As robots continue their remarkable growth in metalworking and manufacturing facilities, employers need to know how to work safely with them. Read this Q&A from an industry expert.

There’s far more to automating production than plugging in a robot and turning it on. Here are some tips to get you started.

Industrial robots improve processes, increase output speed and boost returns on investment for manufacturers, but they also create new risks. Learn what you can do to keep employees safe in 21st-century manufacturing facilities.

In this episode of MSC's Tooling Up, Mitch Free is joined by Mike Shappell, Norton’s Senior Applications Engineer for a discussion on Norton Abrasive Process Solutions Lab, a fully custom, customer focused lab designed to automate your metal finishing needs.

3M Abrasives is helping to shape the future of automated abrasive processing.

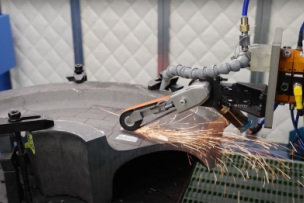

As the foundational technology underlying automation has reached new levels of sophistication and precision, metal fabricators are on the brink of yet another revolution: automated weld grinding.

When setting up robotic controls for a material removal abrasive process, 3M looks at several factors, including pressure.

The Abrasives Process Solutions Team from Norton | Saint-Gobain Abrasives provides a proof of concept for manufacturers to use automation for abrasives work.

Norton Abrasive's process solutions lab is a robotic-based system designed to assist the surface finishing industry.

If you're considering robotic deburring, finishing or other robotic abrasive operations, you'll likely need to work with a system integrator.

.jpg?itok=_wSk8UD2)