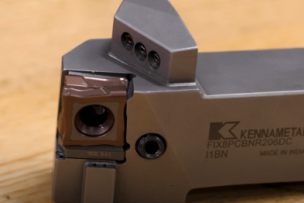

Kennametal delivers productivity to customers seeking peak performance in demanding environments by providing innovative custom and standard wear-resistant solutions, enabled through our advanced materials sciences, application knowledge, and commitment to a sustainable environment.

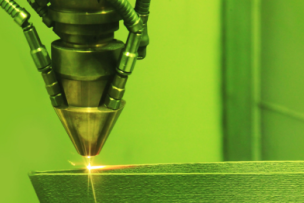

Kennametal Inc. recently announced that it has been named a winner of a prestigious R&D 100 Award for its innovative additive manufactured machining tool for large engine and transmission housings in transportation, including electric vehicles, made with new KENionic™ technology.

copy 3.jpg?itok=jDQ0Lywg)

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *