Kennametal delivers productivity to customers seeking peak performance in demanding environments by providing innovative custom and standard wear-resistant solutions, enabled through our advanced materials sciences, application knowledge, and commitment to a sustainable environment.

Polycrystalline diamond round tools, available with short lead times, enable high-efficiency aluminum machining.

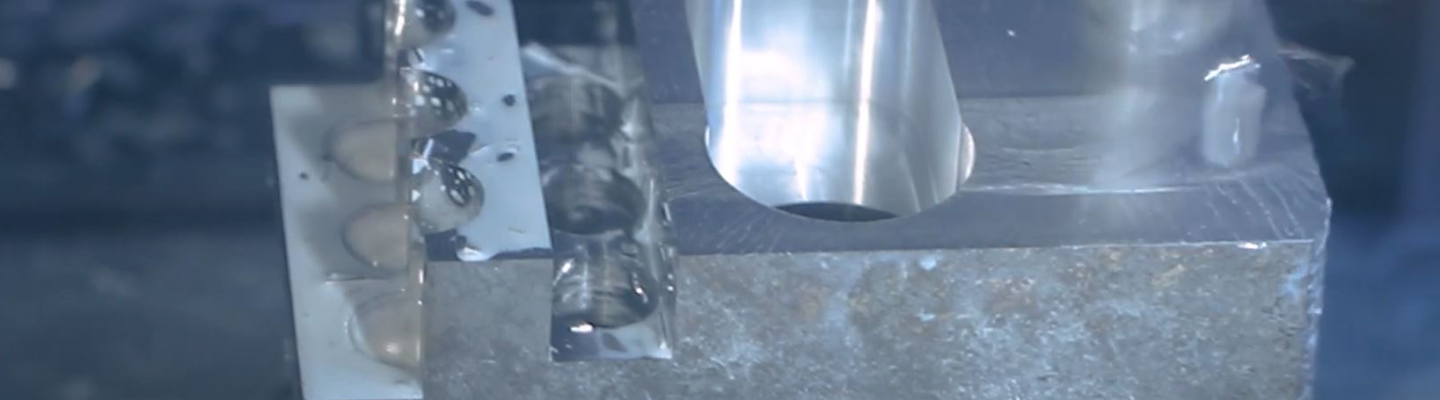

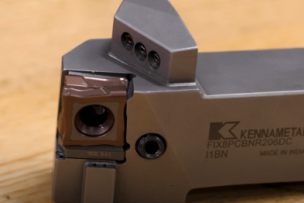

Kennametal has introduced a new line of PCD round tools for aluminum machining that delivers up to 10 times higher productivity than carbide tooling. The new line of drills, reamers and end mills provides exceptional tool life and wear resistance even in very abrasive aluminum alloys and are available with very short lead times.

copy 3.jpg?itok=jDQ0Lywg)

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *