Miniature Feed Milling Solutions

ISCAR’s unique, small diameter, high feed indexable families expand the range of indexable lines for high feed milling, offering a productive replacement for solid carbide end mills

ISCAR’s unique, small diameter, high feed indexable families expand the range of indexable lines for high feed milling, offering a productive replacement for solid carbide end mills

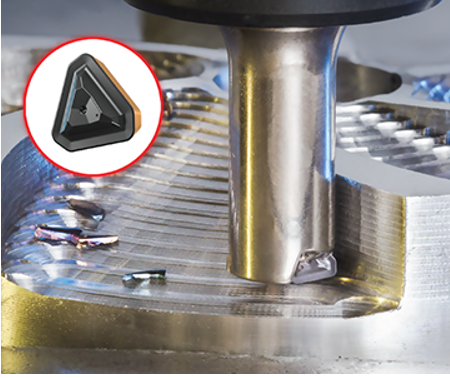

High Feed Milling has long been known for being a stable and effective rough milling approach on light-duty machines or milling processes with rigidity concerns. ISCAR’s unique, small diameter, high feed indexable families (MICRO 3 FEED and NAN 3 FEED) further expand the range of indexable lines for high feed milling, offering a productive replacement for solid carbide end mills when a high feed rough milling approach, which only uses the end of the tool, is warranted.

Both families are available with integral shanks and in ISCAR’s user-friendly, quick-change, MULTI-MASTER connections known for saving time on indexing, maximizing machine up time, and reducing errors due to eliminating the need for tool length offset procedures.

One of the main benefits of the Multi-Master system is the versatility to build a tool assembly to various lengths using a wide variety of shanks made from steel, carbide and heavy metal. There’s also integral tool holder and ER collet options that are ideal for increasing rigidity and reducing tool gage lengths when needing to work in tight areas. When extended length reach is needed, combining high feed indexable tooling with heavy metal shanks is an excellent combination for reducing vibrations and optimizing rough milling applications.

The MICRO 3 FEED family is available in diameters from .394” – 1.000" (10mm – 25.4mm), with depth of capability of 0.024” and feed rates up to 0.031”/tooth. This cutter system utilizes triangular shaped inserts with 3 cutting edges per insert.

The NAN 3 FEED family is available in 8mm (.315”) and 10mm (.394”) diameters and is capable of .024” depth of cut at feed rates up to 0.024”/tooth. This cutter system utilizes a triangular shaped insert offering 3 cutting edges and a wedge type insert clamping design, ensuring a strong design capable of high productivity and process reliability.

End users can expect to experience higher productivity utilizing the high-feed geometries, lower tooling cost compared to carbide based on the small multi-edge insert design, and a higher degree of process stability and reliability with these new designs.

What to look for: Machine shops that have lower power machines or where part fixturing is not stable/rigid and also when working in tight spaces. Iscar offers both solid round tools with high feed geometry as well as indexable options with up to 3 edges to reduce tooling cost.

See Iscar's NANO FEED Mill in action in this short video:

ISCAR supports world class manufacturing through continual advances in cutting tools technology. ISCAR's comprehensive line includes indexable inserts, end mills, toolholders, solid carbide drills and more. With innovative machining technology, ISCAR's tooling solutions will reduce cycle times, increase machine tool capacity and improve the profitability of your machine shop.