Enhanced durability, sensitivity and readability for metrology applications.

Deep hole drilling may seem difficult, but these simple steps from Manfred Lenz can help make it a trouble-free operation.

The global demand for stainless steel products has nearly doubled in the last 20 years and continues to grow 5% each year.

HAIMER's favorite (and best) piece of advice for customers is that balanced tool assemblies save time, reduce costs and increase tool life.

In any metal grinding or finishing application, it is important to have the correct product for the job.

A growing number of applications use aluminum in metal fabrication due to its high strength-to-weight ratio and superior corrosion resistance.

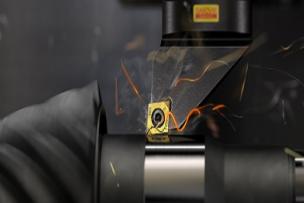

Machining parts at 50 HRc or more has traditionally been done by dedicated grinding equipment and processes.

The use of coolant and lubrication has a large impact on process security in many metal cutting applications.

You are aware that gloves provide vital protection from hand injuries in the workplace. You might know that gloves are also used for providing product protection, ensuring the quality of products being manufactured or handled. Given that gloves serve an important purpose, it is critical you and your employees wear the correct gloves.