Kennametal delivers productivity to customers seeking peak performance in demanding environments by providing innovative custom and standard wear-resistant solutions, enabled through our advanced materials sciences, application knowledge, and commitment to a sustainable environment.

Imagine burying a roughing tool in a block of Ti-6Al-4V titanium and ripping away more than 1000 cm3 (61 cubic inches) of material in just one minute. If you’d been at a recent test of Kennametal’s new HARVI™ Ultra 8X helical milling cutter, you’d have seen exactly that. Using a 95 mm (3.74 in.) axial depth of cut, 20 mm (0.78 in.) radially, and a feed rate of 423 mm/min (16.65 IPM), the 80 mm (3.15 in.) diameter HARVI Ultra 8X plowed through this difficult aerospace superalloy for nearly three minutes straight without flinching.

Maximum Excitement

Tim Marshall, senior global product manager for indexable milling, has tested the HARVI Ultra 8X with a variety of customers, pushing the limits of the new cutter on everything from 15-5 PH to cast iron to Aermet 100 (high strength steel) and seeing outstanding results with each.

“Kennametal developed the HARVI Ultra 8X to meet two distinct needs,” Marshall says. “The first came from the aerospace industry, which thanks to the large numbers of aircraft being built today requires the highest metal removal rates possible but still achieving excellent tool life. At the same time, machine tool builders and users alike are asking for tools able to withstand higher cutting speeds but generate lower machining forces, so as to reduce wear and tear on machine components during extreme cutting conditions. The new HARVI Ultra 8X does all that, and a lot more besides.”

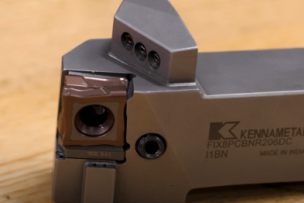

HARVI Ultra 8X. The bolt taper flange cutter with a KM4X adaptor provides unmatched stability.

copy 3.jpg?itok=jDQ0Lywg)

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *