VIDEO: 60sec Troubleshooting: Threading: Tension Compression vs Rigid Tapping

Learn better ways to hold your tap than just a tension-compression holder where you don’t have to worry about over-cutting threads in this short video.

Learn better ways to hold your tap than just a tension-compression holder where you don’t have to worry about over-cutting threads in this short video.

Do you know the better ways to hold your tap than just a tension-compression holder where you don’t have to worry about over-cutting threads? Find out in this short video from OSG.

Previously Featured on OSG's YouTube channel.

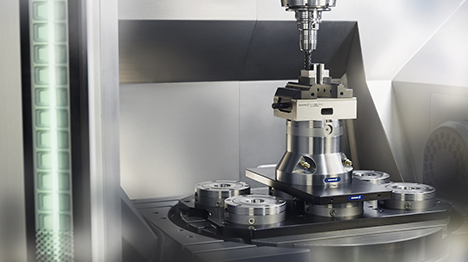

Welcome to OSG's 60-second troubleshooting video. One of the most common methods of holding a tap in a CNC machine is a tension compression holder. This style allows movement towards the spindle in compression and away from the spindle in tension. This style is useful for older and non-synchronized CNC machines, allowing the holder to compensate for imperfect matching of speed and feed especially during reversal, avoiding over cutting of the threads.

However, that movement allowed can induce over cut threads on synchronized machines. As the tap cuts the material, a spiral flute will pull itself forwards acting on the tension allowed. This is especially a concern in free-cutting materials such as aluminum.

To avoid this issue a solution is rigid tapping. This style is intended for synchronized spindles commonly found on newer CNC machines and it allows for zero movement either in tension or compression. This means though the tap may attempt to move in the holder, the holder will resist, preventing overfeeding.

Thank you for watching. For more information visit https://www.osgtool.com/.

OSG® is known worldwide for manufacturing premium round cutting tools for the metalworking industry. OSG remains focused on producing the highest quality and most consistent performing threading, drilling and milling tools. OSG provides a total solution of metalworking tools including spiral point taps, jobber length drill bits, square end mills, ball end mills and roughing end mills.