The ADF carbide flat drill, one of OSG Corporation’s latest drilling innovations, eliminates machining challenges such as cost, additional setup time and maintaining consistent hole quality, with one-step drilling.

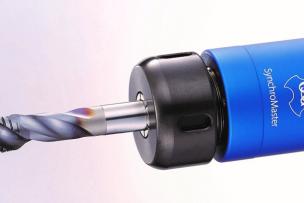

Machining troubles associated with tap processing are far more frequent in comparison to other rotating tools, such as drills and end mills. Manufacturers often struggle with threading applications because there are few effective solutions. OSG has recently introduced a new generation synchronized tap holder – the SynchroMaster – engineered to turbocharge performance by dampening excessive forces in rigid tapping environments.

Artificial intelligence is making its way into the manufacturing world. One AI expert weighs in on the numerous applications where AI will bear fruit.

Sometimes advertisements are too good to be true. But the ad for Sandvik's CoroCut QD for Y-axis parting tool lived up to its promises and has given American Valley Machining 500 to 600% gains on some operations.

When using conventional end mills on stainless steel, the cutting teeth entering and exiting the material create a natural rhythm that results in one of the most damaging forms of cutter wear known as chatter. With its patented, one of a kind geometry, the Z-Carb AP offers three stages of chatter suppression, resulting in the quietest, most stable milling experience available.

Titanium is widely used in many manufacturing industries, but it is not without its challenges. It is very chemically reactive and, therefore, tends to weld to the cutting tool during machining, thus leading to chipping and premature tool failure. Its low thermal conductivity increases the temperature at the tool/workpiece interface, which affects the tool life adversely. With these challenges in mind, the KYOCERA SGS Precision Tools technical team designed the Z-Carb High Performance Rougher.

An American machine shop in East Brunswick, New Jersey, that turns out complex landing-gear components for aircraft has cut machining times dramatically since introducing PrimeTurning.

A 5S methodology can help even a small machine shop identify and achieve process efficiencies, which in turn can lead to a rosier bottom line. Our infographic offers how to make the move to 5S.

MTS 2018 represents engineering solutions and technical expertise available to help customers overcome current and future machining challenges.

When working with machine tool builders (MTBs) involved in turnkey projects, each partner is deeply involved in the installation, adjustment and start-up work for technical and tooling equipment that is intended for the end-user.

.jpg?itok=hROn9gsl)