Maximizing Manufacturing Productivity

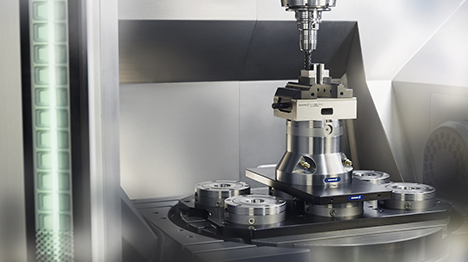

The trend in today's automotive manufacturing requires short production time yet a high degree of flexibility.

The trend in today's automotive manufacturing requires short production time yet a high degree of flexibility.

The automotive industry is one of the world's most important economic sectors, comprising a wide range of organizations in the development of motor vehicles utilizing the latest technologies. In the past couple of decades, automotive manufacturing has evolved significantly. Consumer appetite for greater performance, fuel-efficient and environmental friendly vehicles has become larger than ever before. A visible shift of energy source, materials and design prompts even more intricate processing of automobile components.

The trend in today's automotive manufacturing requires short production time yet a high degree of flexibility. To accommodate more complex machining, custom tooling can offer an additional solution to manufactures seeking maximum result.

To accelerate productivity, an increase in cutting speed and feed rate is often required. However, by simply increasing the speeds and feeds, greater cutting force is generated, which in turn creates more vibrations that puts higher stress on the tool cutting edge. With excessive vibrations and stress, poor hole quality and short tool life become the common unfavorable end results. Moreover, for countries such as Japan where space is limited, machines are trending to become more compact along with a more simplified jig setup. With a less powerful machine and a less rigid setup, speeds and feeds cannot be easily raised.

There is a clear correlation between the cutting velocity and feed rate with thrust force and drilling torque. When the drilling thrust exceeds the material bond strength, damages can be caused around the hole. To increase productivity in drilling by cutting speed and feed rate acceleration, low thrust is an absolute prerequisite. As shown in figure 1, thrust force is the highest point in the center of the drill. To suppress thrust force, drills are designed with wider chip pocket to improve chip evacuation as shown in figure 2. In this case study we will examine two applications where the wider chip pocket geometry was able to facilitate greater performance in terms of efficiency and quality.

Manufacturer Challenge: To further improve cycle time in S40C

Solution: The adoption of a custom 10mm dia. TRS 3-flute carbide step drill with low thrust geometry

Cutting speed and feed rate (before): V=80m/min, 509mm/min (f=0.2mm/rev)

Cutting speed and feed rate (after): V=100m/min, 1,273mm/min (f=0.4mm/rev)

Result: Cutting speed and feed improved by 2.5 times

Cutting speed and feed rate are the main parameters that influence thrust force and hole quality. An increase in cutting speed will lead to the increase of drill wear and thrust force. With the adoption of a custom step drill, the manufacturer was able to control thrust force for higher productivity.

Manufacturer Challenge: To minimize tool exchange frequency and to eliminate reamer processing time

Solution: The adoption of a custom drill with low thrust geometry to reduce stress on workpiece, maintain high hole precision and eliminate the need of a reaming tool

Reamers are generally used for finishing. With the adoption of a combo tool, a single tool was able to complete two different processes yet maintain the required hole accuracy. The result was a greatly simplified tool management and reduced cycle time.

Note: *Drilling products introduced in applications 1 and 2 are customized tooling based on standard OSG catalog items.

In addition to custom drilling solutions, this case study will also examine a threading application featuring OSG's XPF form tap series, which is engineered to generate up to 50 percent less torque versus other forming taps in the market, making it feasible for longer life at faster speeds in materials up to 35 HRC.

Manufacturer Challenge: Unstable chip evacuation

Solution: The adoption of the XPF forming tap

Result: The conventional spiral cut tap had a tool life of 300 holes. The XPF, on the other hand, was able to complete 2,000 holes stable. As forming tap forms screw threads through plastic deformation of work material, no cutting chips are created. With no cutting chips, chip evacuation troubles can be completely avoided.

In this application, although the processing only required a short tapping length, the work material was difficult to machine. Its properties have a tendency to generate inconsistent cutting chips, which would result in tool damage and breakage. When the manufacturer shifted focus on creating better chip separation by reducing the speed rate, gouging of the threads occurred. The slowing of tapping speed generates less heat. However, it would also cause greater cutting resistance and tool wear.

The XPF has significantly reduced friction resistance by adopting a special threading design and surface treatment. This results in a reduction in torque versus traditional products and a considerable suppression of heat generation.

Note: **Machining tips regarding the use of thread forming tap

Because plasticity varies depending on work materials, proper adjustment may be needed based on hardness and required accuracy of thread.

The automotive industry has been evolving rapidly in recent years through the new discovery of materials and technologies, prompting the need of sophisticated cutting tools capable of accommodating these new requirements. OSG is continuing to evolve and responding to changing needs through new innovations. OSG not only supplies powerful standard cutting tools for the automotive industry, but also provides tailored application solutions to help give manufacturers an extra boost to their production floor.

Previously featured on OSG Global Tooling Magazine.

To view OSG products, please visit MSCdirect.com.

OSG® is known worldwide for manufacturing premium round cutting tools for the metalworking industry. OSG remains focused on producing the highest quality and most consistent performing threading, drilling and milling tools. OSG provides a total solution of metalworking tools including spiral point taps, jobber length drill bits, square end mills, ball end mills and roughing end mills.