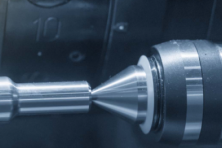

Case Study: For Success Micro-Mechanics Utilizes a Complete System Approach

Reaching the next level in productivity is not about the incorporation of individual products, but rather the integration of complete systems that work together to help manufacturers realize greater efficiencies. At Micro-Mechanics, they have done just that to increase productivity, profitability and a global competitive advantage.