Case Study: NEW Aluminum Advanced Productivity Roughers – S-Carb APR

The S-Carb Advanced Productivity Rougher (APR) from KYOCERA SGS Precision Tools was engineered for high power, high-efficiency machining of aluminum aerospace structural parts.

The S-Carb Advanced Productivity Rougher (APR) from KYOCERA SGS Precision Tools was engineered for high power, high-efficiency machining of aluminum aerospace structural parts.

The S-Carb Advanced Productivity Rougher (APR) was engineered for high power, high-efficiency machining of aluminum aerospace structural parts. Material removal rates of 550 cubic inches are achievable with remarkable tool life and product finish. The APR's MRR capabilities are nearly six times that of its nearest competition based on lab testing.

It is easy to see why KYOCERA SGS Precision Tools is known around the world as an authority in aluminum machining with the power and capability of the APR and its sibling tool, APF. The 3 and 4 flute offer variable pitch geometry for reduced vibration. In the following short video, KYOCERA SGS demonstrates an aluminum aerospace component being machined with the APR 3 and 4 flute roughers.

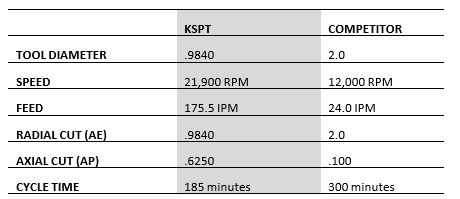

KYOCERA SGS Precision Tools (KSPT) put its S-CARB APR to the test in this Case Study of a milling application in the aerospace industry. The competitor product was an indexable cutter and the application used flood coolant. The goals of this study were to significantly reduce cost through an increase in tool life.

The overall findings of this study indicate that although KSPT’s S-Carb APR was priced significantly higher than the competition, the manufacturing efficiencies gained with a superior tool vastly outweigh the extra dollars spent up front. The speed at which the tool was run was able to be increased 45% and with that increased speed, the feed rate was able to be increased over 150 in/min! The APR was also able to produce 1/3 more parts with roughly 1/3 less tools.

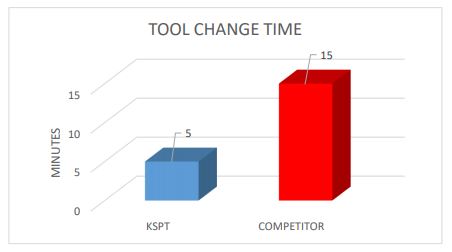

When you combine the time that was saved in cycle time with the time saved in tool change, you significantly lower the total machining time. With that efficiency comes the cost associated with it, and in that regard, KSPT was able to save the customer over $150,000. All these manufacturing efficiencies combined equaled a total cost savings of $150,292.92!

See the complete Case Study to learn more about how the S-CARB APR stacked up against the competition.

You can find the complete line of products from KYOCERA SGS Precision Tools on MSCDirect.com.

KYOCERA Precision Tools is a world-class manufacturer of indexable tooling solutions. At KYOCERA, we’re passionate about revolutionary cutting tool technology. We design and develop advanced indexable cutting tools that not only meet but exceed quality expectations, all while delivering the cost-efficiency that today’s metalworking professionals need to stay competitive in a variety of industries including, aerospace, automotive, medical, small parts, and mold & die