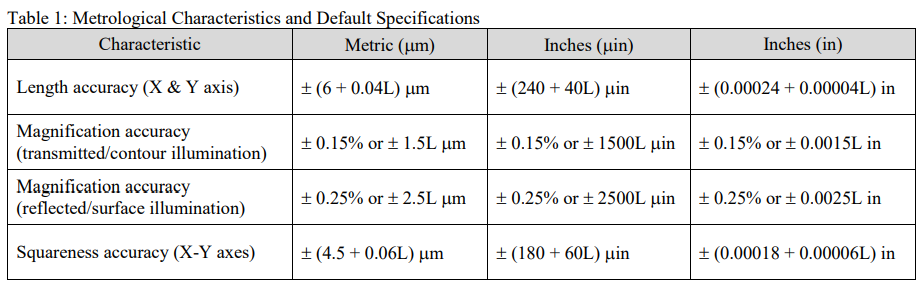

- For metric, L is length in mm. For inches, L is length in inches. The specifications in metric units are from JIS B 7184:1999. The inch units are converted with some minor rounding for convenience.

- For length accuracy, L is the measured length along the X or Y axis. For squareness accuracy, L is the maximum measuring range of the profile projector in either the X or Y axis. For magnification accuracy, L is the length of the feature being measured, not the length of the image on the screen.

- For magnification accuracy, the percentage shown is the percentage of nominal magnification.

- These specifications are from the Japanese national standard, JIS B 7184:1999, and not from Mitutoyo or any other manufacturer of profile projectors. Any manufacturer may specify alternative values for some of the characteristics. Being default specifications, these values apply if nothing else is stated by the manufacturer or agreed upon between the customer and supplier.

- All specifications apply at 20°C.

Magnification accuracy influences any measurements made across the measuring screen. Length accuracy (X & Y axis) impacts any measurements made using the measuring stage along either the X or Y axis. If the measuring stage is moved along both axes for a measurement, then the squareness accuracy also influences the measurement error.

The maintenance and calibration of a profile projector may include additional tests, as needed. These may include, for example, stage parallelism, screen eccentricity, screen cross-hair accuracy, and measuring accuracy of a rotating screen.

Calibration and Verification

There are many different types of profile projectors, and a suitable calibration method must be developed based on the specific configuration of the measuring instrument and the calibration goals of the user. Described below are examples of methods suitable for calibration; alternative methods may also be sufficient. In each case, to demonstrate conformity, the test values shall be within the accuracy specifications as stated in Table 1 or as otherwise stated or agreed upon.

Length Accuracy (X & Y axis)

Using a glass scale that covers the measuring range of the profile projector, separately calibrate the X and Y axis by taking a test point approximately every 25 mm or 1 inch. The glass scale should be positioned approximately in the center of the measuring stage. The measured test value (or error) is determined by the difference between the indicating reading and the calibrated value of the glass scale.

The Mitutoyo series 182 Working Standard Scales were specifically designed for this type of calibration. The Mitutoyo America Calibration Lab in Aurora, Illinois, offers ISO/IEC 17025 accredited calibrations for many types of glass scales.

Magnification Accuracy

For magnification accuracy, two different measurement standards are needed. A smaller standard, such as a short glass scale, is placed on the measuring table and its image on the screen is compared with a larger standard (the same glass scale used to check the X and Y length accuracy often works well). It is important to check the magnification in multiple places across the measuring range of the screen.

Squareness (X-Y axes)

The X-Y squareness error is calibrated using a precision square, such as a steel square or appropriate glass standard. The reference surface of the square is first aligned to either the X or Y axis, and then the squareness error is measured while moving along the other axis. Due to the small measuring range of profile projectors, it is usually sufficient to determine the squareness using only two test points – one each near the limits of stage travel. The squareness is calculated in length units and not in angle. The precision square must be appropriately calibrated at the necessary test points. The Mitutoyo America Calibration Lab in Aurora, Illinois, offers ISO/IEC 17025 accredited calibrations for many types of precision squares.

Previously Featured on Mitutoyo's blog.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *