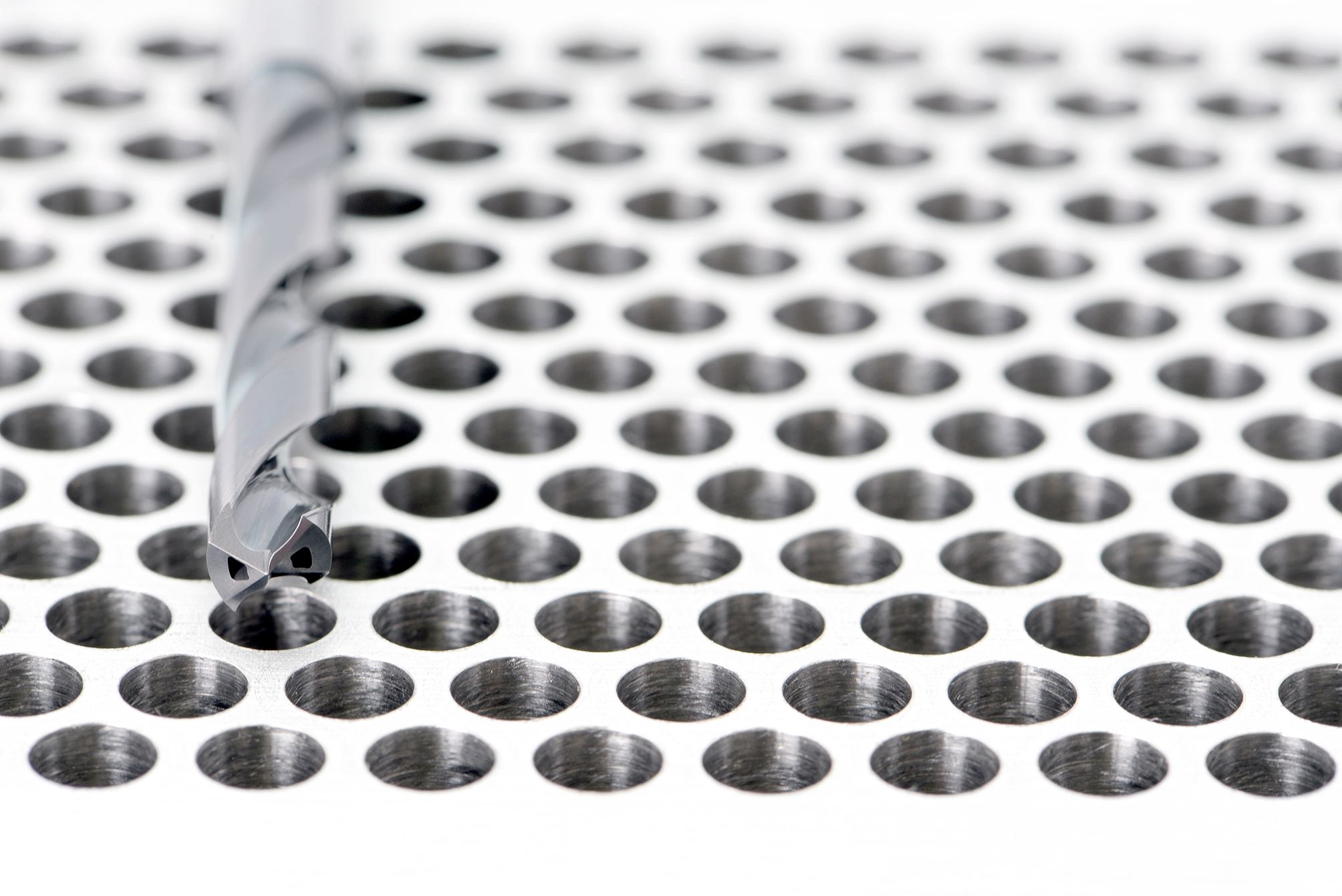

Machining Metals: 6 Tips for Drilling Stainless Steel

Learn tips for drilling stainless steel, one of the more challenging metal groups.

Learn tips for drilling stainless steel, one of the more challenging metal groups.

Every machinist should know how to work with various materials, but there’s always room for improvement. Here are some tips and guidance for drilling one of the more challenging metal groups, stainless steel, used widely in medical, aerospace and general engineering applications.

Due to machinability variations from one alloy to the next, it can be challenging to determine the optimal feeds and speeds during holemaking operations. This is true for any material group, but even more so for stainless steels. That’s because there’s a world of difference between drilling holes in 303 and 304 stainless, especially when additives such as selenium (303SE) or copper (304Cu) enter the equation, making both of these stainless steel alloys much easier to cut.

Similar examples exist elsewhere within the stainless steel family. For instance, 416 stainless is far more machinable than 440C, particularly when the latter is in the hardened state (such as drilling holes in rocks). And even though the precipitation hardening (PH) alloys such as 13-8 PH and 15-5 PH fall under the same umbrella as other stainless steels, they boast machinability ratings comparable to some superalloys.

Metallurgists will explain that such differences are due to the various grain structures and chemical compositions within this broad material family. They’ll point to chromium and nickel contents—two key determinants of machinability—and talk about the four classes of stainless steel, namely austenitic, ferritic, martensitic and duplex, all of which bear distinct physical properties and machining characteristics.

And although this might all be interesting from a technical perspective, it carries little weight to someone asking the basic question: What’s the best drill for this stainless steel part I’m working on, and how fast should I run it?

Steve George has some suggestions. The senior manager of global product engineering at Kennametal says productive hole drilling starts with the correct tool.

“Stainless steels generate a lot of heat, and solid carbide drills are not only more heat-resistant than high-speed steel [HSS] and cobalt but are also harder and stronger,” George says.

“That, and they’re usually equipped with coolant through the tool,” he continues. “Because of this, you can push them faster and more aggressively, leading to a more efficient process and ultimately, higher profits per part. However, the setup parameters must support it. Shops using less than rigid workholding, worn or improperly maintained toolholders, and older, slower machine tools might be better off with HSS.”

Read more: Industry 4.0 Technologies: Tips for Developing Your Digital Strategy

Keith Hoover, regional product manager at Kennametal, adds that the alloying elements in stainless steel make it far more susceptible to work hardening.

“Stainless steels boast relatively high tensile and yield strength, so if you don’t reach a certain feed per rev, you won’t have the penetration rate necessary to generate a proper chip,” Hoover says. “Even with good coolant flow, you might inadvertently create a work-hardened surface and have a hard time pushing through. That’s why, depending on the type of stainless steel, I generally suggest starting at the lower end of the recommended cutting speed range and use a fairly aggressive feed rate.”

Brandon Hull is in full agreement on through-the-tool coolant. The vice president of product management and business development at Guhring Inc. notes that stainless steels are typically gummy and sticky. This can lead to a built-up edge on the drill that will eventually break away, usually taking some of the carbide with it. Aside from using an adequate coolant supply—preferably under high pressure—the selection of a drill designed for the specific workpiece material is critical.

“Typically, you’re looking for a sharper cutting edge and a relatively light hone,” he says. “Together with the right flute profile and point geometry and a coating that reduces heat and promotes chip evacuation, carbide drills are a must for higher-volume applications.”

Hull wades into the yearslong hydraulic versus mechanical versus shrink-fit toolholding debate by stating that all of these are perfectly acceptable for hanging on to a carbide drill, provided the holder is high quality and well maintained. He also suggests that there’s nothing wrong with a good ER collet.

“I usually recommend hydraulic holders, but ER is fine for smaller-diameter drills—say, anything three-eighths of an inch and smaller,” he says. “However, I know that people tend to overtighten them, and that creates concentricity issues. Always use a torque wrench, and always follow the manufacturer’s recommendations, because they vary from manufacturer to manufacturer.”

OSG Tool regional applications engineer Daniel Dominski offers similar advice on all fronts. He also points out something that applies to most stainless steels: The chips are long, stringy and dangerous, and if you don’t get them under control, you’ll face unnecessary downtime due to jammed workspaces and broken machines or personal injury from cuts.

“That’s one of the biggest struggles with stainless, and it’s usually because the shop is using a general-purpose drill,” Dominski says. “They’re then forced to peck, but this leads to work hardening and poor tool life. If they use a drill made specifically for stainless, though, they have a much better chance of getting those chips curled up nice and tight. Of course, for the really gummy materials, like 304L, they might also have to drop their cutting speeds or bump up the feed rate. Either way, no one should settle for bird’s nests.”

Read more: Additive Manufacturing: 5 Things You Need to Know About 3D Printing

The problem, as many machine facility owners and procurement people will attest, is carbide’s higher cost. This viewpoint is especially prevalent in job production workplaces and other high-mix, low-volume manufacturers. Again, HSS might be just the ticket here, but Dominski and his colleagues agree that carbide almost always produces a lower cost per part.

“So many people are still stuck on the upfront cost and don’t see the benefit of spending the extra money for carbide,” he says. “But I can offer multiple examples of shops paying for the tool on a single job. For instance, we recently worked with a shop drilling 4.42-millimeter holes in 304 stainless steel that went from 425 holes per tool to 4,000 with carbide, while another customer drilling titanium increased tool life more than eight times.”

Those examples are fairly typical, he adds, and neither of them mentions carbide’s greater productivity, which is significant. Granted, it’s not for every application, but on stainless steel and other tough materials, solid carbide drills are a no-brainer.

What tips can you share for drilling stainless steel, one of the more challenging metal groups? Post your thoughts and insights in the comments below.

Tool life management software and CNC machine tools that track tool usage are increasingly common.

For facilities so equipped, there’s even more reason to give carbide drills a try, whatever you’re machining.

That’s because it’s a simple enough matter to serialize these admittedly more expensive tools and then keep track of the number of holes or inches drilled, thus maximizing the investment.

These systems also make managing re-grinds on carbide drills and end mills easier, further increasing return on investment.