the chips. With stainless steels, chips can commonly be long or stringy which can be dangerous. If an operator fails to control the chip creation and evacuation, they can very well be faced with unnecessary downtime as a result of jammed workspaces, broken machines, or bad cuts. Because shops tend to use general purpose drills for this application, this can be a big struggle at the spindle. This can force operators to peck drill which results in work hardening and decreased tool life. If your tool is specifically made for stainless, you have a greater chance of getting your chips managed properly, and though various forms of stainless steel require their own specific parameters, controlling the chips is vital to the success of your efforts.

Tip number six is do the math. It's no secret that carbide typically holds a higher cost. This can mean a lot to production workplaces with high mix, low volume, but in comparison to high-speed steel carbide almost always produces a lower cost per part which is just as important as the initial cost of the tool. Being stuck on the upfront cost can sometimes limit operators from seeing the benefit of using carbide. Greater productivity, increased tool life, and overall strength are all just key items to consider as you compare tooling in your search for the best tool for your application.

Eddie: Well, there you have it. Six tips on how you can more effectively and efficiently drill into stainless steel.