The 3M™ E-A-Rfit™ Dual-Ear Validation System is based on field microphone-in-real ear (F-MIRE) technology. The system consists of a specially designed loudspeaker equipped with a digital signal processor that allows for a consistent presentation of the test signal and real-time communication between the microphones, speaker and software. Specially designed, dual‐element microphones make it possible to measure the sound level at 2 different locations and for both ears simultaneously. The external microphones measure the level of the test signal outside the ear. The internal microphones are connected to one of the specially modified 3M™ probed hearing protectors to allow measurement of the sound level inside the wearer’s ear canal while the hearing protector is worn. The 3M™ E‐A‐Rfit™ Dual‐Ear Validation System also has earmuff testing capabilities. Both ears are accurately measured simultaneously, and in less than 5 seconds, a personal attenuation rating (PAR) is displayed.

It Starts with PAR

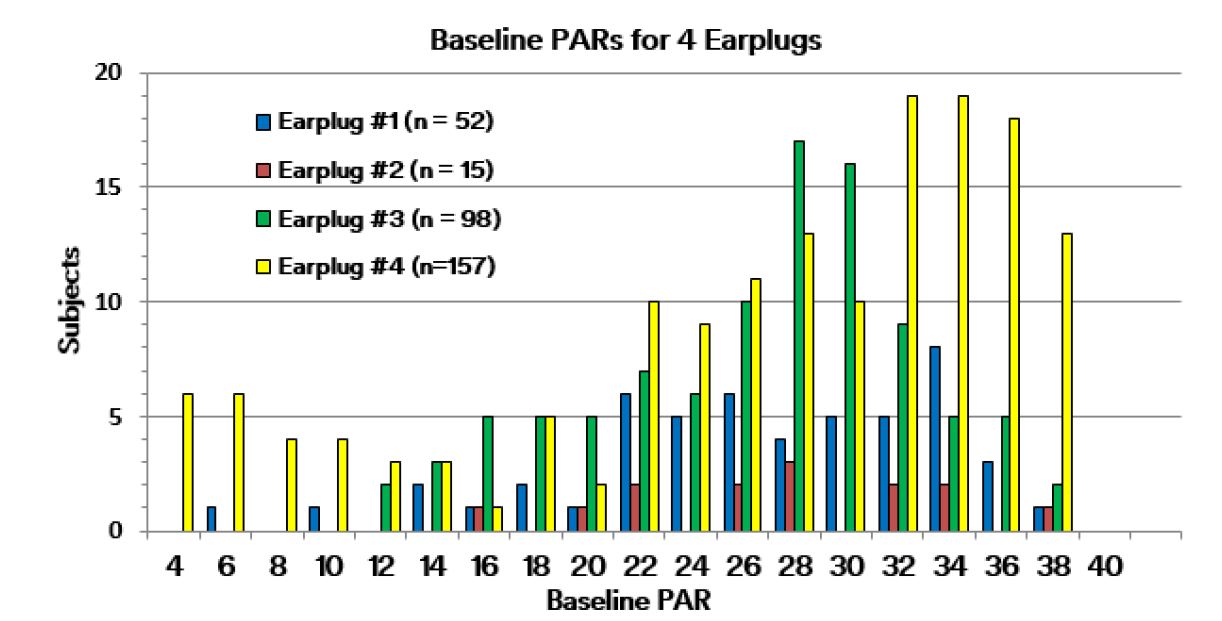

The measurement of attenuation for a fit tested hearing protector is displayed as a PAR. To be sure that your employees are getting the protection they need, you should to know the PAR of every employee. Hearing protector ratings such as the noise reduction rating (NRR), the single number rating (SNR) and the sound level conversion (SLC80) are derived from measurements gathered in a carefully controlled laboratory environment. Although the ratings are an accurate measurement of the capabilities of a particular hearing protector under the specific test conditions, they may not represent what an individual worker will achieve when the device is worn. Most employees receive adequate protection, while some may not if they are not using the hearing protector correctly or have not chosen the correct size or style (Figure 1). Note the wide range of PAR values tested on 4 earplugs considered high attenuating according to their labeled values.

Why use PAR vs. the labeled value?

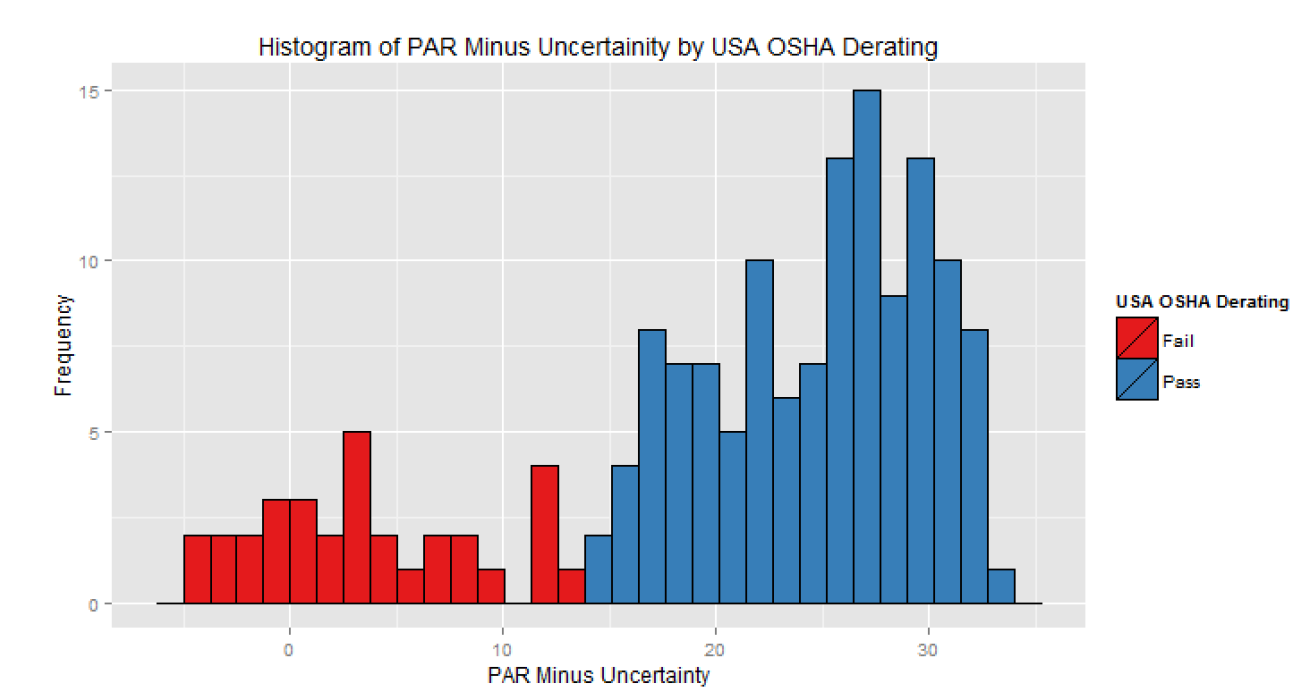

Figure 2 displays PAR values for earplug #4, measured on 157 employees. The blue represents the workers with PAR values (minus their uncertainties), who achieved at least the OSHA derating value or more. But the PAR values in red indicate the workers would have not met the derated criteria. This highlights the importance of using individual worker attenuation data rather than labeled values, even when derated, to predict user protection.

WHO do you test and who conducts the testing?

Who Should Be Tested?

The target population is presumably the group of employees expected to be at risk for noise-induced hearing loss (NIHL) and may either be limited or broadly defined. Examples of target populations include:

Newly hired employees

Employees with a measured temporary threshold shift (TTS) or standard threshold shift (STS)

Subset of employees who work in the highest noise areas or are required to wear dual hearing protection

Subset of employees who are at the margins of inclusion for mandatory hearing protection

Subset of employees exposed to ototoxic chemicals as well as to noise

All employees who qualify for inclusion in the hearing conservation program

All employees regardless of noise exposure at work

Who Conducts the Fit Tests and/or Manages the Fit-Test Program?

In general, those responsible for the HLPP will manage the fit-test program. Examples of personnel typically responsible, previously referred to as operators, for conducting fit tests include:

Industrial hygienists

CAOHC certified personnel

Safety professionals

Occupational health nurses

Vendor-trained personnel

Independent or authorized service providers

HOW do you use the 3M™ E-A-Rfit™ Dual-Ear Validation System?

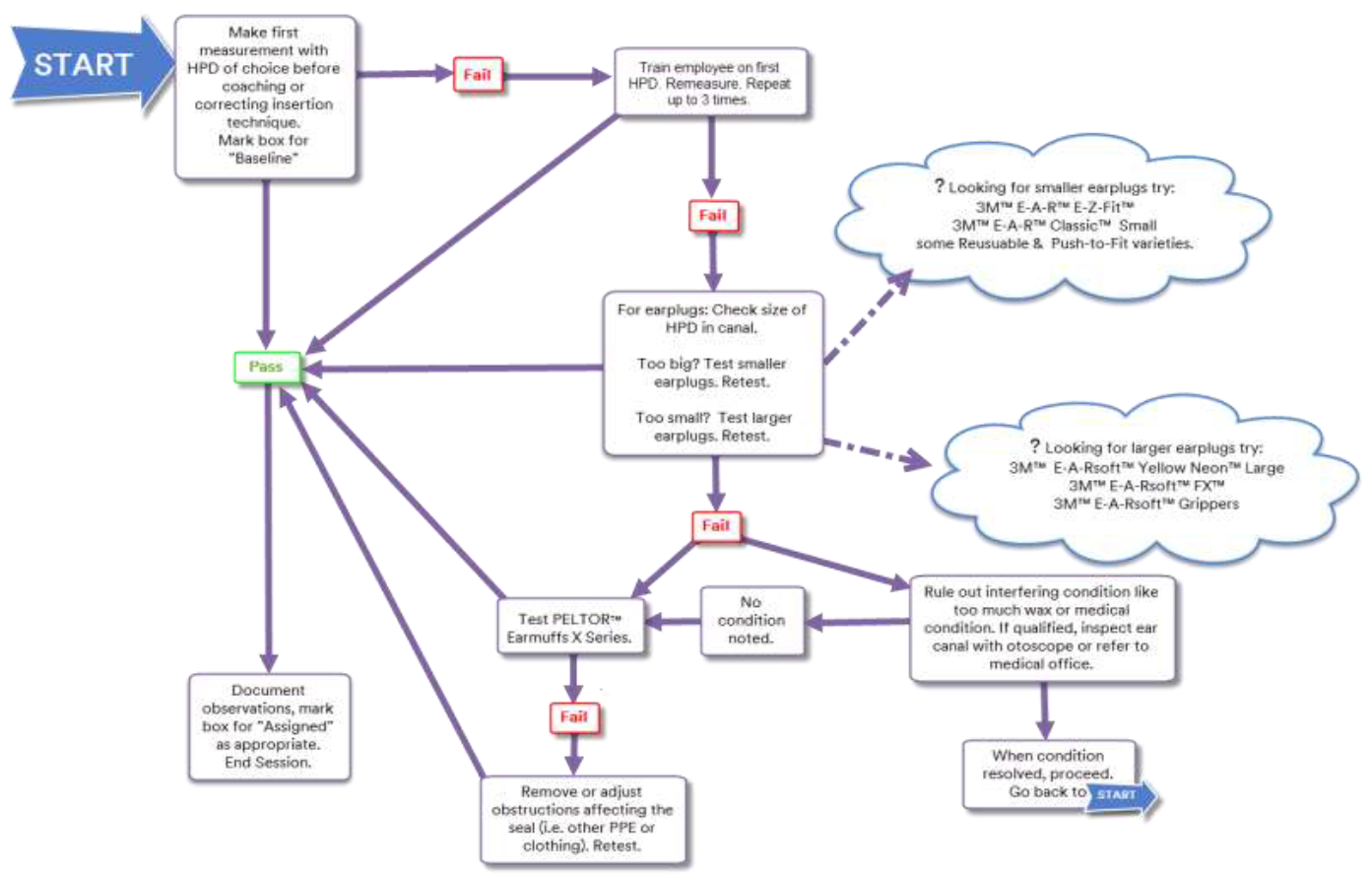

Newly hired employees unfamiliar with hearing protector use will require careful training along with fit testing to ensure they are adequately protected against the hazardous noise. All other workers could follow the decision tree below (Fig 3) when conducting fit tests for the first time. Baseline measurements capture how employees “normally” wears their hearing protectors and serve as a benchmark for all future measurements. Caution: HPD fit testing should not be performed on employees experiencing ear pain on the day of testing.

How Much Protection Do Employees Need?

Each employee’s target PAR is based on the company exposure limit and the employee’s exposure. For example, if Employee A has a time-weighted average (TWA) of 95 dBA and the company exposure limit is 80 dB, then the employee must receive a PAR of at least 15 or above in order to “Pass”. If the employee achieved 10-dB PAR, then the measurement will display “Fail”.

Example: 95 dBA TWA

-80 dBA Company Exposure Limit

___________________________

15 dBA Target Minimum PAR

How Often Should You Fit Test?

Much like audiometric testing, hearing protector fit testing is not a one-time event. Ideally, all employees in your hearing conservation program should be initially fit tested. For those who required extra training and/or a new size or style hearing protection, early follow-up is recommended to be sure the employee has access to the newly assigned hearing protectors, is wearing the usual or newly assigned hearing protectors, and the HPD is continuing to provide adequate protection. Annual HPD fit testing can provide assurance the hearing protectors are being worn correctly and give additional opportunity for further hearing conservation training.

How is fit testing conducted and where?

The physical location for testing may vary depending on your company but implementing fit testing is more efficient and effective if:

The fit-test location is centrally located and easily accessible to the workers.

Managers and supervisors are engaged in the process and can assist in assuring the workers can leave their workstations to be fit tested quickly and on a timely basis.

A flexible schedule with individual time slots is employed.

A “wrangler” is designated who can assist and ensure the efficient flow of workers to be tested.

Educational materials and tools are available if additional training is required.

A complete selection of hearing protector samples of all types that are used at the plant is available to give to workers, especially for cases in which they have been “reassigned” a different size or style based on fit test results.

WHY use the 3M™ E-A-Rfit™ Dual-Ear Validation System?

Incorporating fit testing within an HLPP results in a multitude of benefits. The list below highlights the most compelling reasons why you should use the 3M E-A-Rfit Dual-Ear Validation System.

Identify workers with low PARs who are consequently at risk for developing NIHL.

Verify the performance of HPDs without relying on laboratoryderived labels and derating schemes that are intended for groups of employees and not individual workers.

Train and motivate employees on the proper use and fit of HPDs.

Select and assign HPDs based on noise exposures, expected protection levels and the anatomy of the worker’s ear canal.

Train personnel responsible for teaching employees the proper use and fit of HPDs.

Provide a useful standard-threshold-shift (STS) follow-up procedure that can be used to determine whether the problem may be related to either the fit or the attenuation capabilities of the HPD.

Provide data that may be accepted by regulatory agencies as a better alternative to using labeled attenuation values and derated to assess HPD adequacy.

Audit departments to evaluate overall HPD effectiveness and suitability.

Provide potentially useful documentation to demonstrate hearing loss prevention efforts conducted by a company that go beyond regulatory requirements.

More Information:

3M™ E-A-Rfit™ Dual-Ear Validation System Website – http://3M.com/earfit

User Support Website – http://earfit.3M.com

Third-Party Validation Studies

Trompette, N. & Kusy, A. (2013)

Voix, J., Pienkowski, J., & Delnavaz, A. (2014))

Dyrba, P., Dantscher, S., Augustin, S., Fritsch, T., Sikert, P. (2014)

Published Field Research

Smith, P., Monaco, B., & Lusk, S.L. (2014)©

Brought to you by 3M

When it comes to fabricating, assembling or processing anything around the world, 3M knows efficiency is key. From ultra-strong abrasives that keep processes running smoothly, to futuristic materials that literally lighten your workload. 3M innovative solutions keep your business and your employees working smoothly with innovative industry leading solutions in abrasives, PPE and facilities safety solutions and adhesives and tapes.

Related Articles

Worthy Waterproof Gloves You'll Want to Wear

![Why the Cheapest Safety Gloves Aren’t Always the Smartest [Infographic]](https://images.ctfassets.net/5j4ln2up7bt7/2gVEyRZylkBIlvTDtTRRc7/dde0c00e4846d6a88d56a7a68f09332a/mcr-PD5931_action4571-thumb.jpg)

Why the Cheapest Safety Gloves Aren’t Always the Smartest [Infographic]

NFPA 30 and Safe Storage of Flammable Liquids

Why Mental Health Belongs in Every Safety Conversation