Techniks: Toolholder Maintenance

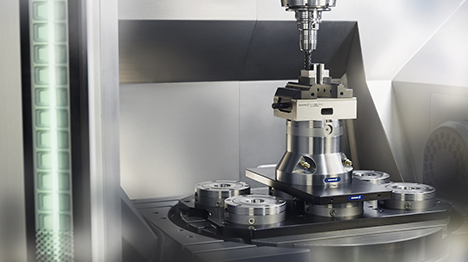

Toolholders are the most important connection between the machine and cutting tool. High-quality toolholders can extend tool life and save you money.

Toolholders are the most important connection between the machine and cutting tool. High-quality toolholders can extend tool life and save you money.

Toolholders are the MOST IMPORTANT CONNECTION between the machine and cutting tool. High-quality toolholders can extend tool life and save you money on perishable tooling.

A machine is only as good as its weakest link. With proper toolholder maintenance, along with timely collet and pull stud replacement, you can ensure low T.I.R. and extend tool life.

The chart below shows the relative impact runout has on tool life. The TIR% (Total Indicated Runout) is a % of the recommended chip load per tooth.

Overall cleanliness of your toolholder, collet pocket, collet, and nut must be maintained. All of these components are manufactured to perform within tolerances of ten-thousandths of an inch (.0001”). Any dirt, dust, oil, chips, or other contaminant left on the spindle, taper, flange, collet, collet pocket, or nut can cause poor T.I.R. leading to premature wear.

Techniks recommends regular preventative maintenance be implemented to protect your tooling and prevent scraps.

The best defense against unwanted wear is to properly set up your toolholder.

• Make sure to use the proper pull stud (retention knob) and tighten with a torque wrench to prevent overtightening, which causes swelling of the pull stud and bulging of the toolholder. • Place the collet in the nut prior to threading the nut onto the toolholder. DO NOT place the collet directly in the pocket. • Make sure the shank of the cutting tool extends to the bottom of the collet. • Use a torque wrench and tightening stand to ensure the nut is tightened to the proper specification following the torque chart (page 5). • Use indicator arm to check toolholder concentricity.

HOW DO I KNOW WHEN TO REPLACE COLLETS?

Collets are designed to wear out as they lose accuracy and rigidity with use. High side-load forces during milling operations cause cutting tool deflection as illustrated below. Over time, these side-load forces will bell-mouth the collet at its face.

HOW TO CARE FOR AND MAINTAIN COLLETS?

Collets are tools that are subject to wear, corrosion, and abrasion over a period of time. Gradual damage and wear can lead to loss of accuracy and functioning and may result in poor quality or interruption in your CNC machining operations. Therefore, it’s critical to maintain and take proper care of collets to ensure their longevity and optimum performance. Here are some pointers on caring for collets:

• Perform regular cleanings • Keep collets free from any debris or obstructions • Inspect collets for wear and tear

WHEN TO REPLACE?

It is recommended to change collets out every 4-6 months, depending on usage, to ensure the most rigid and accurate collet chuck assembly.

EVALUATING TOOLHOLDERS FOR WEAR

A worn-out holder will not provide good accuracy and will quickly wear out your cutting tools. Worn tooling causes poor surface finish, and may damage your spindle.

TAPER WEAR / FRETTING

Check the taper for signs of wear or damage where it contacts the spindle mouth. Any problems with the taper will have a direct effect on machining accuracy. If there are any imperfections on the taper, the toolholder should not be used.

PULL STUD REPLACEMENT

The pull stud is a critical safety component because it maintains the connection between the spindle and the toolholder. If that connection fails, the holder will dangerously fly out of the spindle.

Check the pull studs periodically for signs of wear, cracks, or other damage, and replace any that are not perfect or a dangerous situation may result.

The proper setup equipment from Techniks will ensure your tooling performs to its full potential.

Click here for a downloadable PDF of the Techniks Toolholder Maintenance Guide.