Electric vehicles are nothing new. What is new, however, are autonomous electric vehicles that are produced on a massive 3D printer, then assembled by a small team of workers in a “microfactory.”

Aerospace manufacturers lean in to 3D-printable parts.

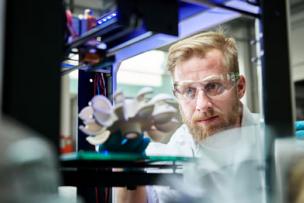

Though 3D printing has been around for decades, it has surged in popularity and usage in recent years.

Additive manufacturing offers a new way to reduce the weight of a milling cutter by 80% for better performance and up to 200% increased productivity.

What are the latest 3D-printed parts in aerospace, and how are they making an impact? We look at the evolution of additive manufacturing for this innovation-driven industry.

3D printing has moved from the hobbyist to a manufacturer’s part-design teams. How is it making an impact?

Beyond being a super-efficient way to engineer and build some aerospace parts, 3D additive manufacturing can take a big bite out of the total cost of operation.

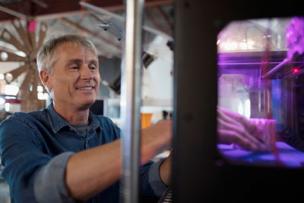

With a more inviting price point than other 3D technologies, 3D additive metal extrusion manufacturing has the potential to transform metalworking. Here’s an overview of the major players in this emerging space.

The new millennium poses revolutionary solutions for metal cutting applications.

Ryan Lawler gets a hand on look at Matterfab's new 3D metal printer and talks with co-founder Matthew Burris.