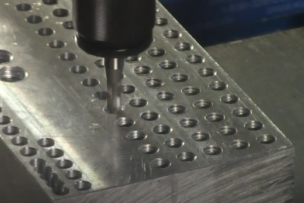

OSG is a leading manufacturer of taps, end mills, drills, and indexable cutting tools. OSG’s extensive line of high technology cutting tools features exclusive metallurgy, cutting geometries and proprietary surface treatments to help increase productivity, reliability and tool life.

OSG is determined to achieve continuous growth by contributing to the advancement of manufacturing industries worldwide. Gaining the support and trust of our customers has always been the commitment of OSG.

As a comprehensive cutting tool provider with operations spanning across the globe, OSG is committed to contributing to the advancement of the manufacturing industries by shaping our customers’ dreams into reality.

Talk to Us!

Leave a reply

Your email address will not be published. Required fields are marked *