In the world of workplace risks, heat stress is a triple threat: Common, potentially deadly and often overlooked.

Millions of U.S. workers are exposed to heat on the job, and although illness from heat exposure is preventable, thousands become sick from it every year, the U.S. Occupational Safety and Health Administration notes.

Some of those cases are fatal.

Extreme heat was the third-highest weather-related cause of death in 2022 with 383 fatalities, according to the latest statistical information from the National Weather Service.

The ranking holds on a long-term basis as well, with extreme heat killing an average of 176 people a year in the 30 years from 1993 to 2022, according to the weather service.

Occupational risk factors include:

Heavy physical activity

Warm or hot environmental conditions

Lack of acclimatization (most outdoor fatalities occur in the first few days of working in warm or hot environments because the body needs to build a tolerance to the heat gradually, OSHA notes)

Wearing clothing that holds in body heat

Hazardous heat exposure can occur indoors or outdoors and during any season if the conditions are right, not just during heat waves, OSHA says.

Explore HEAT STRESS PREVENTION products & solutions on mscdirect.com.

To combat heat stress, employers should make sure their workers are adequately hydrated and their facilities are sufficiently cooled and ventilated. Here are some tips to identify and prevent heat stress.

Read more: Winter Dehydration Facts: Causes, Symptoms and Prevention Tips

Keeping Workers Hydrated

Dehydration is no minor problem in industrial and manufacturing environments. It starts to happen before there are any glaringly obvious symptoms. What’s more, workers often don’t think they are becoming dehydrated if they aren’t hot or sweating profusely. And they typically aren’t thirsty.

The heavy personal protective equipment (PPE) required in industrial and manufacturing settings can drive up body temperatures and induce sweating, as can working in a hot warehouse or production facility. PPE that increases body temperature includes arc flash suits, vests, helmets and gloves.

Dehydration is not solely an issue in the summer. It’s a year-round concern that’s just as likely to be brought on by cold stress as by extreme heat.

Scientific research shows that even mild dehydration (the kind that’s asymptomatic) profoundly affects productivity. It can reduce a worker’s reaction time, which can make the chance of an accident more likely—a dangerous prospect when working in a manufacturing environment or when doing any job that involves operating heavy machinery.

When you sweat, you lose minerals—the electrolytes that are found in your muscle cells: sodium, potassium, calcium and magnesium. These electrolytes ensure the proper muscle response so that people can operate at peak performance.

Indeed, elevated temperatures make us prone to error, according to a report in Safety+Health magazine, which cites a NASA study that concluded that when the temperature is 95 degrees for an extended period, people can make 60 mistakes per hour—without realizing it. This happens because blood moves to the skin to produce perspiration to cool the body, so other organs, including the brain, receive less blood than they normally need, interfering with cognitive capability.

Read more: Common Causes of Dehydration—Fact vs. Fallacy

HVAC Cooling and Safe Ventilation

Cooling the air in industrial settings has become more complicated for companies as they seek to simultaneously limit the spread of airborne viruses.

The Centers for Disease Control and Prevention (CDC) offers updated guidance on how employers and building managers can ensure proper ventilation.

These measures, which include steps to increase ventilation safely and keep HVAC systems properly maintained, include:

Opening outdoor air dampers beyond minimum settings to reduce or eliminate HVAC air recirculation

Using a window fan, placed safely and securely in a window, to vent room air to the outdoors and draw outdoor air into a facility without generating strong room air currents

Increasing air filtration to the highest possible level without significantly reducing designed airflow

Using portable high-efficiency particulate air (HEPA) fan/filtration systems to enhance air cleaning

Read more: Air Filtration: What Are MERV Ratings, and How Do They Protect Your Workers?

Ensuring a facility is well ventilated and providing cooling stations for workers can help prevent heat-related health issues, according to the CDC.

Increased air movement from fans makes workers feel less warm. And using fans in conjunction with central air conditioning systems can make them more effective, too, as fans use a smaller amount of energy than an HVAC system and so cut your overall energy consumption.

Portable air conditioning units can help control heat in areas that become especially hot.

Avoiding Overheating Equipment

In addition to keeping employees safe and comfortably cool, manufacturers need to keep valuable equipment inside their facilities from overheating.

Overheated IT equipment can lead to reduced life and reliability, damage to hardware, a slower network and costly system downtime. Indeed, technology research company Gartner has estimated the average cost of network downtime is $5,600 per minute.

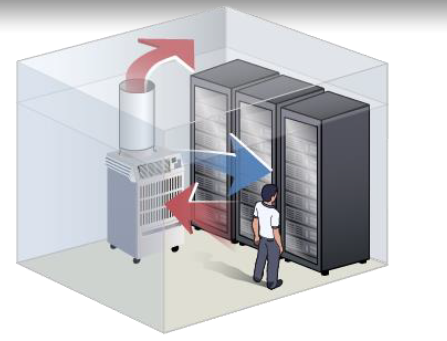

Solutions may include using a portable air-conditioning unit that can be introduced to an overheated server room to reduce heat stress on equipment and people to keep critical operations up and running. It can supplement existing cooling systems or act as a standby in the event the main cooling system fails.

This solution is useful because portable air conditioners may be programmed to keep running after employees leave for the evening, providing targeted cooling and saving money on energy use.

With assistance from Vanessa Jo Roberts.

Preventing Dehydration in the Workplace

Keeping your workers hydrated is crucial no matter the weather or time of year.

While the U.S. Occupational Safety and Health Administration (OSHA) does not provide a hydration standard, it does offer guidance on keeping workers safe in the heat.

To ensure your employees stay hydrated and safe, consider establishing a hydration program and putting some best practices in place.

A preliminary assessment of your workplace may include identifying hot or cold areas, the proximity of hydration stations to workers and whether water and electrolyte drinks can be placed on the plant floor.

Here are some other approaches to consider:

Keep water and electrolyte products readily available, as both help workers remain hydrated. The Mayo Clinic recommends 15 8-ounce cups of fluids per day for men and 11 for women. OSHA guidance suggests a cup of water every 20 minutes when working or exposed to hot or extreme environments.

Set up hydration stations in strategic locations and ensure they are equally accessible for all workers. If water supplies are not readily available near your workers, consider using ready-to-drink water bottles and pouches.

Explain and promote self-monitoring. The easiest way for workers to monitor their hydration levels is through the color of their urine. You can learn more about urine color and hydration here.

Use hydration signage to encourage self-care. This may include posting urine color charts in employee restrooms or locker areas and using signage to detail recommended drink consumption or remind workers how often to take hydration breaks.

Make good hydration part of your safety culture by including it in your routine training updates.

Related Articles

Accelerator-Free Gloves: Rethinking Hand Protection for Sensitive Skin

Worthy Waterproof Gloves You'll Want to Wear

![Why the Cheapest Safety Gloves Aren’t Always the Smartest [Infographic]](https://images.ctfassets.net/5j4ln2up7bt7/2gVEyRZylkBIlvTDtTRRc7/dde0c00e4846d6a88d56a7a68f09332a/mcr-PD5931_action4571-thumb.jpg)

Why the Cheapest Safety Gloves Aren’t Always the Smartest [Infographic]

NFPA 30 and Safe Storage of Flammable Liquids