Hard turning has been used for decades to streamline and in many cases eliminate cylindrical grinding operations. But as the aerospace, automotive, power generation, and other industries continue to develop even more robust metals, cutting tool manufacturers must evolve as well with high-performance tooling to tackle these materials.

You can save more parts and adjust machines and tools faster with more accurate part quality measurements—which can be done closer to the work area than a metrology lab.

Training can help bridge the skills gap—but you’ll need a business strategy using ROI to help keep the program funded over the long haul.

Want to adopt 5-axis CNC machines but not sure it’s for you? Get real-world perspective from two manufacturers that did it.

Several key conference sessions at IMTS 2018 will focus on high-performance grinding—particularly for aerospace.

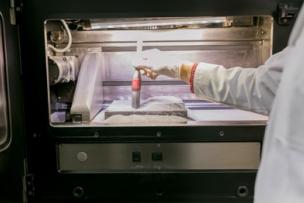

With a more inviting price point than other 3D technologies, 3D additive metal extrusion manufacturing has the potential to transform metalworking. Here’s an overview of the major players in this emerging space.

CFRP materials may be tough to cut, but the right tooling approach can make the difference.

For smaller job shops, bridging the skills gap may require competing with the big players in aerospace.

Projected to be a $15 billion market by 2025, the metalworking fluids industry is in a constant state of adaptation to regulations and reducing product use.