In this episode of MSC's Tooling Up Toni Neary is joined by Patrick Sullivan, National Strategic Account Manager at Mitutoyo for a discussion on the quality and reliability of Mitutoyo’s trusted metrology tools.

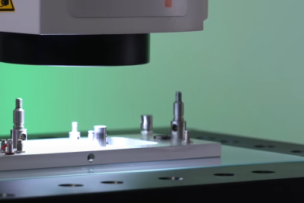

Ideal for non-contact measurements of workpieces and high-throughput production, Mitutoyo Vision Measurement Systems offer faster and more accurate edge detection, pattern recognition and measurements.

An oilfield couplings manufacturer in Houston, Texas increased productivity by 45% after investing in Mitutoyo's MeasurLink® electronic gaging solution.

Hexagon’s precision TESA-Hite gauges offer capabilities far beyond one-dimensional measurements, introducing buyers to some of the technological capabilities of Industry 4.0

This whitepaper explores four areas where manufacturers can reduce their operating costs by changing the way they control their machining processes.

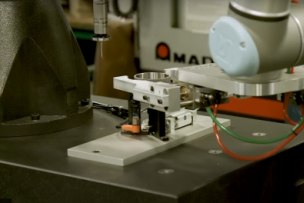

As manufacturers and machine shops ramp up recruitment and training to address a worsening shortage of qualified workers, they’re also leaning into technology for workarounds.

CMMs offer a capable, affordable and flexible gear inspection option.

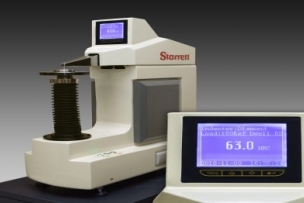

Understanding the different hardness testing types and systems can be useful to determine an optimal solution.

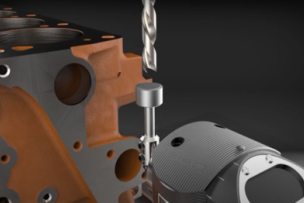

Identifying broken tools during the machining process is crucial to avoid excessive rework and the scrapping of components.

Using data collection technologies are a proven method to gain insights on dimensional measurement data that ultimately eliminates defects.