A Disposable Glove Program is an important part of managing safety in your operation. The selection of the right Disposable glove solution for workers depends on their operating environment. The wide range of single use gloves available today are designed for use in a range of applications including General Purpose, Industrial, Medical and Food environments. This guide serves as an overview of factors in the selection of the right glove in various risk environments.

What are the differences between the various disposable gloves?

Disposable gloves are primarily differentiated by their features, polymer science and manufacturing technologies.

The primary features of disposable gloves are…

Grade

• Examination

• Classified as a medical device

• Prevents contamination between caregiver and patient

• Industrial

• Industrial or general purposes

• Not for contact

Powder

• Powdered – Easier on/off; better moisture absorption

• Powder-Free – No powder to contaminate products

Texture

• Full – Entire glove has a raised texture to improve grip

• Fingers-only – Texture on fingers only

• Smooth Finish – No texture; good when less resistance is desired

Glove Length

• Standard glove length is 9.5 inches

• Extended cuff provides additional protection to wrists and forearms

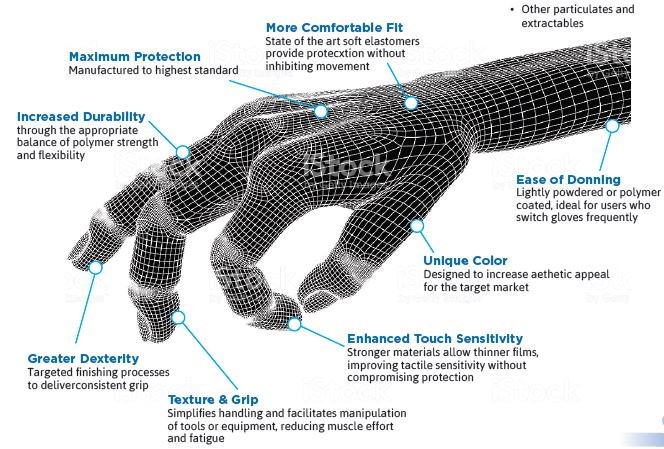

What Makes a Good Disposable Glove?

Polymer science and manufacturing technologies combined to deliver increased comfort, protection and productivity.

A common practice is to focus primarily on glove thickness. Glove thickness alone doesn’t translate to user requirements. There are a number of product differentiators that are important to review with your customers:

Barrier Integrity – people wear gloves for a reason; better barrier integrity = more consistent reliable protection

Durability – there are a lot of cheap gloves on the market; if a user has to continue to replace gloves due to breakage, they end up spending more in the long run

Grip – plays an important role in productivity; it is important to understand a users grip requirements, wet or dry; some users prefer gloves that are less grippy or tacky

Touch Sensitivity – how important is tactile sensitivity to your customer? Having poor tactile sensitivity can affect productivity and have potential implications with safety

Glove Color – may not seem like a big deal, but color can be used to differentiate departments and compliance; sometime there is just a “cool” factor with wearing a unique color, such as black nitrile.

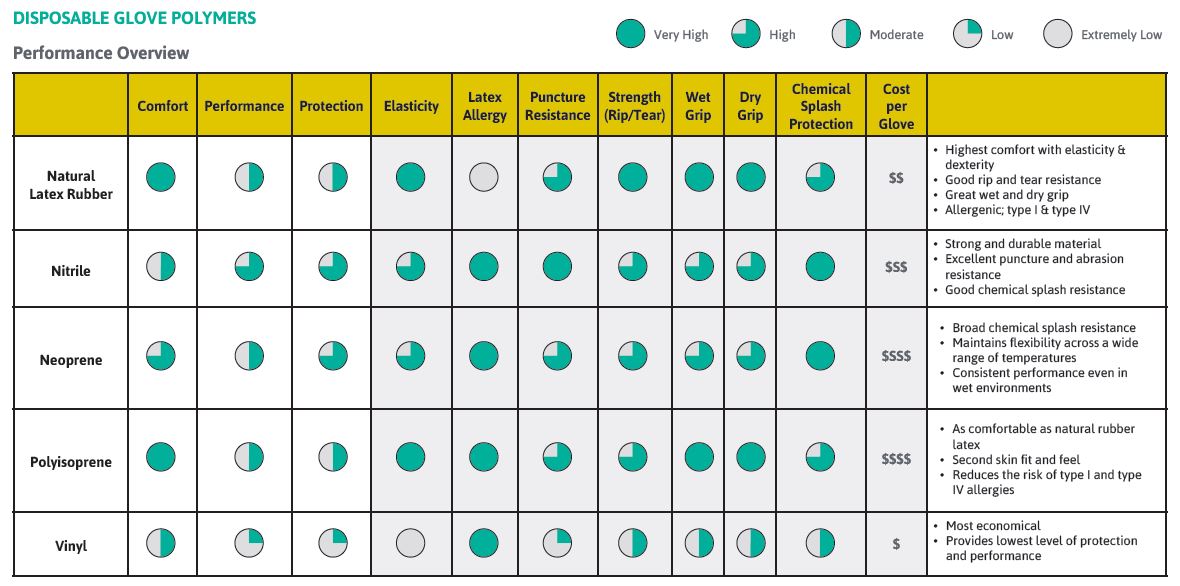

How Do I Select The Proper Disposable Glove?

What manufacturing applications are the gloves to be used in?

• What are their performance requirements?

• What tasks are they doing?

• What do they like or dislike about their current glove?

Confirm their requirements for the following factors:

• Wet/ Dry Grip

• Comfort/Ergonomics

• Tactile Sensitivity

• Durability

• Residue Free

• Chemical Splash Protection

• Expanded Protection

• Cost

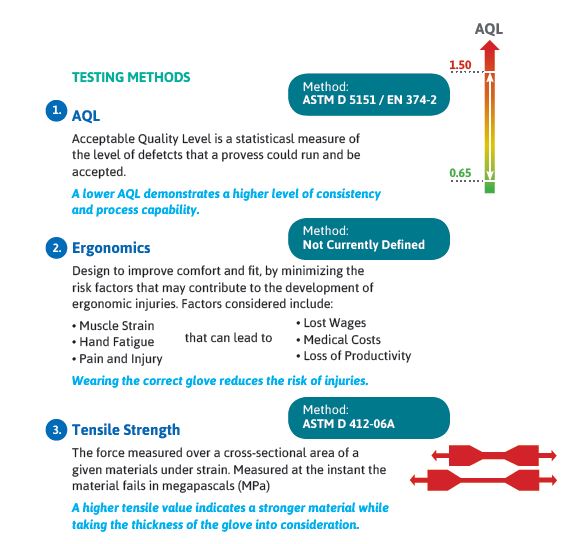

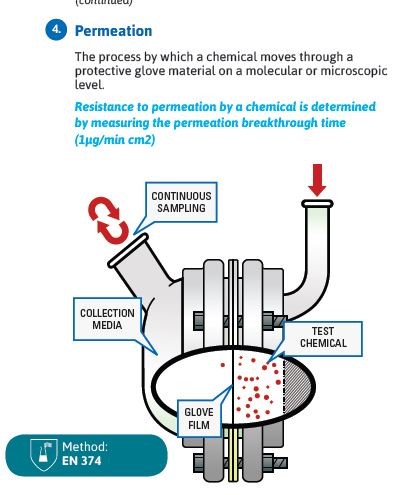

How Do Glove Manufacturers Test For Chemical Resistance?

Multiple test methods are commonly used to determine chemical permeation, tensile strength, AQL and ergonomics.

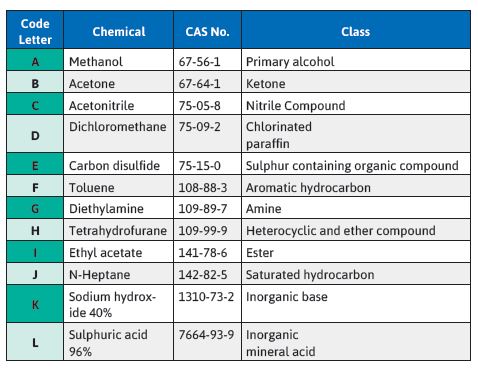

Chemical permeation tests are based on any 3 of the 12 chemicals from the list below. If the permeation time is 30 minutes for those 3 chemicals, the glove can receive theErlenmeyer “chemical resistant” pictogram with at least 3 code letters.

This does not mean this glove only works with the selected chemicals, but that the selection reflects the glove material’s primary application.

The EN374 standards also determine:

• Gloves achieving a breakthrough time less than 30 minutes but pass penetration test requirements (Acceptable Quality Level [AQL] <= 4.0) shall carry the “waterproof” pictogram (commonly seen with disposables);

• Gloves that pass penetration test requirements and achieve an acceptable quality level (AQL <= 1.5) shall carry the “microorganism” pictogram.

Penetration time is used to determine the material’s performance level or rating. Levels range from “0” (under 10 minutes) to “6” (up to 480 minutes, the maximum time that can be claimed under the current EN374 standards).

Penetration test requirements are met when no evidence of air or water leak occurs, based on an acceptable quality level (the percentage of allowable rejects from a known number of inspected samples).

Gloves not complying with the permeation test but meeting penetration requirements must use the pictogram marking with a question mark.

Brought to you by Ansell

Ansell manufactures innovative products that provide unmatched quality, comfort and technology to millions of consumers, workers and first responders. All our gloves benefit from over 100 years of Ansell research and development, patented technology and state of the art manufacturing. Anywhere in the world Ansell helps workers finish their job more safely, more comfortably and more productively.

Related Articles

Safety Glasses and Goggles Selection Guide: Complete Eye Protection Standards

Accelerator-Free Gloves: Rethinking Hand Protection for Sensitive Skin

Worthy Waterproof Gloves You'll Want to Wear

![Why the Cheapest Safety Gloves Aren’t Always the Smartest [Infographic]](https://images.ctfassets.net/5j4ln2up7bt7/2gVEyRZylkBIlvTDtTRRc7/dde0c00e4846d6a88d56a7a68f09332a/mcr-PD5931_action4571-thumb.jpg)

Why the Cheapest Safety Gloves Aren’t Always the Smartest [Infographic]