While anyone who works with electricity quickly develops a healthy respect for anything that could possibly be live, even the best of us can make uncharacteristic mistakes when pushed for time. The following is a quick list of WHAT NOT TO DO when taking electrical measurements.

DO NOT:

1. Replace the original fuse with a cheaper one. Digital multimeters (DMMs) that meet today’s safety standards include a special high-energy fuse designed to pop before an overload hits your hand. Fluke meters use a special sand-filled fuse designed to extinguish an arc within the fuse enclosure. Be sure to replace it with the same kind of authorized fuse.

2. Use a bit of wire or metal to get around the fuse. That may seem like a quick fix if you’re caught without an extra fuse, but it won’t provide protection against a spike headed your way.

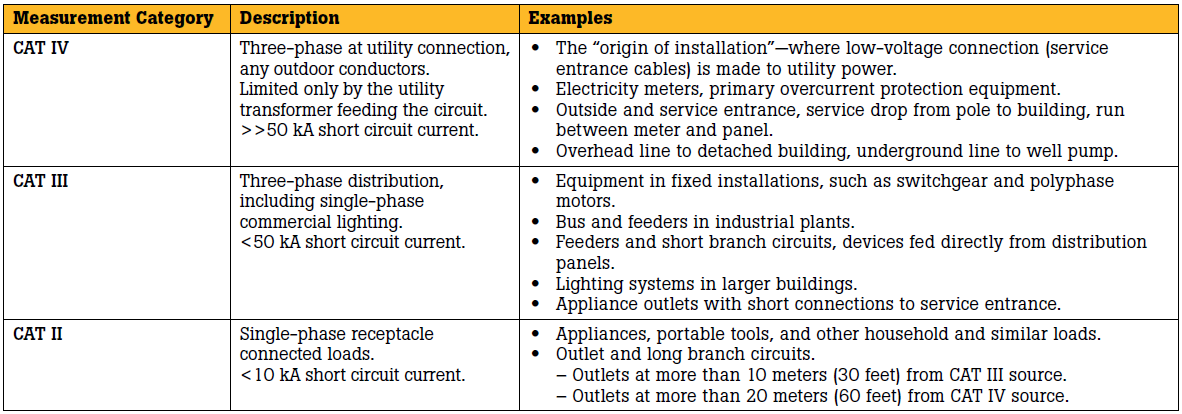

3. Use the wrong test tool for the job. Make sure your test tool holds the correct CAT rating for each job you do, even if it means switching DMMs throughout the day. (See Table 1)

4. Grab the cheapest DMM on the rack. If that cheap test tool doesn’t actually have the safety features it advertised, you could end up a victim of a safety accident. Look for independent laboratory testing markings like CSA or UL that ensure the tool meets standards.

5. Skip out on PPE. They’re called “safety” glasses for a reason. Take them out and put them on. The same goes for insulated tools, insulated gloves, ear plugs, your face shield/hood and arcresistant clothing.

6. Work on a live circuit. De-energize the circuit whenever possible, and verify it’s de-energized before starting work. If you have to work on a live circuit, make sure an arc flash risk assessment has been completed, use the NFPA 70E table H.3(b) to select the appropriate PPE, and verify the operation of your test tool by testing a known voltage source first.

7. Fail to follow lockout/tagout procedures. Lockout/tagout procedures exist to protect you from potentially fatal electric shock—don’t risk someone re-energizing your work environment.

8. Multi-task while measuring. When working with live circuits, try not to hold the meter in one hand while testing with the other—in a transient situation, that could create a path toground through your heart. Hang or rest the meter or use a wireless read-out to get the meter out of your hands and the readings at eye level, and use an alligator clip for your ground, so that that you’re only using one hand to probe the energized conductor.

9. Neglect test leads. Test leads are a critical component of DMM safety. Make sure your leads match the CAT level of your job. Look for test leads with double insulation, shrouded input connectors, and test probes with finger guards and a non-slip surface. Test the leads with a known voltage before using. Consider leads with adjustable shrouds. There are even probes with built in fuses!

10. Hang onto an old test tool forever. Today’s test tools contain safety features unheard of even a few years ago. These features are worth the cost of an equipment upgrade and a lot less expensive than an emergency room visit. For example new standards restrict the length of metal in the tip of a test probe to 4mm or less in CATIII/IV environments.

MSC can help you create a safer workplace to keep your team protected from electrical hazards. For a free assessment, training, programs and products to stay safe, visit mscdirect.com.

Brought to you by Fluke Corporation

Fluke® Tools Corporation founded in 1948 is the world leader in compact, professional electronic test tools. Fluke tools range from electrical test equipment, precision measurement & quality control to HVAC. Fluke products are designed for day-to-day field troubleshooting and maintenance of electrical systems, electrical power systems, HVAC/R systems, and associated equipment. Find a wide variety of Fluke electrical test tools at mscdirect.com.