Women have a particular challenge with ill-fitting PPE, although Oliphant and Francis acknowledge that great strides have been made in safety equipment and clothing to address this concern.

There are other reasons that workers won’t wear PPE, however, and they might surprise you.

1. There Is No Safety Culture

Imagine being new to a job and seeing that your co-workers aren’t wearing their PPE. Without saying a word, a clear message is sent about how the workplace values safety, especially to new hires.

“The safety culture makes a huge difference,” Francis says. “Maybe they are influenced by their peers not to wear PPE, because they’re embarrassed. They’re like, ‘No one else is doing it. Why would I?’”

Solution

Workplace safety culture must start at the top, with management underscoring the importance of PPE and why employees should wear it.

“Let’s go on safety walks so that we can identify how many people are not wearing PPE,” Francis explains, “and then let’s start asking the employees: Why are you not wearing it? What can we do to help you?”

Oliphant adds, “If management backs their safety program, then it changes the culture, and the workers will wear it—if it’s comfortable and if they can do their job with it on.”

Read more: PPE Assessment Plan: Selecting the Best Type for Your Business

2. Training Isn’t a Priority

Along with safety culture, training is key to PPE compliance that can be missed by management. “Employers either don’t want to spend the time or money it takes on the training or they don’t have a competent person to speak to the training.” Francis says.

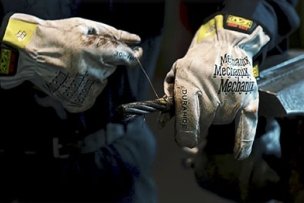

A lack of PPE training results in situations like this: “While I was doing a walkthrough, a worker’s glove was ripped, it had holes in the thumb saddle, and they even cut the tips of the fingers off,” Francis says. “I asked him if he thought those were safe to wear, and he legitimately thought it was fine—he stated he didn’t know any better and was never trained. Next steps would be to check employer training records on if they were trained on the proper care of PPE, what the usage is, and when to take it out of service. I recommend weekly refreshers during toolbox talks to.”

Solution

To prioritize PPE training, you must put resources behind it. Think of it as an investment rather than a cost.

If safety managers are too busy to train all employees on PPE (or any other safety topic), consider reaching out to professional safety services or leveraging modern training solutions. Ultimately, training will be less expensive than an injury claim.

Read more: How to Tell When It’s Time to Replace Your PPE

3. Workers Don’t Realize It’s a Problem

Call it overconfidence or a false sense of safety, but many workers simply don’t think they need to wear PPE.

“There is the mentality of: I know what I’m doing, and it’s not going to happen to me,” Oliphant says.

Solution

Explain that accidents can—and do—happen, even to experienced workers. Francis recommends sharing safety scenarios to explain the why behind PPE.

“If they’re cutting cardboard boxes with a razor blade, say, ‘Hey, why aren’t you wearing your gloves?’ And the worker’s like, ‘I was just getting kind of sweaty.’ You could say: ‘OK, take them off, take a five-minute break, let them air out, and then put them back on. Somebody had a serious cut last week, and they ended up having to go to the hospital, and I don’t want that to happen to you. I want you to go home the same way you came here today.”

4. Employers Buy Cheap PPE

When margins are tight, it’s understandable to save costs by controlling spending on certain line items. When it’s done at the expense of reliable PPE, however, that’s a mistake.

“I highly discourage going for the cheapest glove or the cheapest eyeglasses,” Francis says.

The least-expensive PPE products often don’t have the features that workers find comfortable to wear, so they won’t wear them.

“Money is an issue,” Oliphant says. “Some employers aren’t going to spend that extra money to buy the PPE that fits better.”

Solution

Talk to your distributor about your options, or research suppliers that offer PPE assessments. These resources can raise your awareness of what’s out there.

“You can find comfortable PPE for your employees in your price range,” Francis says. “Reach out to your distributor or whomever you’re getting your gloves or glasses from. Ask them if there are other valuable options that have the comfortable nosepiece or the adjustable temples. Maybe I’m not going $2 more—I’m only going 15 cents more.”

Read more: 3 Ways High-Tech PPE Is Outsmarting Workplace Hazards

5. Management Isn’t Listening to Workers

If your employees don’t like something about their PPE, how would you know? The first sign could be noticing that they’re not wearing PPE on the job—or worse, the first sign could be an injury.

Solution

Create an environment where employees are free to give feedback. “An employer has an obligation to provide proper-fitting and comfortable PPE for workers to reduce injuries in the workplace,” Francis says.

“It’s important to ask employees why they do not like the PPE and what they would like to see instead,” she says. “Let them have a conversation with you and some communication that you value their opinion. I think that will go a long way in them wearing the PPE.”

Ready to choose? Here’s How to Pick the Right PPE: Outer Protective Gear

Is there another reason that workers won’t wear PPE that didn’t make this list? Let us know in the comments.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *