Products that work as hard as you do. From the most basic to the most specialized needs, 3M offers the health and safety protection you and your workers need most, so everyone can perform at their best. We strive to deliver comfortable, well-designed personal protective equipment (PPE) that offers your workers the most effective protection available.

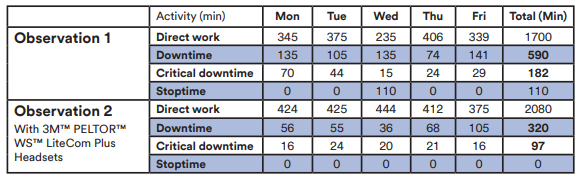

Researchers in the Civil Engineering program at Lund University in Sweden conducted a case study to examine the effect of radio communication on productivity within a civil engineering project. This research indicates that when using radio communications the critical downtime for the work team in the case study decreased almost 50%, an average of 17 minutes per 8 hour workday.

Methodology

This study is based on observations on a construction project. The project was chosen because of its repetitive and homogenous activities, which makes it suitable for comparing weeks over time. The study included two observations during separate weeks. The study was executed according to the following plan:

- Pre-study and defining the objects to observe

- Observation Team without headsets

- Headset* classroom Training

- Headset* Introduction and dry-run with Team

- Observation Team with headsets*

- Interviews

The team included four officers, three operators, and six workers performing earth excavating, laying pipes, tubing, tube welding, and refill. First the team was performing their tasks as usual and the second time the team was wearing 3M™ PELTOR™ WS™ LiteCom Plus Headsets.

A typical work day for the team members:

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *